In November 2024, I received an inquiry from a customer from Kazakhstan about galvanized threaded fittings. The inquiry include ELBOW, NIPPLE, COUPLING, TEE, UNION, etc., and the material is ASTM A105 galvanized. They are also the main products of our company.

In January 2025, the customer informed us that the project is undergoing final evaluation. The customer confirmed the order details and the quality requirements of the product. We can meet the customer’s needs.

On January 22, we received the customer’s purchase contract.

Purchase Order

| ITEM | DESCRIPTION | Connection Type | Size (DN) |

| ELBOW 90 DEG | ASTM A105 CS-HDG, CL 3000# | FNPT | 3/4″ (20) |

| 1/2″ (15) | |||

| 1/4″ (8) | |||

| ELBOW 45 DEG | ASTM A105 CS-HDG, CL 3000# | FNPT | 3″ (80) |

| 2″ (50) | |||

| EQUAL TEE | ASTM A105, CS-HDG, CL 3000# | FNPT | 3″ (80) |

| 2″ (50) | |||

| 1″ (25) | |||

| Reducing TEE | ASTM A105, CS-HDG, CL 3000# | FNPT | 3″ x 2″ |

| 3″ x 1″ | |||

| 2″ x 1/2″ | |||

| NIPPLE | ANSI B 16.11, 3000#, , A105 (HDG) – 75 mm LG | MNPT | 3″ (80) |

| 2″ (50) | |||

| 1-1/2″ | |||

| NIPPLE | ANSI B 16.11, 3000#, , A105 (HDG) – 200 mm LG | MNPT | 1-1/2″ |

| REDCUING COUPLING | REDCUING COUPLING, NPT, ASTM A105, CS-HDG, CL 3000# | FNPT | 1″ x 3/4″ |

| REDCUING COUPLING | 3/4″x1/2″ | ||

| UNION | UNION, ASTM A105, CS-HDG, NPT, CL 3000# | FNPT | 3″ |

| 2″ | |||

| 1-1/2″ | |||

| ELBOW 90 DEG | ASTM A105 CS-HDG, CL 3000# | FNPT | 2″ (50) |

| 1″ (25) | |||

| 3/4″ (20) | |||

| EQUAL TEE | ASTM A105, CS-HDG, CL 3000# | FNPT | 2″ (50) |

| 1″ (25) |

On February 20, this order was delivered as scheduled, and the product photos are as follows.

Hot Dip Galvanized (HDG) Threaded Fittings

Hot Dip Galvanized (HDG) Threaded Fittings are steel or iron pipe fittings that have been coated with a layer of zinc through the hot-dip galvanization process. This coating provides excellent corrosion resistance, making them ideal for use in harsh environments, including plumbing, water distribution, industrial applications, and outdoor settings.

ASTM A105 Threaded Fittings

ASTM A105 threaded pipe fittings are made of carbon steel and are connected by processing threads. Its main features are easy and quick connection, no welding equipment required, and are suitable for pipeline systems that are not easy to weld or require high connection flexibility.

ASTM A105 Threaded Fittings Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

ASTM A105 Threaded Fittings Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

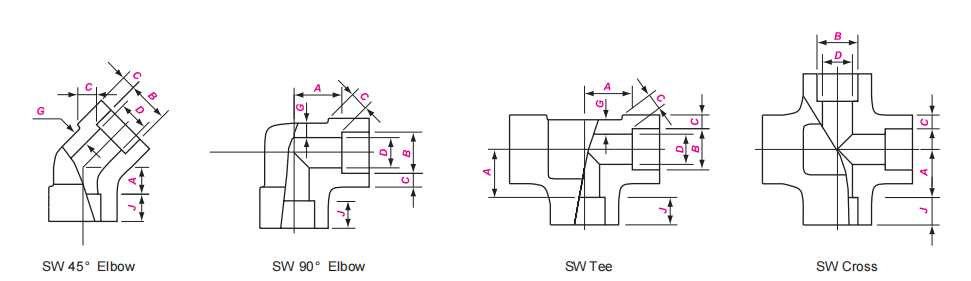

Threaded Fittings Dimension

| Threaded 45 Elbow | Threaded 45 ° Elbow | Threaded Tee | Threaded Cross | ||||||||||||

| GB/T 14383 ASME B16.11 | |||||||||||||||

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||||||

| DN | NPS | A | H | G min | L5 min | L2 min | |||||||||

| 90° Elbows, Tees, Crosses | 45 ° Elbows | ||||||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

| 6 | 1/8 1/4 3/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1 1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1 1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 53 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2 1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33 |

Key Features of HDG Threaded Fittings (FNPT)

Corrosion Resistance – The zinc coating protects against rust and oxidation, increasing the fitting’s lifespan.

Durability – Suitable for high-pressure and high-moisture environments.

Thread Standards – Typically follow NPT (National Pipe Thread) standards, with:

FNPT (Female National Pipe Thread) – Internal threads

Common Materials – Usually made from malleable iron or cast steel for strength.

Applications – Used in water systems, gas lines, industrial piping, and outdoor installations.

Hot Dip Galvanized vs. Other Galvanizing Methods

| Type | Process | Coating Thickness | Durability |

| Hot Dip Galvanized (HDG) | Fully submerged in molten zinc | 50-150 μm | Best (50+ years) |

| Electro-Galvanized | Zinc applied via electroplating | 2-25 μm | Weaker (1-10 years) |

| Pre-Galvanized (GI Steel) | Zinc coated before fabrication | 10-50 μm | Moderate (10-30 years) |

| Cold Galvanizing (Zinc Paint) | Zinc-rich paint applied | <10 μm | Lowest (Short-term protection) |