JIS G3454 Carbon Steel Pipe is a Japanese standard for carbon steel pipes that are used for pressure conditions. These pipes are used in a variety of industries, including oil and gas, water supply, and construction.

Mechanical properties of JIS G3454 can be varied greatly by heat treatment. Through a controlled cycle of heating and cooling, certain desired properties are obtained by producing predictable changes in the microstructure of the steel.

JIS G3454 carbon steel pipes are manufactured as per JIS Specifications. JIS G3454 carbon steel pipes’ mechanical properties can be varied greatly by heat treatment. JIS G3454 carbon steel pipe specification covers carbon steel pipe for machine structural purposes. JIS G3454 carbon steel pipes are used for pressure conditions at a limited maximum temperature of 350℃.

What does JIS stand for in steel?

Japanese Industrial Standards (JIS) (日本産業規格, Nihon Sangyō Kikaku, formerly 日本工業規格 Nihon Kōgyō Kikaku until June 30, 2019) are the standards used for industrial activities in Japan, coordinated by the Japanese Industrial Standards Committee (JISC) and published by the Japanese Standards Association (JSA).

JIS stands for Japanese Industrial Standards, which are used to define steel grades in Japan. JIS standards are also used in other industrial applications in Asia and the Pacific.

How are JIS standards used?

JIS steel specifications have been used as a base for other national systems, such as Korean, Chinese, and Taiwanese.

JIS standards enhance production efficiency by streamlining production processes, lowering costs, and optimizing operations.

What material is JIS G3454?

JIS G3454 applies to carbon steel pipes used in high-temperature and high-pressure applications. The standard covers seamless and welded pipes. Materials: The primary materials include various grades of carbon steel that meet the mechanical and chemical requirements specified in the standard.

JIS G3454 Carbon Steel Grade STPG 370 Specification Covers Carbon Steel Tubes for Pressure Service. ZIZI offer CS JIS G3454 available grades STPG 410, STPG 370 and a diverse range of finish options to meet the appearance requirements and performance for most applications.

JIS G3454 CS Pipe Specification

| Size | 21.3mm to 1219.2mm |

| Wall Thickness | 2-50mm |

| Length | max 12000mm |

| Standard | JIS G3454, JIS G3445, JIS G3452, JIS G3444 |

| Grade | STPG370, STPG410, STKM13A, STKM14A, SGP, STK290, STK400, STK500 |

| Steel grade | STPG 38, STPG 42 |

| Application | Carbon Steel Pipes for Pressure Service |

| Dimension Range | 10.5-660.4 mm |

Method of Manufacture

The pipe shall be manufactured by either the seamless of the electric resistance welding process.

(Applicable til the end of 1990) The pipe shall stay as manufactured. However, the cold- finished steel pipe shall be annealed after manufacture.The purchaser may specify heat treatment for the weld of the electric resistance welded steel pipe of grade STPG 42, as necessary.

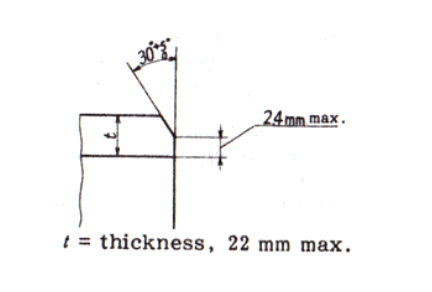

When required by the purchaser, the pipe may be furnished with a becwl end(1)

Note (1) Unless otherwise specified, the shape of the bevel end shall be as shown in Fig. 1.

JIS G3454 Carbon Steel Pipe Chemical Composition

| Grade | Chemical Composition% | ||||

| C | Si | Mn | P | S | |

| STPG 370 | 0.25 max | 0.35 max | 0.30~0.90 | 0.040 max | 0.040 max |

| STPG 410 | 0.30 max | 0.35 max | 0.30~1.00 | 0.040 max | 0.040 max |

Mechanical Property of CS G3454

| Letter symbol of grade | Tensile strength | Yield point or proof stress | Elongation % | |||

| kgf/mm2 {N/mm2} | kgf/mm2 {N/mm2} | No.11 and No.12 test pieces | No. 5 test pieces | No. 4 test piece | ||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STPG 370 | 38 {373}min | 22{216} min | 30 min | 25 min | 23 min | 28 min |

| STPG 410 | 42{412}min | 25{245} min | 25 min | 20 min | 19 min | 24 min |

Carbon Steel Pipes Pressure Service of JIS G3454

| KS | ASTM | JIS | DIN | BS | |||||

| GRADE | GRADE | GRADE | GRADE | GRADE | |||||

| D 3562 | SPPS 370 SPPS 38 | A 53 A 135 | Gr A Gr A | G-3454 | STPG 370 (STPG 38) | 1626 1628 1629 1630 17172 | St 37.0 St 37.4 St 37.0 St 37.4 StE240.7 | 3601 778 | ERW 360 S 360 HFS 22 CDS 22 ERW 22 |

| SPPS 410 SPPS 42 | A 53 A 135 | Gr B Gr B | STPG 410 (STPG 42) | 1626 1628 1629 1630 17172 | St 44.0 St 44.4 St 44.0 St 44.4 StE290.7 | 3601 | ERW 360 S 360 HFS 27 CDS 27 ERW 27 | ||

What is the meaning of STPG pipe?

“STPG pipe” refers to a carbon steel pipe for pressure service, where “STPG” stands for “Steel Tube Piping General” – essentially indicating a type of steel pipe suitable for high-pressure applications, typically following the Japanese Industrial Standard (JIS) G3454 specification:

Material: Carbon steel

Application: Used in situations requiring high pressure, like oil and gas pipelines, chemical processing, and power generation

Standard: Usually follows the JIS G3454 standard

Manufacturing process: Can be either seamless or welded depending on the specific application and grade.

What is the pressure rating of JIS?

In the JIS standard, the pressure rating is typically denoted by a “K” value, where “10K” indicates a pressure rating of 10 kg/cm² (kilograms per square centimeter), meaning a JIS 10K flange can withstand a pressure of 10 kg/cm²; other common JIS pressure ratings include 5K, 16K, 20K, 30K, and 63K depending on the specific application.

“K” signifies pressure:

The “K” in “JIS 10K” represents the pressure rating in kilograms per square centimeter.

Varying pressure levels:

Different “K” values indicate different pressure capabilities, with higher “K” numbers signifying higher pressure resistance.

JIS G3454 Carbon Steel Pipe Dimension

| Nominal size | Outside diameter (mm) | Carbon steel pipes for ordinary piping <SGP> (JIS G3452) | Carbon steel pipes for pressure service <STPG>(JIS G3454) | ||||||

| Nominal thickness | |||||||||

| A | B | Thickness (mm) | Sch10 | Sch20 | Sch30 | Sch40 | Sch60 | Sch80 | |

| 6 | 1/8 | 10.5 | 2 | – | – | – | 1.7 | 2.2 | 2.4 |

| 8 | 1/4 | 13.8 | 2.3 | – | – | – | 2.2 | 2.4 | 3 |

| 10 | 3/8 | 17.3 | 2.3 | – | – | – | 2.3 | 2.8 | 3.2 |

| 15 | 1/2 | 21.7 | 2.8 | – | – | – | 2.8 | 3.2 | 3.7 |

| 20 | 3/4 | 27.2 | 2.8 | – | – | – | 2.9 | 3.4 | 3.9 |

| 25 | 1 | 34 | 3.2 | – | – | – | 3.4 | 3.9 | 4.5 |

| 32 | 1 1/4 | 42.7 | 3.5 | – | – | – | 3.6 | 4.5 | 4.9 |

| 40 | 1 1/2 | 48.6 | 3.5 | – | – | – | 3.7 | 4.5 | 5.1 |

| 50 | 2 | 60.5 | 3.8 | – | 3.2 | – | 3.9 | 4.9 | 5.5 |

| 65 | 2 1/2 | 76.3 | 4.2 | – | 4.5 | – | 5.2 | 6 | 7 |

| 80 | 3 | 89.1 | 4.2 | – | 4.5 | – | 5.5 | 6.6 | 7.6 |

| 90 | 3 1/2 | 101.6 | 4.2 | – | 4.5 | – | 5.7 | 7 | 8.1 |

| 100 | 4 | 114.3 | 4.5 | – | 4.9 | – | 6 | 7.1 | 8.6 |

| 125 | 5 | 139.8 | 4.5 | – | 5.1 | – | 6.6 | 8.1 | 9.5 |

| 150 | 6 | 165.2 | 5 | – | 5.5 | – | 7.1 | 9.3 | 11 |

| 200 | 8 | 216.3 | 5.8 | – | 6.4 | 7 | 8.2 | 10.3 | 12.7 |

| 250 | 10 | 267.4 | 6.6 | – | 6.4 | 7.8 | 9.3 | 12.7 | 15.1 |

| 300 | 12 | 318.5 | 6.9 | – | 6.4 | 8.4 | 10.3 | 14.3 | 17.4 |

| 350 | 14 | 355.6 | 7.9 | 6.4 | 7.9 | 9.5 | 11.1 | 15.1 | 19 |

| 400 | 16 | 406.4 | 7.9 | 6.4 | 7.9 | 9.5 | 12.7 | 16.7 | 21.4 |

Tolerances on Outside Diameter and Wall Thickness of Carbon Steel Pipe

| Division | Tolerances on outside diameter | Tolerances on wall thickness |

| Hot-finished seamless steel pipe | 40 A or under 0.5mm | Under 4mm +0.6mm -0.5mm 4mm or over 15% -12.5% |

| 50A or over up to and incl. 125 A 1% | ||

| 150A 1.6mm | ||

| 200A or over 0.8% | ||

| For the pipe of nominal size 350 A or over, the tolerances on outside diameter may be determined by the measurement of the length of circumference. In this case, the tolerances shall be 0.5%. | ||

| Cold-finished seamless steel pipe and electric resistance welded steel pipe | 25 A or under 0.3mm | Under 3mm 0.3mm 3mm or over 10% |

| 32 A or over 0.8% | ||

| For the pipe of nominal size 350 A or over, the tolerances on outside diameter may be determined by the measurement of the length of circumference. In this case, the tolerances shall be 0.5%. |

What is the difference between JIS and ASME?

JIS (Japanese Industrial Standards) ball valves are designed to meet the requirements of the Japanese market and are commonly used in Asia. ASME (American Society of Mechanical Engineers) standards provide guidelines for the design, construction, and testing of various types of valves, including ball valves.

JIS and ASME flanges can be made from carbon steel, stainless steel, and other alloy steels.

JIS flanges are designed for specific pressure levels, such as 5K, 10K, 16K, 20K, and 30K.

ASME flanges are designed for specific pressure levels, such as 150LBS, 300LBS, 400LBS, 600LBS, and 900LBS.

JIS flanges are commonly used in Asia, while ASME flanges are widely used globally.

Marking

Each pipe having passed the inspection shall be marked with the following items. However, the smaller pipes or other pipes specified by the purchaser may be bundled together and marked for each bundle by a suitable means. In both cases, the order of arranging the marked items is not specified.

When approved by the purchaser, a part of the items may be omitted.

(1) Letter symbol of grade

(2) Letter symbol indicating the manufacturing processes(3)

(3) Dimensions( 4 )

(4) Manufacturer’s name or its identifying brand

(5) Letter symbol denothing the supplementary quality requirement, Z

Note( 3 )

The letter symbol indicating the manufacturing processes(3) shall be as follows, provided that the dash may be omitted leaving a blank.

Hot-finished seamless steel pipe – S – H

Cold-finished seamless steel pipe- S – C

Electric resistance welded steel pipe other than hot-finished and cold -finished ones – E – G

Hot-finished electric resistance welded steel pipe- E – H

Cold-finished electric resistance welded steel pipe – E – C

Note( 4 )

The dimensions shall be expressed as follows.

Nominal diameter × Nominal wall thickness

Example: 50A × Sch 40, 2 B × Sch 40

Testings

- Chemical analysis

- Tensile Test

- Flattening Test

- Bending Test

- Hydrostatic Test or Nondestructive Examination

You can get an offer for products in below material forms:

-Pipe and Tube (EN 10216-5, ASTM A213, ASTM A249, A312, A790,)

-Forged Fitting and Flange (ASTM A182 , ASTM A105,ASTM B564 )

-Butt Weld Fittings (ASTM A234, ASTM A403,ASTM A815)

-Round bar , Billet (ASTM A276, ASTM A479)

– Plate, Sheet, Strip(ASTM A240, EN 10028-7, A480)

-Bolting, Nuts(ASTM A193, A194, A320)

JIS G3454 Carbon Steel Pipe Exported Countries

We Export JIS G3454 Carbon Steel Pipe to Saudi Arabia, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen , Syria, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Cambodia, Argentina, Bolivia, Brazil, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Jamaica, Bahamas, Denmark, Norway, Germany, France,Italy, United Kingdom, Spain, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Finland, Ireland, Croatia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Europe, Africa, Asia, North America, South America, Middle East.etc