On 8th ,July, 2024. our regular client Mr Yane from Modern Range Trading in Saudi Arabia asked us to provide ASTM A105N Threaded Coupling as below:

COUPLING, PIPE;

TYPE:FULL, DIAMETER:1-1/2 IN, CONNECTION TYPE:FNPT,

MATERIAL:CS, MATERIAL GRADE:ASTM A105N,

OPERATING PRESSURE:CL 3000,

TEST CERTIFICATE REQUIRED:MTC,

STANDARD:ASME B16.11;

FFT: PROCESS: FORGED;

At 20th, July. He required to deliver them within 3 days, and Purchase order was awarded at the same time. On 23th, July,2024. Goods have been completed on time and transported by International Express under DDP.

Shanghai Zhucheng Pipe Fittings Manufacturing Co Ltd manufacture & supply ASTM A733 threaded pipe nipples and threaded couplings with different materials such as carbon steel,stainless steel and alloy steel.We are one of the biggest manufacturers and suppliers of pipe fititngs in China,our products contain butt welding pipe fittings,forged pipe fittings,steel pipes and flanges.

Inspection photos are as follows:

ASTM A105N Threaded Coupling Specification

ASTM A105N threaded couplings are used in piping systems to connect two pipes with threaded ends. They are made from carbon steel conforming to ASTM A105N, a normalized grade of ASTM A105, which enhances its mechanical properties and improves toughness.

| Types | Full Coupling , Half Coupling |

| Shapes | Con-coupling , Red-coupling |

| Normal Size | 1/8”– 4” / DN6 – DN100 |

| Class | Class 3000lbs , 6000lbs |

| Production Standard | ASME B16.11, BS3799, GB/T 14383 |

| Thread mode | NPT, PT, BSPP, BSPT, PF |

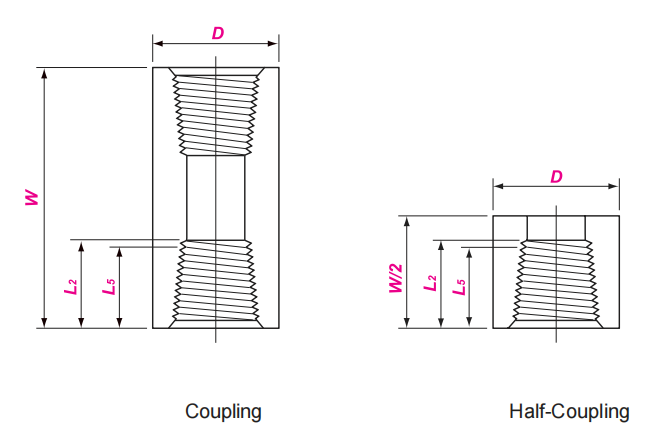

Types of Threaded Couplings

Full Coupling

– Connects two pipes of the same diameter.

– Fully threaded inside.

Half Coupling

– Has internal threads on one end and a plain end on the other.

– Used for branching off a pipe or welding one end to a larger structure.

ASTM A105N Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 | |

| ASTM A105N | MIN | 0.600 | |||||||||

| MAX | 0.350 | 1.050 | 0.040 | 0.050 | 0.400 | 0.300 | 0.120 | 0.080 |

ASTM A105N Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

| ASTM A105N | 485min | 250 min | 22 min | 30 min | 197 max |

ASME B16.11 Threaded Coupling Dimensions

| Nominal Size | End-to-End | Outside Diameter | Length of Thread | |||

| DN | NPS | W | D | L 5 min | L 2 min | |

| 3000 & 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1 1/4 | 67 | 57 | 64 | 17 | 18 |

| 40 | 1 1/2 | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19 | 19.2 |

| 65 | 2 1/2 | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 140 | 159 | 27.7 | 33 |

Forged Threaded Coupling Weight Chart in KG

| NOMINAL SIZE | THREADED COUPLING WEIGHT | ||

| DN | NPS | 3000# | 6000# |

| 6 | 1/8 | 0.06 | 0.09 |

| 8 | 1/4 | 0.08 | 0.13 |

| 10 | 3/8 | 0.11 | 0.24 |

| 15 | 1/2 | 0.22 | 0.4 |

| 20 | 3/4 | 0.3 | 0.52 |

| 25 | 1 | 0.55 | 1.06 |

| 32 | 1 1/4 | 0.86 | 1.32 |

| 40 | 1 1/2 | 1.26 | 2.2 |

| 50 | 2 | 1.65 | 3.37 |

| 65 | 2 1/2 | 3 | 4.81 |

| 80 | 3 | 4.25 | 7.25 |

| 100 | 4 | 7.8 | 12 |

Threaded Couplings Key Features

Connecting Pipes:

The primary function is to extend pipe runs or connect sections of piping.

Connecting Fittings:

They can also be used to join other threaded fittings, such as valves or other components.

Ease of Installation:

Threaded connections are relatively easy to install and disassemble, making them useful for applications where maintenance or modifications may be required.

Applications:

– Threaded couplings are found in a wide range of applications, including:

– Plumbing systems

– Industrial piping

– Pneumatic and hydraulic systems

– Irrigation systems