One new client from Morocco send me a inquiry about Socket Weld Fittings by email.

The next day, I marked the weight and prices for client, and quoted to him. I also attached the data sheet and sample MTC for him reference.

The client feedback that our quotation is professional and thanks for the data sheet and sample MTC which is helpful to win the order.

One month later, I followed the client by email. He reply me soon, and asked the data sheet and sample MTC again.

Another week passed, the client told me they got the order, and ask me provide the proforma invoice for him the payment.

Purchase Order List

| ITEM | DESCRIPTION | Size | Pressure | Material | Quantity | Unit |

| 1 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 1.1/2″ | 6000 lb | ASTM A105 | 60 | u |

| 2 | SEAMLESS S.W 45° ELBOW ASME B16.11 CS | 1.1/2″ | 6000 lb | ASTM A105 | 10 | u |

| 3 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 1.1/2″ | 3000 lb | ASTM A105 | 10 | u |

| 4 | SEAMLESS S.W EQUAL TEE ASME B16.11 CS | 1/2″ | 3000 lb | ASTM A105 | 20 | u |

| 5 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 1/2″ | 3000 lb | ASTM A105 | 70 | u |

| 6 | SEAMLESS S.W 45° ELBOW ASME B16.11 CS | 3/4″ | 3000 lb | ASTM A105 | 20 | u |

| 7 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 3/4″ | 3000 lb | ASTM A105 | 20 | u |

| 8 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 1.1/4″ | 3000 lb | ASTM A105 | 10 | u |

| 9 | SEAMLESS S.W 90° ELBOW ASME B16.11 CS | 1″ | 3000 lb | ASTM A105 | 130 | u |

| 10 | SEAMLESS S.W COUPLING ASME B16.11 CS | 1.1/2″ | 6000 lb | ASTM A105 | 15 | u |

| 11 | SEAMLESS S.W COUPLING ASME B16.11 CS | 1/2″ | 3000 lb | ASTM A105 | 40 | u |

| 12 | SEAMLESS S.W COUPLING ASME B16.11 CS | 3/4″ | 3000 lb | ASTM A105 | 20 | u |

| 13 | SEAMLESS S.W. COUPLING REDUCING ASME B16.11 CS | 1.1/2″-3/4″ | 3000 lb | ASTM A105 | 10 | u |

| 14 | SEAMLESS S.W COUPLING ASME B16.11 CS | 1.1/4″ | 3000 lb | ASTM A105 | 10 | u |

| 15 | SEAMLESS S.W COUPLING ASME B16.11 CS | 1″ | 3000 lb | ASTM A105 | 40 | u |

| 16 | SEAMLESS S.W. COUPLING REDUCING ASME B16.11 CS | 2″-1.1/2″ | 6000 lb | ASTM A105 | 6 | u |

ASTM A105 socket fittings are pipe fittings used to assemble pipe systems through socket connection, and are mainly made of carbon steel. Socket connection is to insert one end of the pipe fitting into the socket of another pipe fitting or pipe, and then seal it with sealing materials, and use a certain connection method to make the connection firm.

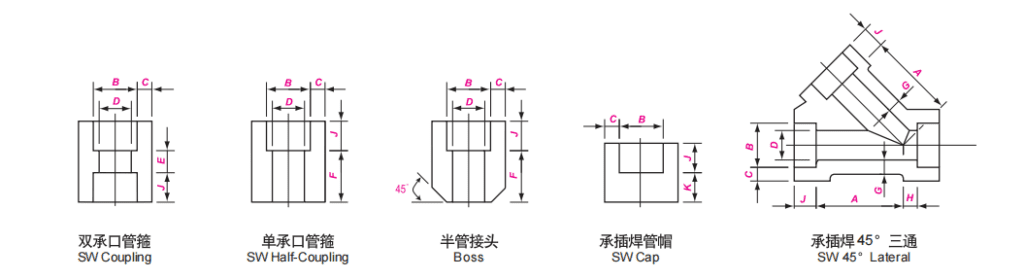

ASTM A105 socket weld fittings include elbow, tee, cross, cap, coupling, boss, and union.

Specification of Socket Weld Fittings

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

ASTM A105 Socket Weld Fittings Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

ASTM A105 Socket Weld Fittings Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

ASTM A105 Socket Weld Fittings Dimension

Nominal Size | Socket Bore Dia. | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Laying Lengths | Laying Lengths | End Wall Thickness | Center to Bottom of Socket | |||||||||||||||

| DN | NPS | B | D | C | G min | J min | E | F | K min | A | H | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 3000 | 6000 | |||||||||

| ave | min | ave | min | ave | min | |||||||||||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 6.5 | 17.5 | 4.8 | 6.4 | 37 | 9.5 | |||||||

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 9.5 | 22.5 | 6.4 | 7.9 | 11.2 | 41 | 51 | 9.5 | 11 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 9.5 | 24.0 | 6.4 | 7.9 | 12.7 | 51 | 60 | 11 | 13 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 12.5 | 28.5 | 9.6 | 11.2 | 14.2 | 60 | 71 | 13 | 16 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 12.5 | 30.0 | 9.6 | 11.2 | 14.2 | 71 | 81 | 16 | 17 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 12.5 | 32.0 | 11.2 | 12.7 | 15.7 | 81 | 98 | 17 | 21 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 19.0 | 41.0 | 12.7 | 15.7 | 19.0 | 98 | 151 | 21 | 30 |

How to inspect socket weld fittings?

Visual Inspection

The most basic and common inspection method to check the general condition and installation of socket weld fittings.

Ensure the pipe end is fully inserted into the socket of the fitting. There should be no visible gaps between the pipe and the fitting.

Check that the pipe and fitting are properly aligned. Misalignment can cause stress or failure later.

Visually inspect the weld for any obvious defects like cracks, porosity, or incomplete fusion.

The weld should be smooth and even, with a consistent bead. There should be no sharp edges, undercuts, or excessive weld metal.

Presence of Leaks: Look for any signs of leakage, especially around the weld area, even if there is no visible crack.

Dimensional Inspection

To ensure the fitting and pipe dimensions meet the design specifications and tolerances.

Measure the socket depth to ensure that the pipe is inserted to the correct depth for a proper weld.

Check that the pipe has been inserted fully into the fitting. An insufficient insertion depth can result in weak or incomplete welds.

Verify that the pipe is correctly centered in the fitting.

For threaded fittings, check that the threads are clean, undamaged, and fit correctly.

ASTM A105 Socket Weld Fittings Application

– Oil and Gas Industries

– Food Processing Industries

– Equipment

– Pipeline

– Power Industries

– Ship Building Industries

– Paper Industries

– Cement Industries

– Chemical Industries