ASTM A182 F22 is a specification for forged or rolled alloy steel pipe flanges, forged fittings, valves, and parts for high-temperature service. The material grade F22 is specifically made from a chromium-molybdenum steel alloy, which is designed to offer high-temperature and high-pressure resistance.

ZIZI is worldwide Manufacturer of ASTM A182 F22 Alloy Steel Forged Fittings, stand by the principles of safety and quality. We are suppliers and exporters of Alloy Steel A182 F22 Forged Threaded Fittings, which are forged used with pressure systems working at higher temperatures.

What is the ASME standard for forged fittings?

The American Society of Mechanical Engineers (ASME) B16.11 standard governs forged steel fittings, including socket weld and threaded fittings. The standard covers material requirements, dimensions, tolerances, pressure-temperature ratings, and markings.

Materials

Carbon steel, alloy steel, stainless steel, duplex stainless steel

Pressure ratings

Class 2000, 3000, and 6000 for threaded fittings, and Class 3000, 6000, and 9000 for socket weld fittings

Where are ASME B16.11 fittings used?

ASME B16.11 fittings are used in many industrial applications, including:

– Marine engineering

– Petrochemical plants

– Nuclear power projects

– Valves manufacturing

– Chemical processing

– Hydro-carbon processing

– Heat exchangers

– Pumps manufacturing

What are forged steel fittings?

Forged steel fittings are the fittings made by forged steel. The process of manufacturing forged steel fittings include: cutting and heating billets, put pressure on heated billets under dies into desired shape, trimming and shot blasting. Then machine forged blank fittings for net shape and dimensions.

According to the applications of forged steel fittings, they are available in threaded and socket weld end connections. The dimensions for socket weld forged steel fitting conform to ASME B16.11 and threaded forged steel fittings conform to ASME (American Society of Mechanical Engineers) B1.20.1.

How are they made?

– The steel is heated to a molten temperature

– The heated steel is placed in dies

– The steel is machined into the desired shape

What is F22 forging material?

F22 forging material is a low-alloy steel that contains chromium, carbon, molybdenum, and other elements. It’s used to make forged fittings, flanges, valves, and other components. F22 is often used in the oil industry for wellhead applications.

Properties

F22 is heat-treatable and deep-hardening

It has good weldability, strength, and impact properties

F22 is often used as the base metal for clad components

F22 is an upgrade over the AISI 4130 type of steel

ASTM A182 F22 Material Analysis

This specification covers forged low alloy and stainless steel piping components for use in pressure systems. Included are flanges, fittings, valves, and similar parts to specified dimensions or to dimensional standards, such as the ASME specifications that are referenced in Section 2.

Chemical Composition

A chemical heat analysis in accordance with Specification A961/A961M shall be made and conform to the chemical composition prescribed in Table 1.

Grades to which lead, selenium, or other elements are added for the purpose of rendering the material free-machining shall not be used.

Starting material produced to a specification that specifically requires the addition of any element beyond those listed in Table 1 for the applicable grade of material is not permitted.

Table 1 ASTM A182 F22 Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A182 F22 CL1,CL3 | MIN | 0.05 | 0.30 | 2.00 | 0.87 | |||

| MAX | 0.15 | 0.60 | 0.04 | 0.04 | 0.50 | 2.50 | 1.13 |

Mechanical Properties

The material shall conform to the requirements as to mechanical properties for the grade ordered as listed in Table 2.

Table 2 ASTM A182 F22 Mechanical Properties

| Grade Symbol | Tensile Strength, min,ksi [MPa] | Yield Strength, min,ksi[MPa]” | Elongation in 2 in. [50 mm]or 4D,min,% | Reduction of Area,min,% | Brienell Hardness Number,HBW, unless otherwise indicated |

| F22,Class 1 | 60 [415] | 30[205] | 20 | 35 | 170 max |

| F22,Class 3 | 75[515] | 45[310] | 20 | 30 | 156-207 |

Equivalent Grades of Alloy Steel F22 Forged Fittings

| Grade | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F22 | K21590 | 1.738 | 2-1/4Cr-1/2Mo-Vd |

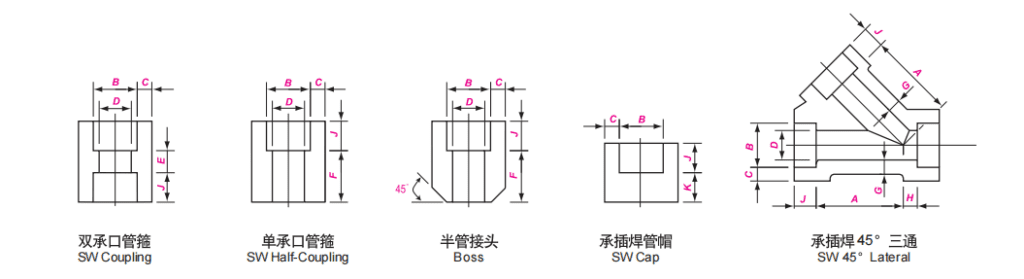

ASTM A182 F22 Socket Weld Fittings

ASTM A182 F22 socket weld fittings are a type of forged fitting specifically made from the F22 alloy steel, which is a chromium-molybdenum steel designed for high-temperature, high-pressure service environments. Socket weld fittings are a type of forged pipe fitting that is used to join two sections of pipe together. In a socket weld fitting, the pipe is inserted into a socket-shaped end, and then it is welded around the circumference. These fittings are commonly used in high-pressure, high-temperature applications, especially where the piping is relatively small (typically 2 inches or smaller in diameter).

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

Socket Weld Fittings Dimension

Nominal Size | Socket Bore Dia. | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Laying Lengths | Laying Lengths | End Wall Thickness | Center to Bottom of Socket | |||||||||||||||

| DN | NPS | B | D | C | G min | J min | E | F | K min | A | H | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 3000 | 6000 | |||||||||

| ave | min | ave | min | ave | min | |||||||||||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 6.5 | 17.5 | 4.8 | 6.4 | 37 | 9.5 | |||||||

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 9.5 | 22.5 | 6.4 | 7.9 | 11.2 | 41 | 51 | 9.5 | 11 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 9.5 | 24.0 | 6.4 | 7.9 | 12.7 | 51 | 60 | 11 | 13 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 12.5 | 28.5 | 9.6 | 11.2 | 14.2 | 60 | 71 | 13 | 16 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 12.5 | 30.0 | 9.6 | 11.2 | 14.2 | 71 | 81 | 16 | 17 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 12.5 | 32.0 | 11.2 | 12.7 | 15.7 | 81 | 98 | 17 | 21 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 19.0 | 41.0 | 12.7 | 15.7 | 19.0 | 98 | 151 | 21 | 30 |

| 65 | 2 1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16.0 | 19.0 | 43.0 | 15.7 | 19.0 | 151 | 30 | |||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.30 | 7.62 | 16.0 | 19.0 | 44.5 | 19.0 | 22.4 | 184 | 57 | |||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19.0 | 19.0 | 48.0 | 22.4 | 28.4 | 201 | 66 | |||||||||||

Advantages

● High-Temperature Resistance

● Enhanced Strength and Durability

● Corrosion and Oxidation Resistance

● Compact and Efficient Connection

● Easy Installation and Reliability

● Resistant to Pressure and Vibration

● Lower Maintenance Costs

● Suitable for Small-Diameter Piping

● Versatile Use in Critical Applications

In summary, ASTM A182 F22 Socket Weld Fittings provide a durable, reliable, and cost-effective solution for high-temperature, high-pressure, and corrosive environments, making them essential in industries that require secure and robust piping systems.

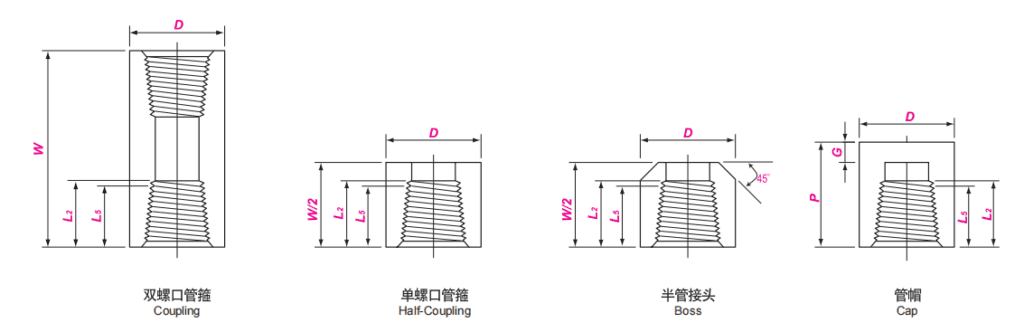

ASTM A182 F22 Threaded Fittings

ASTM A182 F22 threaded fittings are a type of forged fitting made from the F22 alloy steel (a chromium-molybdenum steel), designed for use in high-temperature and high-pressure systems. Threaded fittings are commonly used in piping systems to connect, join, or alter the direction of pipes without the need for welding. These fittings are threaded at the ends, and they can be screwed onto pipes or other fittings with matching threads. Threaded fittings are ideal for situations where welding is impractical, not allowed, or where a more temporary or flexible connection is needed.

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″- 4″/ DN6-DN100 |

| Pressure Rating | CL2000/3000/6000 |

| Standard | ASME B16.11 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

Threaded Fittings Dimension

| Nominal Size | End-to-End | End-to-End | Outside Diameter | End Wall | Length of Thread | |||||

| DN | NPS | W | P | D | G min | L 5 m in | L 2 m in | |||

| 3000 & 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 19 | 16 | 22 | 4.8 | 6.4 | 6.7 | ||

| 8 | 1/4 | 35 | 25 | 19 | 25 | 4.8 | 8.1 | 10.2 | ||

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1 1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1 1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2.5 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33 |

Advantages

● Ease of Installation:

● Cost-Effective:

● Leak-Proof Design:

● Corrosion Resistance:

● High-Temperature and High-Pressure Resistance:

● Reliability in Small and Medium-Sized Piping Systems:

● Flexibility for Disassembly and Reassembly:

● Wide Range of Applications:

In Summary, Threaded fittings made from ASTM A182 F22 provide ease of installation, corrosion and high-temperature resistance, and cost savings, making them an excellent choice for small to medium-sized piping systems that require strong, reliable connections. They are particularly useful in situations where welding is not practical, and quick assembly or disassembly is needed.

What is the difference between A182 F11 and A182 F22?

The primary differences between ASTM A182 F11 and ASTM A182 F22 lie in their chemical compositions, which in turn affect their mechanical properties and suitability for different applications. Here’s a breakdown:

Chemical Composition:

Both F11 and F22 are chromium-molybdenum (Cr-Mo) alloy steels, but they differ in the percentages of these alloying elements.

F22 generally has a higher chromium and molybdenum content compared to F11.1 This increase in alloying elements enhances its high-temperature strength and corrosion resistance.

Mechanical Properties:

Due to its higher alloy content, F22 typically exhibits:

Higher tensile strength

Improved creep resistance (resistance to deformation under sustained stress at high temperatures)

This makes F22 more suitable for more demanding high-temperature and high-pressure applications.

Applications:

Both are used in high-temperature service, but:

F11 is often used in moderate-temperature applications.

F22 is preferred for more severe high-temperature environments, such as those found in:

Power plants

Petrochemical refineries

High-pressure steam systems.

In essence, F22 is a “stronger” alloy than F11, better equipped to handle higher temperatures and pressures.

Therefore when very high heat or preassure is present, F22 is the better choice.

Tests we can carry out

– Positive material recognition

– Mechanical examining like tensile, Elongation and reduction of area.

– Large-scale test

– Chemical examination-Spectro analysis

– Firmness test

– Pitting protection test

– Small tests

– X-ray test

– Impact analysis

– Eddy current examining

– Hydrostatic analysis

– Prompt test

You can get an offer for products in below material forms:

-Pipe and Tube (EN 10216-5, ASTM A213, ASTM A249, A312, A790,)

-Forged Fitting and Flange (ASTM A182 , ASTM A105,ASTM B564 )

-Butt Weld Fittings (ASTM A234, ASTM A403,ASTM A815)

-Round bar , Billet (ASTM A276, ASTM A479)

– Plate, Sheet, Strip(ASTM A240, EN 10028-7, A480)

-Bolting, Nuts(ASTM A193, A194, A320)

ASTM A182 F22 Forged Fittings Exported Countries

We Export ASTM A182 F22 Forged Fittings to Saudi Arabia, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen , Syria, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Cambodia, Argentina, Bolivia, Brazil, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Jamaica, Bahamas, Denmark, Norway, Germany, France,Italy, United Kingdom, Spain, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Finland, Ireland, Croatia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Europe, Africa, Asia, North America, South America, Middle East.etc