ZIZI ENGEERING CO LTD is professional and experience in servicing and producing all types of pipe fittings. We are well known stainless steel pipe elbow manufacturer and supplier in China. We produce different ranges of stainless steel butt weld elbow and forged elbow. Our products are of superior quality and we supply to a wide variety of customer requirements. Depending on the nature of the application, the ASTM A403 BW elbow and ASTM A182 forged elbow could be used.

What is Stainless Steel Pipe Elbow

Stainless steel pipe elbow is a pipe fitting that connects two lengths of pipe or tubing to change the direction in piping and plumbing systems, common angles are having 45 degree, 90 degree and 180 degree, 304/304L and 316/316L stainless steel elbows can withstand high pressure and resist corrosion, duplex steels and nickel alloys are available.

We can offer stainless steel pipe elbows in a wide range of styles and sizes, butt weld steel pipe elbow fitting dimension ranges from 1/2 inch to 80 inch, The Schedule in wall thickness range covers 5S, 10S, 40S, 80S, 160S, and XXS conforming to ASME B16.9. Forged elbow fittings dimension ranges from 1/2 inch to 4 inch, pressure range Class 2000,3000,6000 and 9000 conforming to ASME B16.11.

Stainless Steel Material Grade

There are various stainless steels to be adapted for pipe elbow used in different applications, as we know that stainless steel exhibits excellent properties to resist corrosion, heating and high pressure, thus, stainless steel elbow is often used in critical applications.

ASTM A182 F304 and F316 are the most used stainless steel grades, they are both high chromium austenitic grades and can be met the most cases, and other grades are available, such as 321/321H and 347/347H. Some special alloys are usually for the elbow as well, like 904L, F51,F53.

Chemical Composition of Stainless Steel Pipe Elbow

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Ti | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | |||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | ||||

| ASTM A182 F316 | MIN | 10.00 | 16.00 | 2.00 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | 0.01 | |||

| ASTM A182 F321H | MIN | 0.04 | 9.00 | 17.00 | 4*C | |||||||

| MAX | 0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 | 0.7 | ||||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | |||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | |||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | |||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.50 | ||

| ASTM A182 F904L (N08904) | MIN | 23.00 | 19.00 | 4.00 | 1.00 | |||||||

| MAX | 0.02 | 2.00 | 0.040 | 0.030 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F304 | 515 min | 205 min | 30 min | 50 min |

| ASTM A182 F316 | 515 min | 205 min | 30 min | 50 min |

| ASTM A182 F321H | 515 min | 205 min | 30 min | 50 min |

| ASTM A182 F51 | 620 min | 450 min | 25 min | 45 min |

| ASTM A182 F53 | 800 min | 550 min | 25 min | 15 min |

| ASTM A182 F904L (N08904) | 490 min | 215 min | 35 min |

ASME B16.9 Butt Weld Elbow

ASME B16.9 standard is the American national standard for butt weld fittings. ASME B16.9 Standard covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought butt weld fittings in sizes NPS 1/2 to NPS 48 (DN 15 to DN 1200). It covers fittings of any producible wall thickness. This standard does not cover low pressure corrosion resistant butt weld fittings.

Stainless steel butt weld elbow is made of stainless steel as raw material, which is formed by hot pressing. It’s connection form is to directly weld the elbow to the steel pipe, thereby achieving the connection and turning of the pipeline. It have certain pressure resistance and can maintain a stable connection state in high-pressure environments.

Stainless steel pipe elbow plays a key role in the pipe fittings, which frequently used in different application and available in various shapes and sizes. It connects two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree, 90 degree or 180 degree.

| Material | ASTM A403 / ASME SA403 |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

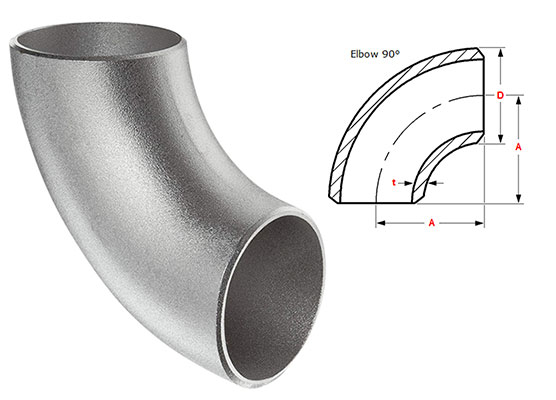

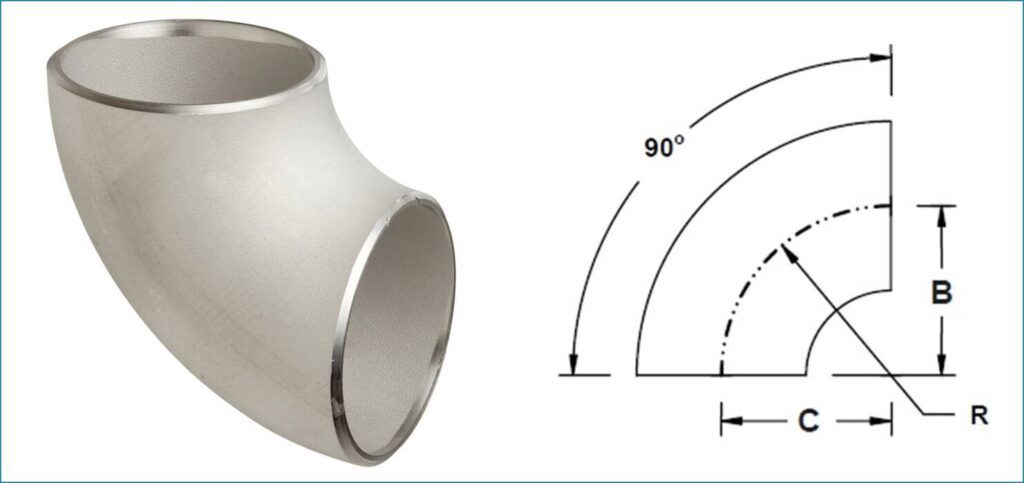

Butt Weld 90 Degree Stainless Steel Pipe Elbow

It is very common degree in the elbow fittings, and commonly used to change the fluid direction by 90 degree. Elbows are available in two radius types by length, Short radius (SR) and Long radius (LR), there are also other radius, for example, 2D, 3D and 4D.

Long Radius 90 Degree Elbow

We usually see them in the description of elbow as LR or 1.5D. That means LR = 1.5D and D is outside diameter.

Short Radius 90 Degree Elbow

They are named as SR or 1D in the description of elbow which mentioned above. So the bending radius is same as the outside diameter.

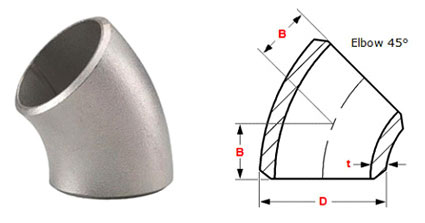

Butt Weld 45 Degree Elbow

45 degree elbow changes the flow direction to 45 degrees, it includes long radius 45 degree elbow and short radius 45 degree elbow.

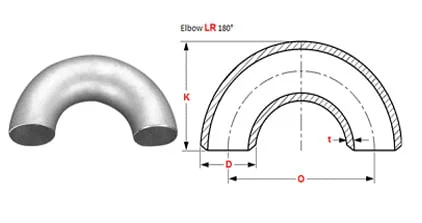

180 Degree Steel Pipe Elbow

We also call 180 Degree elbow as return elbow. It helps change direction at 180 degrees. Its application is limited to minimal deposition and low turbulence system.

Metal Elbows

Carbon Steel: Widely used due to its high strength and relatively low cost. Carbon steel 90 – degree elbows can withstand high pressures and are commonly found in industrial applications like oil refineries, power plants, and chemical processing facilities.

Stainless Steel: Known for its excellent corrosion resistance. Stainless steel elbows are often used in environments where the fluid being transported is corrosive, such as in food processing plants (due to hygiene requirements), pharmaceutical industries, and marine applications.

Copper and Brass: These metals are used for their good heat transfer properties and corrosion resistance in some applications. Copper 90 – degree elbows are frequently seen in plumbing systems for hot and cold water supply, especially in residential and commercial buildings.

Plastic Elbows

PVC (Polyvinyl Chloride): Lightweight, inexpensive, and highly resistant to chemicals. PVC 90 – degree elbows are commonly used in drainage systems, irrigation networks, and some low – pressure chemical piping systems.

PE (Polyethylene): Offers good flexibility and impact resistance. PE elbows are often used in applications where flexibility is required, such as in some agricultural and water distribution systems.

Package of Butt Weld Elbows

For the size of 1/2″ -8″ , the package type is crate.

8″ -12″ is Pallet, and above 12″ is loose.

However, the packaging can be customized according to the customer’s specific requirements.

ASME B16.11 Stainless Steel Pipe Elbow

Stainless steel forged elbows are an important type of industrial pipeline fittings, mainly made of stainless steel materials. It have excellent corrosion resistance, high temperature resistance, and mechanical properties. There are various types of stainless steel forged fittings, mainly used for connecting and transmitting fluids or gas media, and widely used in multiple industries such as petroleum, chemical, power, pharmaceuticals, and food.

ASME B16.11 is a production standard for forged fittings, which includes fittings with socket and threaded connections. It specifies requirements for material, size, shape, pressure rating, tolerance range, etc. to ensure their safety and reliability in the industrial field. Stainless steel forged pipe fittings require multiple processes, including material selection, forging, heat treatment, mechanical processing, and inspection. According to the Connection Method: Socket Weld and Threaded Elbows.

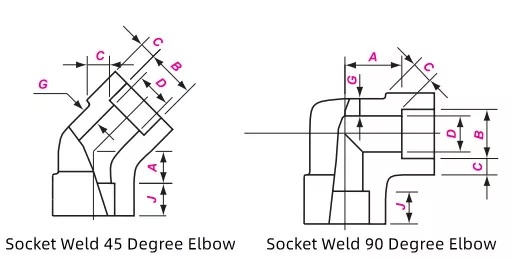

Socket Weld Elbow

Stainless steel socket weld elbows are made of stainless steel material and have excellent corrosion resistance and high temperature resistance. They are widely used in various industries, especially in chemical, metallurgical, power, shipbuilding and other fields.

Specification

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Type | 90 Degree and 45 Degree |

| Shape | Straight and Reducing Elbow |

Dimension

| DN | NPS | B | D | C | G min | Jmin | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°ELBOW | 45°ELBOW | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – | 8 | 8 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – | 8 | 8 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 13.5 | – | 8 | 11 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 |

| 32 | 1 ¼ | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 |

| 40 | 1 ½ | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 |

| 65 | 2 ½ | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – | 28.5 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.30 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – | 32.0 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – | 41.0 | – | – |

Dimension of socket weld elbow is wide, usually divided according to the nominal diameter inch. Common specifications include 1/8 inch to 4 inch. The pressure rating of stainless steel socket weld elbow is also diverse, commonly including 3000LB, 6000LB, 9000LB, or divided into SCH80, XS,SCH160, XXS, etc. The selection of pressure level needs to be determined based on the pressure requirements of the pipeline system.

| Joint Type | Class | Grade of Pipe Thickness |

| SW | 3000 | Sch80、XS |

| 6000 | Sch160 | |

| 9000 | XXS |

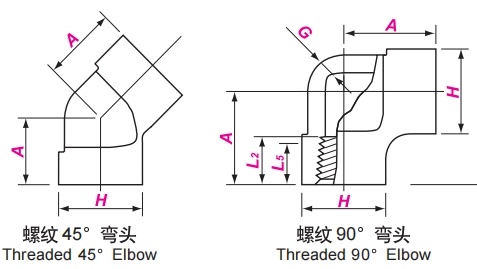

Stainless Steel Threaded Forged Elbow

Stainless steel threaded elbow can be divided into 45 degree and 90 degree elbows according to the angle. The production of stainless steel threaded elbows also needs to follow international production standards, such as ASME B16.11, BS 3799 etc., to ensure that the quality and performance of the products meet the requirements.

We are specialized in supplying stainless steel threaded elbow in three pressure ratings: class 2000,Class 3000 and 6000 at reasonable price in various sizes as per requirement.

Size: 1/8″ to 4″ / DN 6 to 100

Pressure: Class 2000, 3000, 6000

Thread Type: BSPP, BSPT, PT, NPT, MPT

Product: NPT Threaded Elbow, Tee, Coupling, Union, Bushing, Nipple, Plug.

Dimension

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||

| DN | NPS | A | H | G min | L 5 min | L 2 min | |||||

| 90°Elbows | 45°Elbows | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

Weight List

| NOMINAL SIZE | 90 DEGREE THREADED ELBOW | 45 DEGREE THREADED ELBOW | |||||

| DN | NPS | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.08 | 0.10 | 0.18 | 0.08 | 0.08 | 0.14 |

| 8 | 1/4 | 0.08 | 0.15 | 0.33 | 0.08 | 0.12 | 0.27 |

| 10 | 3/8 | 0.13 | 0.30 | 0.48 | 0.11 | 0.26 | 0.49 |

| 15 | 1/2 | 0.22 | 0.45 | 0.72 | 0.23 | 0.42 | 0.69 |

| 20 | 3/4 | 0.32 | 0.70 | 1.29 | 0.29 | 0.59 | 1.12 |

| 25 | 1 | 0.50 | 1.21 | 1.65 | 0.43 | 0.96 | 1.47 |

| 32 | 1-1/4 | 0.80 | 1.47 | 2.70 | 0.67 | 1.15 | 2.65 |

| 40 | 1-1/2 | 0.93 | 2.60 | 3.90 | 0.82 | 2.02 | 3.60 |

| 50 | 2 | 1.60 | 3.05 | 6.05 | 1.32 | 2.50 | 4.60 |

| 65 | 2-1/2 | 2.95 | 5.80 | 9.88 | 3.30 | 3.81 | 7.81 |

| 80 | 3 | 5.6 | 8.85 | 16.4 | 5.4 | 6.3 | 13.1 |

| 100 | 4 | 10.5 | 14.9 | 23.5 | 9.00 | 9.80 | 17.0 |

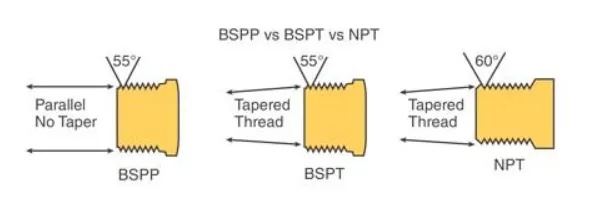

Common Thread Types of Threaded Elbow

BSPP: British Standard Pipe Parallel

BSPT: British Standard Pipe Tapered

NPT: American National Standard Pipe Tpaer

Advantages of ASME B16.11 Threaded Fitting Connections

Quick installation

Suitable for low-pressure applications, leakage integrity is good

Installation is easy, Special installation skill is not required

Less force is required for joining

Parts can be detached

Economic and cheaper

Application of Stainless Steel Pipe Elbow

Pipeline System

Petroleum and Chemical Industry

Fire Protection System

Chemical Industry

Food Processing Industry