90 Degree Stainless Steel Elbow

90 Degree Stainless Steel Elbow is a common type of pipe fittings, and common connection methods include butt welding, thread, and socket weld. We manufacture according to ASME B16.9 and B16.11 standards. ASTM A403 and ASTM A182 stainless steel elbow is a commonly used elbow in the petroleum and natural gas industry.

ZIZI ENGINGEERING CO LTD is a manufacturer supplies various of butt weld fittings. We have supplied our butt weld fittings to major customers which business in Oil & Gas, Chemical & Petrochemical, Water treatment, Nuclear & Power Plant, Offshore platform & Shipbuilding. Our products are applicable for any kinds of severe operating condition such as high pressure and high temperature or cryogenic condition.

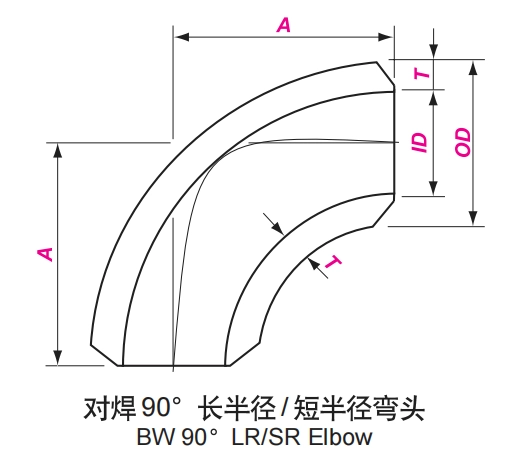

SS Butt Weld Elbow 90 Degree

SS butt weld elbow is made of stainless steel as raw material, which is formed by hot pressing. It have certain pressure resistance and can maintain a stable connection state in high-pressure environments.

90 degree stainless steel elbow is widely used in various industrial fields due to their excellent material, corrosion resistance, high temperature resistance, high strength, easy cleaning and maintenance, and other advantages.

Classified by Bending Radius

90 degree butt weld elbow can be divided into long radius and short radius according to different bending radius.

ASME B16.9 Stainless Steel Elbow Specification

The American standard ANSI/ASME B16.9 elbow, in layman’s terms, refers to an elbow produced according to the American standards. ANSI is the American national standard, and ASME is the American Society of Mechanical Engineers standard. ASME standards and ANSI standards cover the vast majority of industrial fields, including materials, processing, processes, experiments, and more. ASME cites many ANSI standards.

Stainless steel butt weld elbows produced according to ASME B16.9 have a wide range of sizes ranging 1/2 “to 48”. Common wall thickness pressure levels include Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, etc. Among them, the most commonly used are STD and XS.

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

Dimension

| Nominal size | Outside Diameter at Bevel | Center to End | ||

| 90° Elbows | ||||

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | – |

| 20 | 3/4 | 26.7 | 38 | – |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 400 | 16 | 406.4 | 610 | 406 |

| 450 | 18 | 457.0 | 686 | 457 |

| 500 | 20 | 508.0 | 762 | 508 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1448 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | ||

The stainless steel butt weld elbow produced by ZIZI Engineering Co Ltd comply with the ASTM A403 material standard.

ASME B16.11 90 Degree Stainless Steel Elbow

ASME B16.11 is a production standard for forged fittings, which includes fittings with socket and threaded connections. It specifies requirements for material, size, shape, pressure rating, tolerance range, etc. to ensure their safety and reliability in the industrial field.

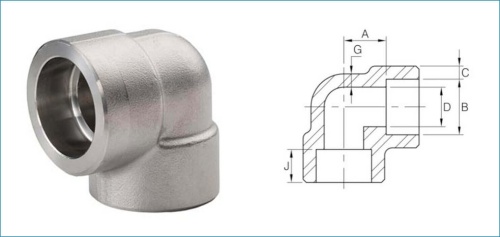

Socket Weld Elbow

Stainless steel socket weld elbows are made of stainless steel material and have excellent corrosion resistance and high temperature resistance. They are widely used in various industries, especially in chemical, metallurgical, power, shipbuilding and other fields.

Specification

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Type | 90 Degree and 45 Degree |

| Shape | Straight and Reducing Elbow |

Dimension

Dimension of socket weld elbow is wide, usually divided according to the nominal diameter inch. Common specifications include 1/8 inch to 4 inch. The pressure rating of stainless steel socket weld elbow is also diverse, commonly including 3000LB, 6000LB, 9000LB, or divided into SCH80, XS,SCH160, XXS, etc. The selection of pressure level needs to be determined based on the pressure requirements of the pipeline system.

| Joint Type | Class | Grade of Pipe Thickness |

| SW | 3000 | Sch80、XS |

| 6000 | Sch160 | |

| 9000 | XXS |

The manufacturing and inspection of stainless steel socket elbows need to follow certain standards, such as GB/T14383, ASME B16.11, MSS SP-75, JIS2316, SH3410, HG/T21634, etc. These standards specify the requirements for the size, material, performance, and other aspects of elbows.

Dimension of ASME B16.11 Socket Weld Elbow

| DN | NPS | B | D | C | G min | Jmin | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°ELBOW | 45°ELBOW | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – | 8 | 8 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – | 8 | 8 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 13.5 | – | 8 | 11 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 |

| 32 | 1 ¼ | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 |

| 40 | 1 ½ | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 |

| 65 | 2 ½ | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – | 28.5 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.30 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – | 32.0 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – | 41.0 | – | – |

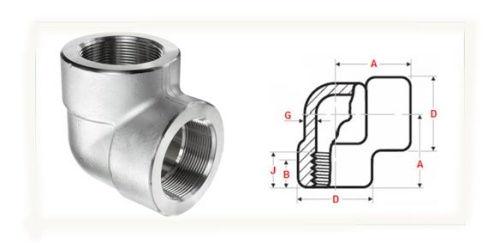

Stainless Steel Threaded Forged Elbow

Stainless steel threaded elbow shape is usually 45 degrees, 90 degrees. The production of stainless steel threaded elbows also needs to follow international production standards, such as GB/T14383, ASME B16.11, etc., to ensure that the quality and performance of the products meet the requirements.

We are specialized in supplying stainless steel threaded elbow in three pressure ratings: class 2000,Class 3000 and 6000 at reasonable price in various sizes as per requirement.

Size: 1/8″ to 4″ / DN 6 to 100

Pressure: Class 2000, 3000, 6000

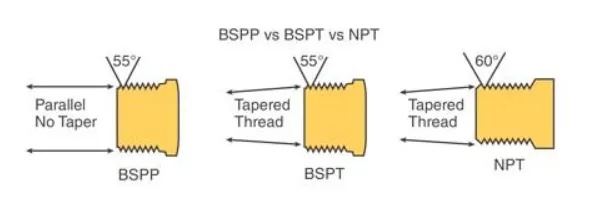

Thread Type: BSPP, BSPT, PT, NPT, MPT

Product: NPT Threaded Elbow, Tee, Coupling, Union, Bushing, Nipple, Plug.

Dimension

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||

| DN | NPS | A | H | G min | L 5 min | L 2 min | |||||

| 90°Elbows | 45°Elbows | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

Weight List

| NOMINAL SIZE | 90 DEGREE THREADED ELBOW | 45 DEGREE THREADED ELBOW | |||||

| DN | NPS | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.08 | 0.10 | 0.18 | 0.08 | 0.08 | 0.14 |

| 8 | 1/4 | 0.08 | 0.15 | 0.33 | 0.08 | 0.12 | 0.27 |

| 10 | 3/8 | 0.13 | 0.30 | 0.48 | 0.11 | 0.26 | 0.49 |

| 15 | 1/2 | 0.22 | 0.45 | 0.72 | 0.23 | 0.42 | 0.69 |

| 20 | 3/4 | 0.32 | 0.70 | 1.29 | 0.29 | 0.59 | 1.12 |

| 25 | 1 | 0.50 | 1.21 | 1.65 | 0.43 | 0.96 | 1.47 |

| 32 | 1-1/4 | 0.80 | 1.47 | 2.70 | 0.67 | 1.15 | 2.65 |

| 40 | 1-1/2 | 0.93 | 2.60 | 3.90 | 0.82 | 2.02 | 3.60 |

| 50 | 2 | 1.60 | 3.05 | 6.05 | 1.32 | 2.50 | 4.60 |

| 65 | 2-1/2 | 2.95 | 5.80 | 9.88 | 3.30 | 3.81 | 7.81 |

| 80 | 3 | 5.6 | 8.85 | 16.4 | 5.4 | 6.3 | 13.1 |

| 100 | 4 | 10.5 | 14.9 | 23.5 | 9.00 | 9.80 | 17.0 |

Common Thread Types of Threaded Elbow

BSPP: British Standard Pipe Parallel

BSPT: British Standard Pipe Tapered

NPT: American National Standard Pipe Tpaer

Application of Stainless Steel Elbow

Pipeline System

Petroleum and Chemical Industry

Fire Protection System

Chemical Industry

Food Processing Industry