One new client from Morocco send me a inquiry about hot rolled pickled and oiled steel pipe.

We marked the weight and prices for client, and quoted to him. I also attached the data sheet and sample MTC for him reference.The client feedback that our quotation is professional and thanks for the data sheet and sample MTC which is helpful to win the order.

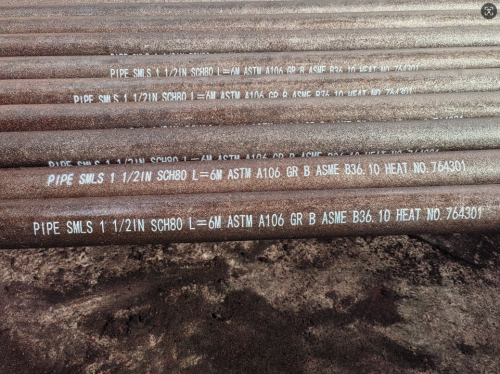

This customer requests that ASTM A106 GRB carbon steel pipe need to be pickling and oil. Actually, carbon steel pipe usually is painted to rust protection which is better than oiled. So I rechecked this thing with client. After checked with end user, the client confirm the pickling and oil for the carbon steel pipes.

Purchase Order List

| ITEM | DESCRIPTION | SIZE | MATERIAL | QTY | UNIT |

| 1 | PICKLED, OILED AND PLUGGED SEAMLESS PIPE ASME B36.10 CS SCH 80 | 1.1/2″ | ASTM A106 GR B | 2000 | M |

| 2 | PICKLED, OILED AND PLUGGED SEAMLESS PIPE ASME B36.10 CS SCH 80 | 3/4″ | ASTM A106 GR B | 600 | M |

| 3 | PICKLED, OILED AND PLUGGED SEAMLESS PIPE ASME B36.10 CS SCH 80 | 1/2″ | ASTM A106 GR B | 1500 | M |

| 4 | PICKLED, OILED AND PLUGGED SEAMLESS PIPE ASME B36.10 CS SCH 80 | 1.1/4″ | ASTM A106 GR B | 360 | M |

| 5 | PICKLED, OILED AND PLUGGED SEAMLESS PIPE ASME B36.10 CS SCH 80 | 1″ | ASTM A106 GR B | 2500 | M |

What is Hot Rolled Pickled and Oiled Steel Pipe

Hot rolled pickled and oiled steel pipe or HRPO steel pipe is undergoes a pickling and oiling process after being hot rolled. Pickling process removes scale and rust from the steel’s surface. The oiling process applies will prevent rust from forming in the future.

The pickling process is a procedure where hot rolled steel is run through a highly acidic cleaner, called pickling liquor, to remove impurities from the material.To remedy this problem, the pickled steel is immediately oiled to prevent oxidation.

Specification of Carbon Steel Pipe

Carbon steel pipe is prevalent and common used material in many industries to reliable safety, durability, structural stability and reasonable budget.

| Processing Method | Seamless and Welded |

| Size Range | 1/8″- 48″ / DN6 – 1200 |

| Thickness Schedule | SCH 10, SCH 20, SCH 40, STD, XS, SCH 100, SCH 120, SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10M |

| Surface Treatment | Blasting and Painting , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A106B / A53, API 5L B / X42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 6 |

Features of ASTM A106 GRB Carbon Steel Pipe

ASTM A106 Grade B Carbon Steel Seamless Pipes are Medium Carbon Steel Pipes with 0.3 % carbon content with combination of 0.29-1.06 % manganese. These Pipes are most commonly used for general purpose applications worldwide. ASTM A106 Grade B Pipes are ductile and strong Pipes with long wearing properties.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

| ASTM A106GRB | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.035 | 0.035 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A106 GRB | 415 min | 240 min | 22 min |

Carbon Steel Pipe Delivery

Delivery port

Shanghai, Tianjin, Qingdao

Shipment

LCL, 20GP, 40GP, Air, Courier

Packing

Bundles

Wooden box

Crates

As customer’s requirements

Certificate

CE, ISO, TEST REPORT, Stamp mill test certificate

Application of Pickled and Oiled Steel Pipe

Water supply systems

Constructions

Power plant

Pulp industry

Structural pipe