ZIZI Engineering is a leading of SMO 254 pipe fittings supplier and exporter. SMO 254 Pipe Fittings exhibits very good chloride resistance, hence, it is suitable for use in marine equipment as it can be exposed to it for longer periods without suffering from crevice corrosion.

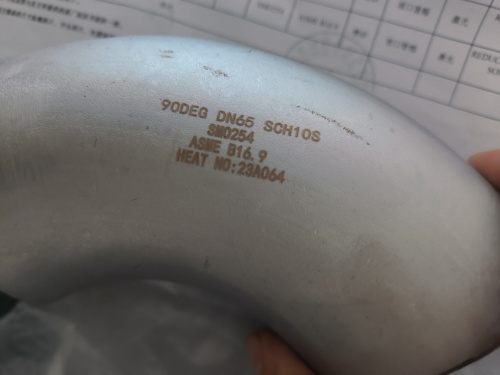

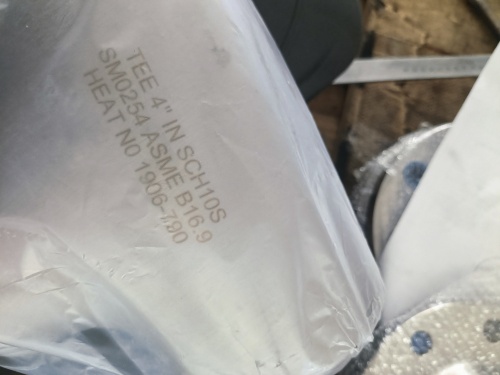

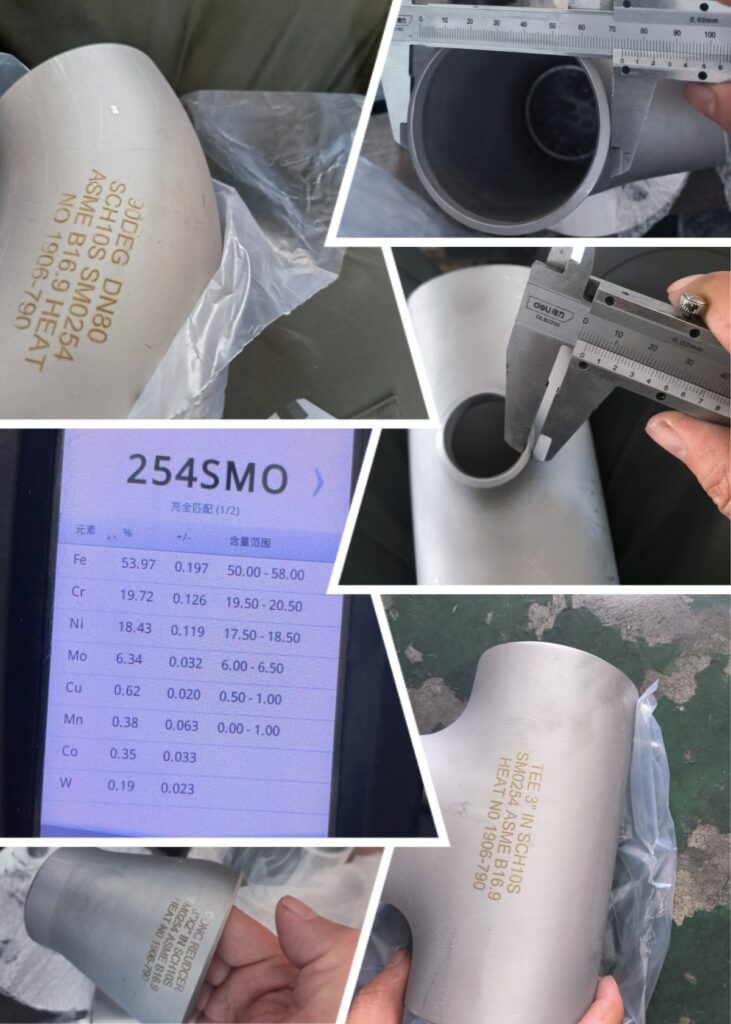

We supply these SMO 254 Pipe Fittings in various forms like tee, cross, reducers, stub ends, caps, nipples, elbow, etc. In October, we received an order for SMO 254 pipe fittings from a regular customer in China. In order to ensure the safety of transportation, we have specially customized wooden box packaging for our customers, and they were very satisfied after receiving the goods.

Purchase Order List

| ITEM | DESCRIPTION | QTY | UNIT |

| 1 | ELBOW,90°,LONG RADIUS ,BUTT WELD,SEAMLES SIZE : DN65 / 2 1/2 INCH, SCH 10S MOC : SMO 254 | 120 | EA |

| 2 | REDUCER CONCENTRIC,BUTT WELD,SEAMLESS SIZE : 4″ X 3″, SCH 10S MOC : SMO 254 | 76 | EA |

| 3 | REDUCER CONCENTRIC,BUTT WELD,SEAMLESS SIZE : 3″ X 2 1/2″, SCH 10S MOC : SMO 254 | 110 | EA |

| 4 | PIPE 254SMO DN65 (2 1/2″) SCH 10S,SEAMLESS 1 LENGTH : 6 METERS SIZE : DN65 (2 1/2″), SCH 10S MOC : SMO 254 | 68 | EA |

| 5 | TEE,EQUAL,BW,SEAMLESS,SMO254,2.5″,SCH10S | 200 | EA |

| 6 | REDUCER.CON.BWSMLS,SMO254.3X2″SCH10S | 200 | EA |

| 7 | TEE EQUAL,BUTT WELD,SEAMLESS SIZE : 3″ x 3″, SCH 10S MATERIAL : SMO 254 | 56 | EA |

| 8 | ELBOW,90°,LONG RADIUS ,BUTT WELD,SEAMLES SIZE : DN100 / 4 INCH, SCH 10S MOC : SMO 254 | 37 | EA |

| 9 | TEE,EQUAL,BW,SEAMLESS,SMO254,4″,SCH10S | 63 | EA |

| 10 | TEE,REDUCER,BW,SMLS,SMO254,3″X1″,SCH10S | 52 | EA |

| 11 | ELBOW,90°,LONG RADIUS ,BUTT WELD,SEAMLES SIZE : DN80 / 3 INCH, SCH 10S MOC : SMO 254 | 90 | EA |

Specification of A403 UNS S31254 Butt Weld Pipe Fittings

| Specifications | ASTM A403 / ASME SA403 |

| Size | Seamless Butt Weld Fittings : 1/2″ – 10″ Welded Butt Weld Fittings : 1/2″ – 48″ |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

Types of ASME B16.9 SMO 254 Butt Weld Fittings

There are various types of SMO 254 butt weld pipe fittings that can meet the design requirements of various pipeline systems. The common types of stainless steel butt weld fittings include butt weld elbow, tee, concentric reducer, eccentric reducer, cross, cap, stub end, etc. These fittings play important roles in different pipeline systems.

We supply all kinds of Alloy 254 SMO Butt Weld Pipe Fittings for use in various high corrosion applications.

How to Inspect of Stainless Steel Butt weld Pipe Fittings

Our quality inspectors will complete the product quality inspection work before delivery. Usually, we measure the diameter and wall thickness of the welded pipe fittings, and use a PMI to check whether the materials are correct.We conduct these quality checks to make sure that the pipe fittings are free from errors and ideal for use in various climatic conditions.

The tests conducted to make sure the highest standards include mill test, raw material test, hardness test, 100% radiography, macro test, intergranular corrosion test, chemical analysis, third party inspection, and Positive Material Identification testing.

Features of SMO 254 Material

SMO 254 pipe fittings are resistant to bromides, fluorides and chlorides. They have high ductility and high strength. The minimum tensile strength is 650MPa and the minimum yield strength is 300MPa.

Chemical Composition of SMO 254 Pipe Fittings

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | Cu |

| SMO 254(UNS S31254) | MIN | 17.50 | 19.50 | 6.00 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| SMO 254(UNS S31254) | 650 min | 300 min | 35 min | 50 min |

Equivalent Grades A403 UNS S31254 Butt weld Fittings

| STANDARD | AFNOR | WERKSTOFF NR. | UNS | SIS | EN |

| SMO 254 | Z1 CNDU 20.18.06Az | 1.4547 | S31254 | 2378 | X1CrNiMoCuN20-18-7 |

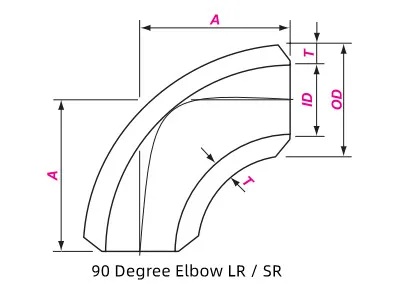

Dimension of 1.4547 90 Degree Elbow Fittings

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1-1/4 | 42.2 | 48 | 32 |

| 40 | 1-1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2-1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3-1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1447 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

| 1300 | 52 | 1321.0 | 1981 | 1321 |

| 1400 | 56 | 1422.0 | 2134 | 1422 |

| 1500 | 60 | 1524.0 | 2286 | 1524 |

| 1600 | 64 | 1626.0 | 2438 | 1626 |

| 1700 | 68 | 1727.0 | 2591 | 1727 |

| 1800 | 72 | 1829.0 | 2743 | 1829 |

| 1900 | 76 | 1930.0 | 2896 | 1930 |

| 2000 | 80 | 2032.0 | 3048 | 2032 |