ZIZI ENGEERING CO LTD specialize in producing SS 904L pipe fittings. Stainless Steel 904L is a high-end austenitic stainless steel with low carbon content, containing nickel, copper and molybdenum. It offers superior corrosion resistance when compared to conventional chromium-nickel steels such as 316L and 304L.

Recently we have received an order from a regular customer regarding SS 904L pipe fittings. The purchased products include ASTM A403-N08904/SS-904L 90deg elbow,equal tee,reducing tee and concentric reducer.

| ELBOW 90°, BW, DN200 Sch 10S, ASTM A403-N08904/SS-904L, ERW, ASME B 16.9 | 300 Ea |

| ELBOW 90°, BW, DN50 Sch 10S, ASTM A403-N08904/SS-904L, ERW, ASME B 16.9 | 80 Ea |

| EQUAL TEE, BW, DN200 Sch 10S, ASTM A403-N08904/SS-904L,ERW, ASME B 16.9 | 76 Ea |

| EQUAL TEE°, BW, DN50 Sch 10S, ASTM A403-N08904/SS-904L,ERW, ASME B 16.9 | 200 Ea |

| REDUCING TEE, BW, DN200X80 Sch 10S, ASTM A403-N08904/SS-904L, ERW ASME B 16.9 | 58 Ea |

| CONCENTRIC REDUCER, BW, DN80X50 Sch 10S, ASTM A403-N08904/SS-904L, ASME B 16.9 | 210 Ea |

Advantages of SS 904L Pipe Fittings Material

SS 904L pipe fittings are widely used due to their remarkable corrosion resistance. SS 904L is a high-alloy stainless steel with high chromium, nickel, and molybdenum levels. It is more resistant to corrosion than other types of stainless steel. This metal is highly resistant to pitting and crevice corrosion, making it ideal for use in harsh environments.

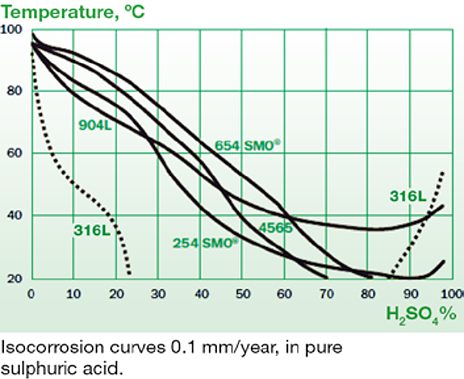

The high content of alloying elements in 904L gives the alloy exceptionally good resistance to uniform corrosion.

Product Features

Corrosion resistant

Accurate dimensions

Can sustain high pressure & temperature load

Rust proof finish

Smooth transition from flange thickness to pipe

Ensure excellent stress distribution

Chemical Composition of ASTM A403-N08904 Butt Weld Fittings

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| SS 904L (N08904) | MIN | 23.00 | 19.00 | 4.00 | 1.00 | ||||||

| MAX | 0.02 | 2.00 | 0.040 | 0.030 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| SS 904L (N08904) | 490 min | 215 min | 35 min |

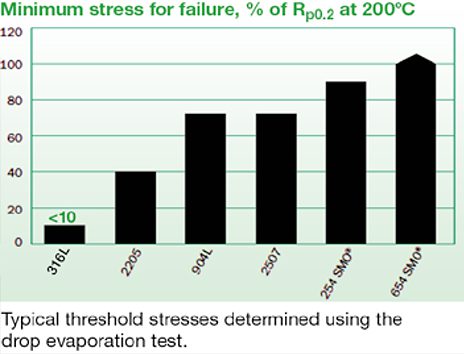

SS 904L was originally developed to withstand environments containing dilute sulfuric acid, and is one of the few stainless steels that, at temperatures up to 95°F (35°C), provides full resistance in such environments within the entire concentration range of 0 to 100%. Therefore, the higher performance austenitic stainless steels such as 904L have very good resistance to SSC.

What is the difference between SS 316L and SS 904L?

Stainless steel 904L material has a wide range of applications, including marine and offshore structures, chemical processing, and processing industries. SS 904L is more resistant to general and localized corrosion than traditional stainless steels such as SS 304L and SS 316L. SS 904L is highly resistant to chloride pitting and crevice corrosion. It has high resistance to chloride pitting and crevice corrosion.

Corrosion Resistance

Perhaps the most important feature of any alloy used in marine applications is its ability to handle constant exposure to corrosive substances. The content of alloying elements such as chromium (Cr), molybdenum (Mo), and nitrogen (N) in stainless steel materials is used to determine their corrosion resistance. In this case, the content of these elements in SS904L stainless steel is significantly higher than that in 316L, so SS 904L is more likely to withstand the corrosive force of seawater.

Steel Hardness

To further understand the differences between 904L and 316L stainless steel, we must examine the hardness of both metals. The best way to do this is to look at the Rockwell Scale, which measures the indentation hardness of a material.

Both 904L and 316L stainless steel have a Rockwell hardness value below 95, which is typical for most stainless steel. However, it is far more important that seawater filter screens withstand the internal dangers like chloride and other corrosion attacks. 904L offers greater protection overall, which sets it above 316L.

Cost

If we only look at the price, SS316L should be more chosen. Because of its wide application, convenient procurement, and low price. The cost of SS904L is higher than 316L, but the enhanced corrosion resistance of 904L stainless steel makes it less likely to wear and break due to corrosion, thus requiring less maintenance during its service life.

Inspection of ASTM A403 N08904 Butt Weld Fittings

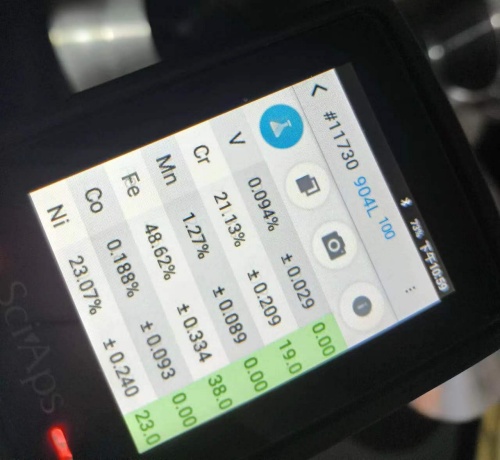

We have professional quality inspectors responsible for product weight testing. Usually, we measure the diameter and wall thickness of the welded pipe fittings, and use a PMI to check whether the materials are correct.

Inspection of Pipe Fittings Marking

Inspection of SS 904L Pipe Fittings Size

PMI Inspection

ASTM A403 N08904 Butt Weld Fittings Supplier

We can supply a variety of standard butt welded pipe fittings, such as UNS, JIS, BS, GOST, EN, AISI SS 904L fittings, DIN SS 1.4539 fittings, SS WP904L fittings, SS UNS N08904 butt welded pipe fittings, etc.

ZIZI ENGEERING CO LTD is a top supplier and exporter of 904L stainless steel butt welded pipe fittings, which have excellent acid resistance at the lowest temperature and concentration. In addition, compared to previous alloys, it greatly improves structural stability, thereby reducing concerns during welding, manufacturing, and maintenance processes.

SS 904L butt weld fittings also have high resistance to pitting corrosion in chloride solutions, and have high resistance to cracks and stress corrosion cracking. Due to the high degree of alloying between nickel and molybdenum, the performance of ASTM A403 N08904 alloy fittings is superior to other austenitic stainless steels. SS 904L fittings are non-magnetic under all conditions and have excellent formability and weldability. The austenitic structure also gives stainless steel 904L fittings excellent toughness, even at low temperatures. Due to all the advantages of using 904L stainless steel fittings, it can be found in many applications in various key industries.

The general corrosiveness of SS 904L reducer fittings is lower than that of SS 904, and they can resist a range of corrosive media. SS 904L tee fittings are used in places where intergranular corrosion resistance is required, as well as in places where parts are continuously heated or cooled within the range of 800 to 1500 degrees Fahrenheit.

Grade SS 904L Butt weld Pipe Fittings Classes

| CR | Corrosion-resistant grade. S through WU Classes does not apply. |

|---|---|

| WP-S | Seamless |

| WP-W | Welded, UT or RT all pipes starting material welds made with the filler metal. All 904L pipe fittings manufacturer welds except as excluded in A/SA403 paragraph 5.4.3. If UT is substituted for RT, all welds must be examined 100% for their length as required by A/SA403 paragraph 5.6 |

| WP-WX | RT all welds with or without filler metal. |

| WP-WU | UT all welds with a filler or without filler metal. |

| WP GR CLASS | Insert grades (904L) and class (S,W,WX, or WU). Applies to fittings meeting all physical and chemical requirements of both grades. |

Stainless Steel ASTM A403 WP904L Fittings Manufacturing Standards

| ASTM A403/A403M | Wrought Austenitic SS Piping Fittings |

|---|---|

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

| BS3799 | Specification for pipe fittings, Socket-welding and threaded/screwed fitting for the petroleum industry |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic SS Piping Fitting |

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.28 | Wrought Steel SR Elbows and Butt weld Returns |

| API 590-605 ASME B16.9 | Factory-Made Wrought Butt-welding Fittings |

UNS N08904 Buttweld Fittings Equivalent Grade Chart

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | X1NiCrMoCu25-20-5 | 1.4539 | – | – | SUS 904L |

ASME B16.9 Butt Weld Fittings Specification

Specification of ASME B16.9

Standard: ANSI/ASME B16.9, B16.28, MSS-SP-43

Specification: ASTM / ASME A403 / SA403

Size: NPS 1/2″ to 48″

Thickness: Sch 10S to Sch XXS

Type: Seamless & Welded Butt weld Fittings

Types of Stainless Steel Pipe Fittings

There are various types of SS 904L butt weld pipe fittings that can meet the design requirements of various pipeline systems. The common types of butt weld fittings include stainless steel 904L butt weld elbow, tee, concentric reducer, eccentric reducer, cross, cap, stub end, etc. These fittings play important roles in different pipeline systems.

| SS 316L 90 Degree Elbow | 45 Degree Elbow |

| Concentric Reducer | SS 904L Eccentric Reducer |

| SS 904L Equal Tee | Reducing Tee |

| SS 304L 5D Bend | 3D Bend |

| Long Stub End | Short Stub End |

| SS 316L Cross | Steel Cap |

Application of SS 904L Pipe Fittings

SS 904L butt weld pipe fittings are widely used in multiple fields due to their excellent corrosion resistance and high strength.

Petrochemical Industry

Nuclear Power

Mechanical

Medical Equipment