ASTM seamless pipe is a type of steel pipe with a hollow cross-section and no welds. It is made of materials such as carbon steel, alloy steel or stainless steel. ASTM seamless pipes have the advantages of strong pressure bearing capacity, stable quality, good corrosion resistance and strong mechanical properties. So they are widely used in petroleum, chemical, shipbuilding, nuclear power and machinery manufacturing industries.

Specification of ASTM Seamless Pipe

The standard used for ASTM seamlelss pipes is ASME B36.10M or ASME B16.19M. The size range from 1/8 inch to 48 inche. There are also various specifications for wall thickness, such as SCH40, STD, XS, SCH80, SCH160, XXS, etc. Different wall thickness specifications are suitable for different application environments and pressure requirements.

| Processing Method | Seamless and Welded |

| Size Range | 1/8″-48″ /DN6-1200 |

| Thickness Schedule | SCH 10,SCH 20,SCH 40,STD,XS,SCH 100,SCH 120,SCH 160,XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10M |

| Surface Treatment | Blasting and Painting,Epoxy Powder FBE,2PE,3PE Coating |

| Material Grade | ASTMA106B/A53,API5LB/X42/46/52/56/60/65/70,A333 GR6 |

Weight List of ASTM Seamless Pipe

| Nominal Size | OD | kg/m | |||||||||||||

| DN | NPS | mm | Sch 10 | Sch 20 | Sch 30 | STD | Sch 40 | Sch 60 | XS | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXS |

| 6 | 1/8 | 10.3 | 0.28 | 0.32 | 0.37 | 0.37 | 0.47 | 0.47 | |||||||

| 8 | 1/4 | 13.7 | 0.49 | 0.54 | 0.63 | 63 | 0.8 | 0.8 | |||||||

| 10 | 3/8 | 17.1 | 0.83 | 0.7 | 0.84 | 0.84 | 1.1 | 1.1 | |||||||

| 15 | 1/2 | 21.3 | 1 | 1.12 | 1.27 | 1.27 | 1.62 | 1.62 |  | 1.95 | 2.55 | ||||

| 20 | 3/4 | 26.7 | 1.28 | 1.44 | 1.69 | 1.69 | 2.2 | 2.2 | 1.9 | 364 | |||||

| 25 | 1 | 33.4 | 2.09 | 2.18 | 2.5 | 2.5 | 3.24 | 3.24 | 4.24 | 5.45 | |||||

| 32 | 1 1/4 | 42.2 | 2.7 | 287 | 3.39 | 3.39 | 4.47 | 4.47 |    | 5.16 | 7.77 | ||||

| 40 | 1 1/2 | 48.3 | 3.11 | 3.53 | 4.05 | 4.05 | 5.41 | 5.41 | 7.25 | 9.58 | |||||

| 50 | 2 | 60.3 | 3.03 | 4.48 | 5.44 | 5.44 | 7.48 | 7.48 | 11.11 | 13.44 | |||||

| 65 | 2 1/2 | 73 | 5.26 | 8.04 | 8.63 | 863 | 11,41 | 11.41 | 14.92 | 20.39 | |||||

| 80 | 3 | 88.9 | 6.45 | 9.92 | 11.29 | 1.29 | 15.72 | 15.72 | 21.35 | 27.68 | |||||

| 90 | 3 1/2 | 101.6 | 7.4 | 1.41 | 13.57 | 13.57 | 18.63 | 18.63 | |||||||

| 100 | 4 | 114.3 | 8.38 | 12.91 | 18.07 | 16.07 | 22.32 | 22.32 | 28.32 |    | 33.54 | 41.03 | |||

| 125 | 5 | 141.3 | 11.57 | 21.77 | 21.77 | 30.97 | 30.87 | 40.28 | 40.11 | 57.43 | |||||

| 150 | 6 | 168.3 | 13.48 | 28.26 | 28.26 | 42.58 | 42.56 | 5420 | 67.58 | 79.22 | |||||

| 200 | 8 | 219.1 | 19.98 | 33.31 | 36.81 | 42.55 | 42.55 | 53.08 | 84.64 | 84.84 | 75.92 | 90.44 | 100.9 | 11.3 | 107.9 |

| 250 | 10 | 273 | 27.78 | 41.77 | 51.03 | 60.31 | 60.31 | 81.55 | 81.55 | 96.01 | 114 | 133.1 | 155.2 | 172.3 | 155.2 |

| 300 | 12 | 323.9 | 36 | 49.72 | 85.2 | 73.88 | 79.73 | 109 | 97.48 | 32.1 | 159.9 | 87 | 208.1 | 238 | 187 |

| 350 | 14 | 355.6 | 54.69 | 67.9 | 81.33 | 81.33 | 94.55 | 126.7 | 107.4 | 58.1 | 195 | 224.7 | 253.6 | 281.7 |    |

| 400 | 16 | 406.4 | 62.64 | 77.83 | 93.27 | 93.27 | 123.3 | 160.1 | 123.3 | 209.5 | 2456 | 206.7 | 333.2 | 365.4 | |

| 450 | 18 | 457 | 70.57 | 37.71 | 122.4 | 105.2 | 155.8 | 205.7 | 139.2 | 254.6 | 4098 | 363.8 | 408.3 | 459.4 | |

| 500 | 20 | 508 | 78.55 | 117.2 | 155.1 | 117.2 | 183.4 | 247.8 | 155.1 | 311.2 | 381.5 | 441.5 | 508.1 | 564.8 | |

| 550 | 22 | 559 | 86.54 | 129.1 | 171.1 | 129.1 | – | 294.2 | 171.1 | 373.8 | 451.4 | 527 | 611 | 672.2 | |

| 600 | 24 | 610 | 94.53 | 141.1 | 209.6 | 141.1 | 255.4 | 355.3 | 187.1 | 442.1 | 547.7 | 640 | 720.2 | 808.2 | |

Material Standards for Seamless Pipe

ASTM seamless pipe materials include carbon steel; low-temperature steel; pipeline steel; alloy steel; stainless steel and duplex stainless steel.

Carbon Steel

Carbon steel is one of the main materials for ASTM seamless pipe. It is mainly composed of iron and carbon, and may contain small amounts of elements such as manganese, phosphorus, etc. Carbon steel has excellent mechanical and processing properties and is widely used in various industrial fields.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Cu | Ni | Cr | Mo | V | Si |

| ASTM A106B | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.035 | 0.04 | 0.40 | 0.400 | 0.40 | 0.15 | 0.080 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A106 GR B | 415 min | 240 min | 22 min |

Low-Temperature Steel

Low temperature seamless pipe is a steel pipe material with excellent performance in low-temperature environments. It must meet the -46 ℃ impact requirement. Widely used in various fields such as petroleum, chemical, natural gas, electricity, aviation, and shipbuilding. It can maintain stability in strength and hardness at extremely low temperatures, ensuring the normal operation of pipelines and equipment.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | Nb |

| ASTM A333 GR 6 | MIN | 0.29 | 0.10 | |||||||||

| MAX | 0.30 | 1.06 | 0.025 | 0.025 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 | 0.02 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A333 GR 6 | 415 min | 240 min | 30 min |

API 5L Seamless Pipe

API 5L seamless pipe has become an important material for long-distance fluid transportation pipelines due to its high strength, high toughness, good weldability, and corrosion resistance.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | V | Ni | Mo | Cu |

| API 5L X42 | MIN | |||||||||

| MAX | 0.160 | 1.650 | 0.02 | 0.01 | 0.450 | 0.07 | ||||

| API 5L X65 | MIN | |||||||||

| MAX | 0.12 | 1.60 | 0.025 | 0.015 | 0.450 | 0.50 | 0.50 | |||

| API 5L X70 | MIN | |||||||||

| MAX | 0.12 | 1.7 | 0.025 | 0.015 | 0.45 | 0.5 | 0.5 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) |

| API 5L X42 | 415min | 290min |

| API 5L X65 | 535min | 450min |

| API 5L X70 | 570min | 485min |

Alloy Steel

Alloy steel is made on the basis of carbon steel by adding one or more alloying elements such as chromium, nickel, molybdenum, silicon, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A335 P5 | MIN | 0.30 | 4.0 | 0.44 | ||||

| MAX | 0.15 | 0.60 | 0.025 | 0.025 | 0.50 | 6.0 | 0.65 | |

| ASTM A335 P9 | MIN | 0.30 | 0.25 | 8.0 | 0.9 | |||

| MAX | 0.15 | 0.60 | 0.025 | 0.025 | 1.00 | 10.0 | 1.1 | |

| ASTM A335 P11 | MIN | 0.05 | 0.30 | 0.50 | 1.00 | 0.44 | ||

| MAX | 0.15 | 0.60 | 0.025 | 0.025 | 1.00 | 1.50 | 0.65 | |

| ASTM A335 P22 | MIN | 0.05 | 0.30 | 1.90 | 0.87 | |||

| MAX | 0.15 | 0.60 | 0.025 | 0.025 | 0.50 | 2.60 | 1.13 |

Mechanical Properties

| MATERIAL | ASTM A335 P5 | ASTM A335 P9 | ASTM A335 P11 | ASTM A335 P22 |

| T.S (MPA) | 415 min | 415 min | 415 min | 415 min |

| Y.S (MPA) | 205 min | 205 min | 205 min | 205 min |

| EL % | 30 min | 30 min | 30 min | 30 min |

Stainless Steel Seamless Pipe

Stainless steel is an alloy steel with corrosion resistance, mainly composed of elements such as iron, chromium, nickel, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A312 TP304L | MIN | 8.00 | 18.00 | |||||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | |||

| ASTM A312 TP316L | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | ||

| ASTM A312 TP317L | MIN | 11.00 | 18.00 | 3.00 | ||||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 15.00 | 20.00 | 4.00 | ||

| ASTM A312 TP321 | MIN | 9.00 | 17.00 | |||||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 | 0.10 | ||

| ASTM A312 TP347 | MIN | 9.00 | 17.00 | |||||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 19.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A312 TP304L | 485 min | 170 min | 35 min |

| ASTM A312 TP316L | 485 min | 170 min | 35 min |

| ASTM A312 TP317L | 515 min | 205 min | 35 min |

| ASTM A312 TP321 | 515 min | 205 min | 35 min |

| ASTM A312 TP347 | 515 min | 205 min | 35 min |

Duplex Stainless Steel Seamless Pipe

Duplex stainless steel seamless steel pipes have excellent resistance to comprehensive corrosion and localized corrosion, good weldability and processability.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A790 UNS S32205 | MIN | 4.50 | 22.00 | 3.00 | 0.14 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A790 UNS S32750 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 | |

| ASTM A790 S32760 | MIN | 24.00 | 3.00 | ||||||||

| MAX | 0.03 | 1.00 | 0.03 | 26.00 | 4.00 | ||||||

| ASTM A790 S31803 | MIN | 4.5 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 6.5 | 23.00 | 3.50 | 0.20 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A790 UNS S32205 | 655min | 450min | 25min | 290max |

| ASTM A790 UNS S32750 | 800min | 550min | 15min | 300max |

| ASTM A790 S32760 | 750min | 550min | 25min | 310max |

| ASTM A790 S31803 | 620min | 450min | 25min | 290max |

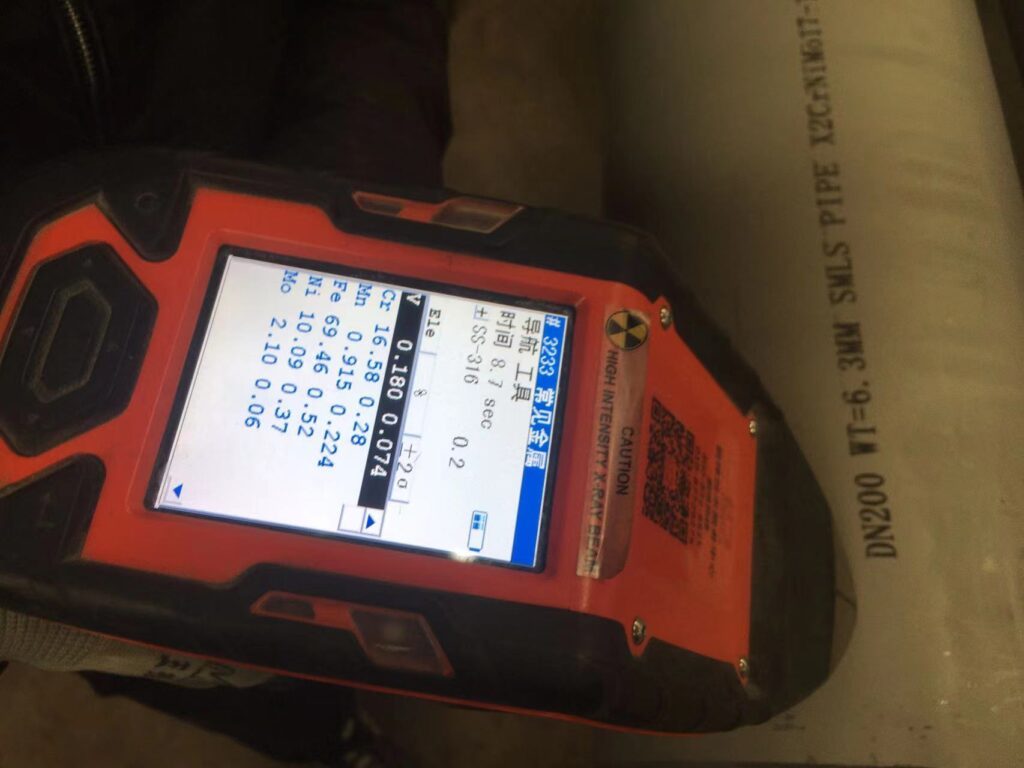

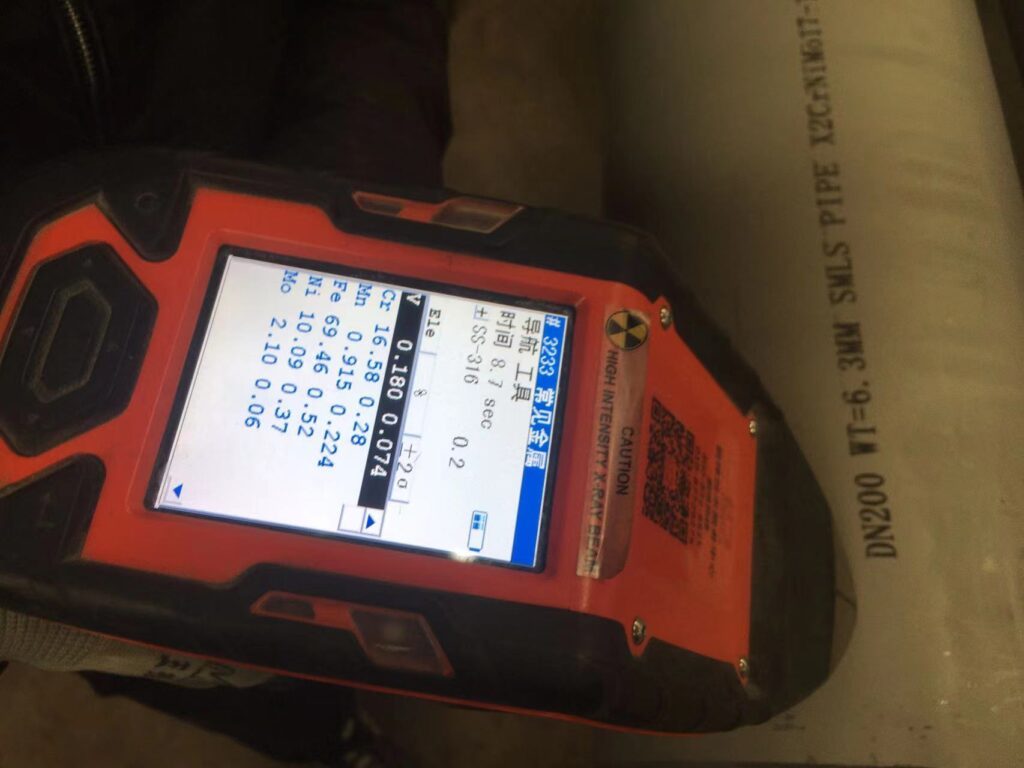

How to Inspect ASTM Seamless Pipe

Package of Seamless Pipe

ASTM seamless pipes require surface treatment before packaging. Carbon steel pipes are generally coated with anti rust paint or galvanized to protect their surface and prevent rusting. Stainless steel pipes undergo acid pickling and sandblasting treatment on the surface to ensure a clean and tidy appearance.

ASTM seamless pipes are often packaged by bundling them together. Bundled steel pipes should be firmly tied with steel strips or wires to ensure that they will not loosen during transportation. Sealing and labeling should be applied before packaging, and the labels should be clear and legible.