Stainless steel socket weld coupling, as a very important type of pipe fitting in pipeline connections. They are widely used in high-pressure pipeline systems below 4 inches.

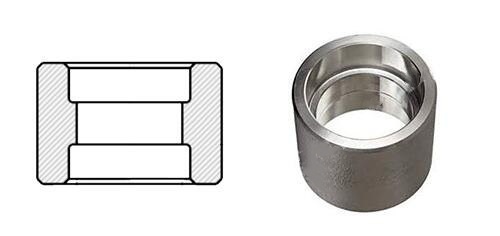

Socket weld coupling are pipe connectors machined by forging round steel or steel ingots, using socket welding connection method, that is, steel pipes are inserted into socket holes for welding. The main standards followed in its manufacturing include ANSI/ASME B16.11 and GB/T 14383-2008.

Stainless steel socket weld coupling is a forged pipe fitting that connects pipes through socket welding. It has the advantages of reasonable structure, easy operation, and wide applicability. In the field of pipeline engineering, socket clamps play an important connecting role, ensuring the stability and safety of pipeline systems.

Specification of Socket Weld Coupling

| Type | Elbow, Tee, Cross, Coupling, Cap, Lateral |

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F321, F310S, F317, F347, F904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

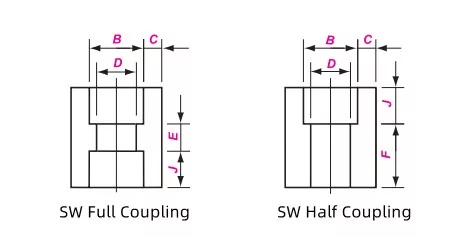

Dimension of Stainless Steel Socket Weld Coupling

DN | NPS | B | D | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.30 | 4.60 | 4.01 | – | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.50 | 5.03 | 4.37 | – | – |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.30 | – | – | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – |

Weight Chart (KG)

| DN | NPS | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.05 | 0.06 | – |

| 8 | 1/4 | 0.06 | 0.07 | – |

| 10 | 3/8 | 0.08 | 0.10 | – |

| 15 | 1/2 | 0.13 | 0.16 | 0.29 |

| 20 | 3/4 | 0.20 | 0.28 | 0.47 |

| 25 | 1 | 0.28 | 0.48 | 0.68 |

| 32 | 1-1/4 | 0.48 | 0.65 | 1.08 |

| 40 | 1-1/2 | 0.52 | 0.94 | 1.12 |

| 50 | 2 | 0.95 | 1.65 | 1.95 |

| 65 | 2-1/2 | 1.52 | – | – |

| 80 | 3 | 1.75 | – | – |

| 100 | 4 | 2.8 | – | – |

Types of Stainless Steel Socket Weld Coupling

There are various types of stainless steel socket weld coupling, which can be classified into multiple types according to different classification standards.

Having two socket ends, it can simultaneously connect two pipes or fittings, increasing the stability and strength of the connection.

Only has one socket end for connecting a single pipe or fitting.

Socket weld full coupling can be divided into equal and reducing coupling. Socket weld equal and reducing coupling each have their unique uses and advantages in pipeline connections. The equal coupling is suitable for connecting pipes of the same diameter and has the characteristics of easy installation and good sealing. Reducing coupling can connect pipes of different diameters, achieving flexible connection of pipeline systems and effective changes in fluid characteristics. When choosing, comprehensive consideration should be given to specific engineering requirements and the characteristics of the pipeline system.

Socket Weld Coupling VS Threaded Coupling

Socket Weld Coupling

Features: By connecting pipes or fittings through socket welding, it has high connection strength and sealing performance.

Application: Widely used in various pipeline connection scenarios that require high strength and sealing. Mainly suitable for smaller pipe diameters and lower pressures.

Connection method: The socket coupling is a connection method that inserts the tail of the pipeline into the sleeve, similar to a socket, and uses rolling or heating to make the connection between the pipeline and the sleeve more secure.

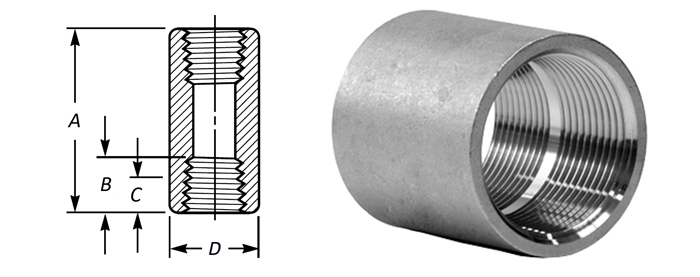

Threaded Coupling

Features: Connecting pipes or fittings through threads without welding, easy to install and disassemble.

Application: Suitable for scenarios where connection strength and sealing performance are not high requirements.

Connection method: Threaded coupling is connected to the pipeline through a threaded form.

Advantage

Stainless steel socket weld coupling have the advantages of easy installation, safety and stability, good sealing, corrosion resistance, and high temperature resistance, and are widely used in industries.

Compact structure and firm connection

Easy installation and high efficiency

Strong adaptability and wide application range

Good sealing performance

Good corrosion resistance

Easy maintenance

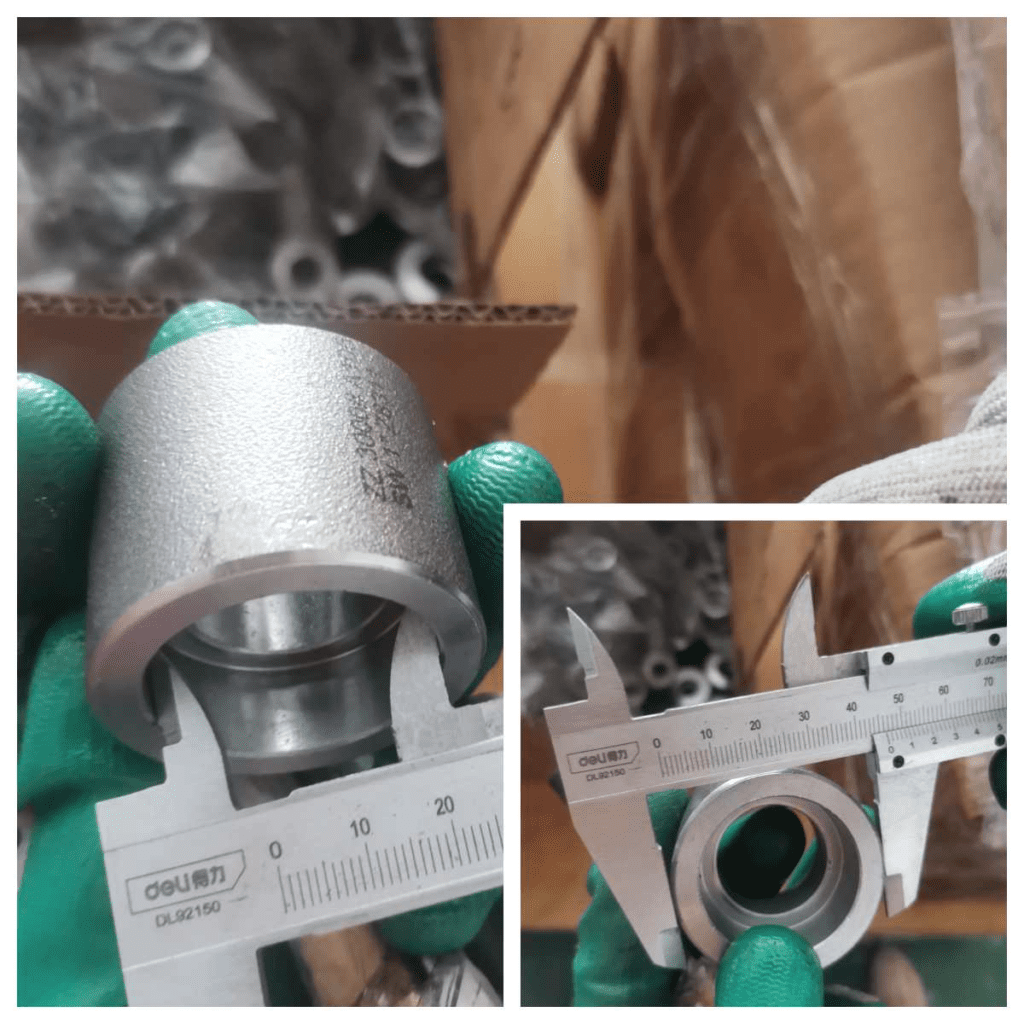

How to Inspect Stainless Steel Socket Weld Coupling

Visual the surface of socket weld coupling body.

Measure dimensions that large end diameter, small end diameter, wall thickness of outlets.

Check the marking of 1″ Class 3000 ASTM A182 F316 ASME B16.11 ZB311