Stainless steel socket weld elbow is an important pipe fitting. It formed by molding and forging blanks from round steel or steel ingots, and then processed by lathe machine.

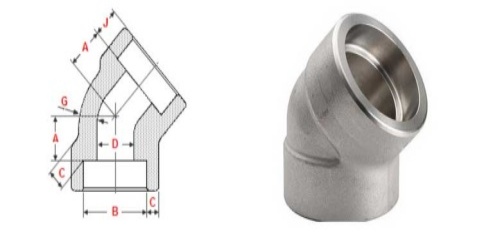

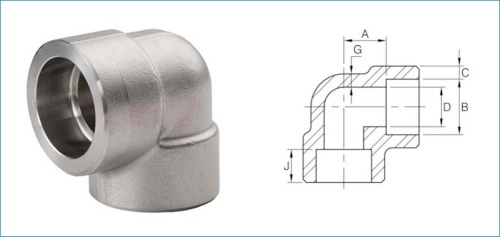

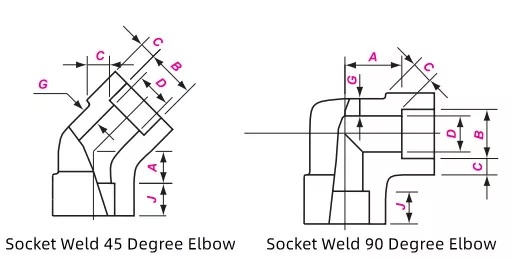

According to the angle, it can be divided into 45 degree and 90 degree socket elbow. It can meet the needs of different pipelines.

Stainless steel socket weld elbows are made of stainless steel material and have excellent corrosion resistance and high temperature resistance. They are widely used in various industries, especially in chemical, metallurgical, power, shipbuilding and other fields.

Specification of Socket Weld Elbow

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Type | 90 Degree and 45 Degree |

| Shape | Straight and Reducing Elbow |

Dimension

Dimension of socket weld elbow is wide, usually divided according to the nominal diameter inch. Common specifications include 1/8 inch to 4 inch. Customization can also be made according to customer needs. The pressure rating of stainless steel socket weld elbow is also diverse, commonly including 3000LB, 6000LB, 9000LB, or divided into SCH80, XS,SCH160, XXS, etc. The selection of pressure level needs to be determined based on the pressure requirements of the pipeline system.

| Joint Type | Class | Grade of Pipe Thickness |

| SW | 3000 | Sch80、XS |

| 6000 | Sch160 | |

| 9000 | XXS |

The manufacturing and inspection of stainless steel socket elbows need to follow certain standards, such as GB/T14383, ASME B16.11, MSS SP-75, JIS2316, SH3410, HG/T21634, etc. These standards specify the requirements for the size, material, performance, and other aspects of elbows.

Dimenson of ASME B16.11 Stainless Steel Socket Weld Elbow

| DN | NPS | B | D | C | Gmin | Jmin | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°ELBOW | 45°ELBOW | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – | 8 | 8 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – | 8 | 8 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 13.5 | – | 8 | 11 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 |

| 32 | 1 ¼ | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 |

| 40 | 1 ½ | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 |

| 65 | 2 ½ | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – | 28.5 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.30 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – | 32.0 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – | 41.0 | – | – |

Material Features of Stainless Steel Socket Weld Elbow

Stainless steel socket weld elbows are made of stainless steel material, which has excellent corrosion resistance, high temperature resistance, and good mechanical properties. Common stainless steel grades include ASTM A182 F304,F316,F44,F51,F53 etc., which can meet the needs of different working conditions.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

Due to the use of high-strength materials such as forged steel or stainless steel, stainless steel socket weld elbow can withstand high pressure. Its pressure rating can reach 3000LB, 6000LB or even higher, suitable for high-pressure pipeline systems. The plug-in connection method makes the installation of stainless steel socket elbows more convenient and efficient.hether transporting corrosive media or high-temperature and high-pressure media, suitable stainless steel socket elbows can be found to meet the requirements.

Inspection of Stainless Steel Socket Weld Elbow

The inspection of stainless steel socket weld elbow is a comprehensive and meticulous process aimed at ensuring that their quality, performance, and safety meet relevant standards and requirements.

Material Testing

Chemical Composition Analysis

Mechanical Performance Testing

Metallographic Examination

Appearance Inspection

Surface Quality

Dimensional Inspection

Non Destructive Testing

X-Ray Inspection

Ultrasonic Examination

Magnetic Testing

The testing of stainless steel socket elbows is a multi-faceted and multi-level process that requires the comprehensive use of multiple testing methods and means to ensure that their quality, performance, and safety meet relevant standards and requirements.