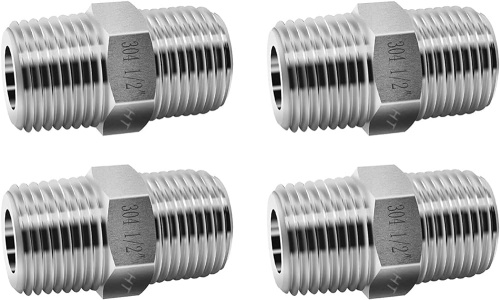

Stainless steel hex nipple is a special type of pipe fitting. It has a hexagonal structure, which gives it high strength. The male thread design can be easily connected to pipelines or equipment. Ensuring the tightness and stability,thereby preventing fluid or gas leakage. Therefore, hex nipples are often used in industrial pipelines and precision instruments. Hex nipples are generally produced according to GB/T 14383 and ASME 16.11 production standards, as well as BS3799 standards.

Specification of Stainless Steel Hex Nipple

| Types | Equal and Reducing Hex Nipple |

| Thread | NPT, PT, BSPP, BSPT, PF |

| Stardard | ASME B16.11 / BS3799 / EN10241 |

| Size Range | 1/8″,1/4″, 1/2″, 3/4″, 1″, 1-1/4″, 1-1/2″, 2″, 2-1/2″, 3″ |

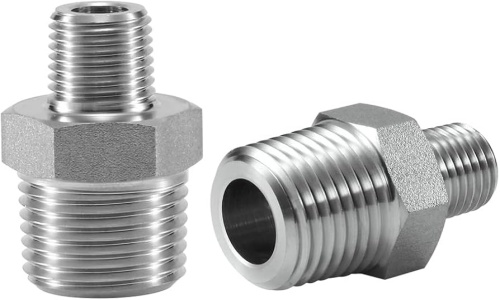

Stainless steel hex nipple is a commonly usein pipeline connections, with various characteristics and a wide range of application scenarios. Common types of hex nipple include equal hex nipple and reducing hex nipple, which can meet the needs of different pipeline designs.

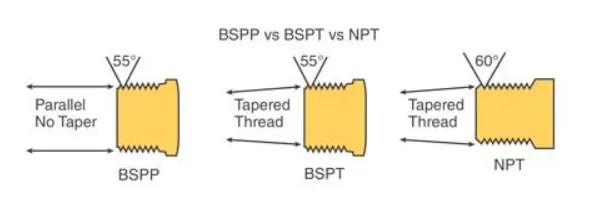

How to Determine Pipe Thread Type

Usually, we use caliper to measure the first, fourth and final full thread. If the measurements are all the same, then it’s parallel. If the measurements decrease in size, then it’s tapered. NPT, NPTF, BSPT, and Metric Tapered are examples of tapered threads.

Common Thread Types of Stainless Steel Hex Nipple

BSPP: British Standard Pipe Parallel

BSPT: British Standard Pipe Tapered

NPT: American National Standard Pipe Tpaer

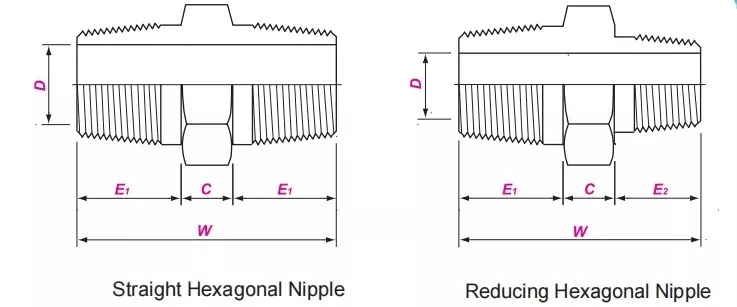

Dimension of ASME B16.11

ASME B16.11 hex nipple have hexagon shaped section in the middle and male thread on both ends to associate two other pipes or fittings. There are different types such as A105 hex nipple or stainless steel hex nipple.

Stainless Steel Hex Nipple Dimension List

| DN | NPS | C nom | E 1nom | E 2 nom | W | D | |

| Sch80 | Sch160 | ||||||

| 6 | 1/8 | 6 | 10 | – | 26 | 5 | 4 |

| 8 | 1/4 | 6 | 15 | – | 36 | 7 | 6 |

| 8×6 | 1/4×1/8 | 6 | 15 | 10 | 31 | 5 | 4 |

| 10 | 3/8 | 8 | 16 | – | 40 | 10 | 8 |

| 10×8 | 3/8×1/4 | 8 | 16 | 15 | 39 | 7 | 6 |

| 15 | 1/2 | 8 | 20 | – | 48 | 13 | 10 |

| 15×10 | 1/2×3/8 | 8 | 20 | 16 | 44 | 10 | 8 |

| 15×8 | 1/2×1/4 | 8 | 20 | 15 | 43 | 7 | 6 |

| 20 | 3/4 | 10 | 21 | – | 52 | 18 | 14 |

| 20×15 | 3/4×1/2 | 10 | 21 | 20 | 51 | 13 | 10 |

| 20×10 | 3/4×3/8 | 10 | 21 | 16 | 47 | 10 | 8 |

| 25 | 1 | 10 | 25 | – | 60 | 23 | 19 |

| 25×20 | 1×3/4 | 10 | 25 | 21 | 56 | 18 | 14 |

| 25×15 | 1×1/2 | 10 | 25 | 20 | 55 | 13 | 10 |

| 32 | 1-1/4 | 12 | 25 | – | 62 | 31 | 28 |

| 32×25 | 1-1/4 × 1 | 12 | 25 | 25 | 62 | 23 | 19 |

| 32×20 | 1-1/4×3/4 | 12 | 25 | 21 | 58 | 18 | 14 |

| 32×15 | 1-1/4×1/2 | 12 | 25 | 20 | 57 | 13 | 10 |

| 40 | 1-1/2 | 16 | 26 | – | 68 | 36 | 32 |

| 40×32 | 1-1/2 x 1-1/4 | 16 | 26 | 25 | 67 | 31 | 28 |

| 40×25 | 1-1/2 x 1 | 16 | 26 | 25 | 67 | 23 | 19 |

| 40×20 | 1-1/2 x 3/4 | 16 | 26 | 21 | 63 | 18 | 14 |

| 40×15 | 1-1/2×1/2 | 16 | 26 | 20 | 62 | 13 | 10 |

| 50 | 2 | 18 | 27 | – | 72 | 47 | 40 |

| 50×40 | 2×1-1/2 | 18 | 27 | 26 | 71 | 36 | 32 |

| 50×32 | 2×1-1/4 | 18 | 27 | 25 | 70 | 31 | 28 |

| 50×25 | 2×1 | 18 | 27 | 25 | 70 | 23 | 19 |

| 50×20 | 2×3/4 | 18 | 27 | 21 | 66 | 18 | 14 |

| 50×15 | 2×1/2 | 18 | 27 | 20 | 65 | 13 | 10 |

| 65 | 2-1/2 | 20 | 38 | – | 96 | 57 | 51 |

| 65×50 | 2-1/2×2 | 20 | 38 | 27 | 85 | 47 | 40 |

| 65×40 | 2-1/2×1-1/2 | 20 | 38 | 26 | 84 | 36 | 32 |

| 65×32 | 2-1/2×1-1/4 | 20 | 38 | 25 | 83 | 31 | 28 |

| 65×25 | 2-1/2×1 | 20 | 38 | 25 | 83 | 23 | 19 |

| 65×20 | 2-1/2×3/4 | 20 | 38 | 21 | 79 | 18 | 14 |

| 80 | 3 | 20 | 40 | – | 100 | 70 | 63 |

| 80×65 | 3×2-1/2 | 20 | 40 | 38 | 98 | 57 | 51 |

| 80×50 | 3×2 | 20 | 40 | 27 | 87 | 47 | 40 |

| 80×40 | 3×1-1/2 | 20 | 40 | 26 | 86 | 36 | 32 |

| 80×32 | 3×1-1/4 | 20 | 40 | 25 | 85 | 31 | 28 |

| 80×25 | 3×1 | 20 | 40 | 25 | 85 | 23 | 19 |

Weight List(KG)

| DN | NPS | SCH 80 | SCH 160 |

| 6 | 1/8 | 0.02 | 0.03 |

| 8 | 1/4 | 0.03 | 0.04 |

| 10 | 3/8 | 0.05 | 0.06 |

| 15 | 1/2 | 0.10 | 0.12 |

| 20 | 3/4 | 0.13 | 0.17 |

| 25 | 1 | 0.22 | 0.29 |

| 32 | 1-1/4 | 0.34 | 0.41 |

| 40 | 1-1/2 | 0.47 | 0.58 |

| 50 | 2 | 0.69 | 0.91 |

| 65 | 2-1/2 | 1.35 | 1.69 |

| 80 | 3 | 2.03 | 2.59 |

Features of Stainless Steel Material

Stainless steel material has excellent corrosion resistance and wear resistance. It can maintain good performance in various harsh environments. Common stainless steel materials include ASTM A182 F304, F316,F44,F51,F55 etc., which have good corrosion resistance, high temperature resistance, and high toughness.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

Stainless steel hex nipple is often used in industrial pipelines to connect various pipelines and equipment. Its high strength and torsional resistance enable it to maintain good performance even under high pressure and high temperature.