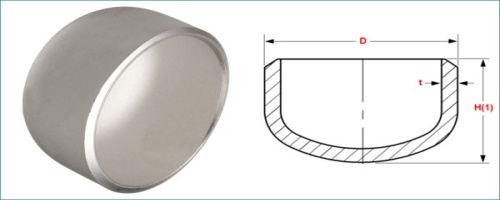

Stainless steel butt weld cap is made of stainless steel material. It fixed at the end of the pipeline by welding to seal the pipeline. Its function is the same as that of a pipe plug. As an important pipeline connection accessory, it plays an important role in multiple fields.

Specification of Stainless Steel Butt Weld Cap

| Size | 1/2” – 48” / DN15 – 1200 |

| Thickness | SCH 10 – SCH 160, XXS |

| Dimensions | ANSI / ASME B16.9 / MSS SP 43/JIS B2311/2312/2313/DIN2605/2615/2616/EN10253 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Standard

There are various production standards for butt weld cap internationally. ASME B16.9 is a standard developed by the American Society of Mechanical Engineers (ASME) . It specifies requirements for the size, material, pressure rating, marking, and inspection of welded pipe components.

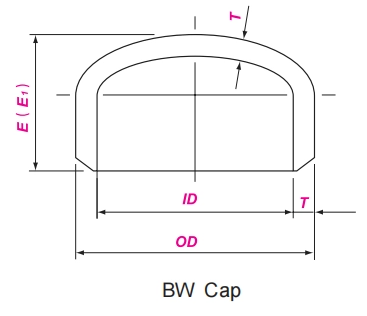

Dimension of ASME B16.9 Stainless Steel Butt Weld Cap

| DN | NPS | OD | E | E1 |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 11/4 | 42.2 | 38 | 38 |

| 40 | 11/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 21/2 | 73.0 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 31/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273.0 | 127 | 152 |

| 300 | 12 | 323.8 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457.0 | 203 | 229 |

| 500 | 20 | 508.0 | 229 | 254 |

| 550 | 22 | 559.0 | 254 | 254 |

| 600 | 24 | 610.0 | 267 | 305 |

| 650 | 26 | 660.0 | 267 | — |

| 700 | 28 | 711.0 | 267 | — |

| 750 | 30 | 762.0 | 267 | — |

| 800 | 32 | 813.0 | 267 | — |

| 850 | 34 | 864.0 | 267 | — |

| 900 | 36 | 914.0 | 267 | — |

| 950 | 38 | 965.0 | 305 | — |

| 1000 | 40 | 1016.0 | 305 | — |

| 1050 | 42 | 1067.0 | 305 | — |

| 1100 | 44 | 1118.0 | 343 | — |

| 1150 | 46 | 1168.0 | 343 | — |

| 1200 | 48 | 1219.0 | 343 | — |

ASTM A403 Butt Weld Cap

ASTM A403 is the material standard for stainless steel butt weld cap, commonly used stainless steel materials include WP304/316/904L/31254/321, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | |||

| ASTM A403 WP904L | MIN | 23.00 | 19.00 | 4.00 | 1.00 | ||||||

| MAX | 0.02 | 2.00 | 0.045 | 0.035 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 | |

| ASTM A403 WP31254 | MIN | 17.50 | 19.50 | 6.00 | 0.18 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 0.25 | 1.0 | |

| ASTM A403 WP321 | MIN | 9.00 | 17.00 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 | ASTM A403 WP904L | ASTM A403 WP31254 | ASTM A403 WP321 |

| T.S (MPA) | 515 min | 515 min | 490 min | 650-820 | 515 min |

| Y.S (MPA) | 205 min | 205 min | 220 min | 300 min | 205 min |

| EL % | 28 min | 28 min | 28 min | 28 min | 28 min |

Structural Characteristics of Butt Weld cap

Diversified shape design

Sturdy welded structure

Good sealing performance

Good corrosion resistance

High standard size specifications

Strict manufacturing and testing processes

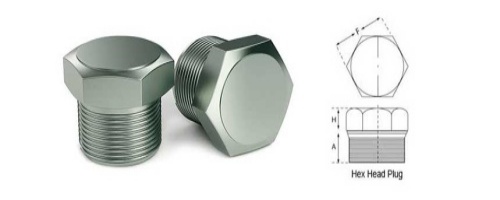

Difference Between Stainless Steel Butt Weld Cap and Plug

Although stainless steel butt weld cap and plugs are sealing components in pipeline systems. They have significant differences in structure, use, and installation methods.

There are significant differences in the structure, purpose, and installation method between stainless steel butt weld caps and plugs. Butt weld caps are more suitable for situations that require high strength and good sealing. But plugs are more suitable for situations that require quick installation or disassembly. When selecting, appropriate components should be selected based on specific usage environments and requirements.

Application

Stainless steel butt weld cap is widely used in multiple fields due to their excellent corrosion resistance and high strength.

Petrochemical Industry

Nuclear Power

Mechanical

Medical Equipment