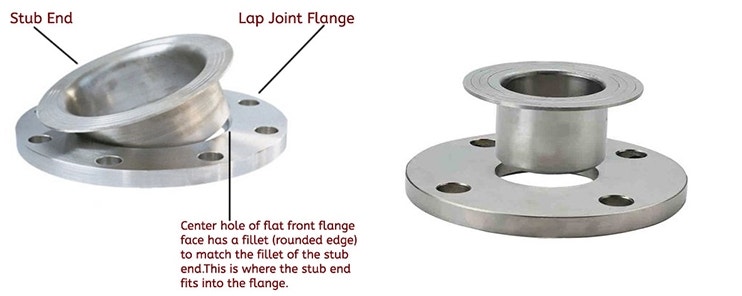

Stainless steel stub end is a type of butt welded pipe fittings. It usually used in conjunction with lap joint flange to achieve flange connection in pipeline systems. The stub end section is generally formed by stamping technology. It’s divided into long and short stub end according to the length of the straight pipe end. The selection of forming methods confirms that the product is not damaged. Some large diameter flanges still require welding technology. The production standards for stub end mainly comply with the American production standards ANSI/ASME B16.9 and MSS SP-43.

ASME B16.9 stainless steel stub end can be divided into long and short stub ends based on their length.

| Type | Long Pattern (LP) and Short Pattern (SP) |

| Size Range | 1/2” – 24” / DN15 – 600 |

| Thickness Schedule | SCH10S/SCH40S/SCH80S |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Material Standard for Stainless Steel Stub End

Stainless steel stub ends are produced using high-quality stainless steel materials. Stainless steel mainly have characteristics such as corrosion resistance, high temperature resistance, and stable performance. They are suitable for various types of pipeline systems and application environments. The common stainless steel material standard is the American standard ASTM A403. This standard includes different grades of stainless steel, such as ASTM A403 WP304/316, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 28 min | 28 min |

ASME B16.9 Specification

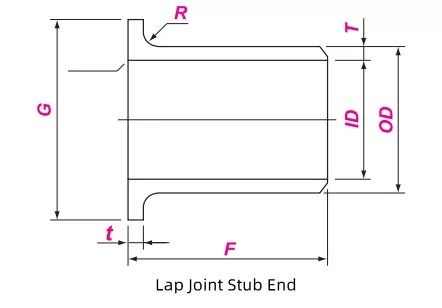

ASME B16.9 is one of the main manufacturing standards for stainless steel stub end. This standard specifies key parameters such as dimensions, tolerances, material requirements, and inspection methods for stub end. In specifications, the size range of stub end is from 1/2 “to 24”. It can meet the connection requirements of pipes with different diameters.

Dimension of ASME B16.9 Stainless Steel Stub End

| DN | NPS | OD | F | R | G | ||||

| Max. | Min. | Long Type | Short Type | A | Bmax | ||||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 | |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 | |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 | |

| 32 | 11/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 | |

| 40 | 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 | |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 | |

| 65 | 21/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 | |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 | |

| 90 | 31/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 | |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 | |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 | |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 | |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 | |

| 250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 | |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 | |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 | |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 | |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 | |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 | |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 641 | |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 | |

Stainless Steel Stub End Referenced Weight List

| Nominal Size | SCH10S | SCH40S | SCH80S | ||||

| DN | NPS | Short Pattern | Long Pattern | Short Pattern | Long Pattern | Short Pattern | Long Pattern |

| 15 | 1/2 | 0.07 | 0.09 | 0.09 | 0.12 | 0.12 | 0.16 |

| 20 | 3/4 | 0.09 | 0.12 | 0.12 | 0.16 | 0.15 | 0.21 |

| 25 | 1 | 0.15 | 0.25 | 0.18 | 0.32 | 0.24 | 0.43 |

| 32 | 1-1/4 | 0.19 | 0.34 | 0.25 | 0.43 | 0.33 | 0.57 |

| 40 | 1-1/2 | 0.22 | 0.39 | 0.31 | 0.52 | 0.43 | 0.75 |

| 50 | 2 | 0.35 | 0.71 | 0.52 | 1.02 | 0.73 | 1.49 |

| 65 | 2-1/2 | 0.46 | 0.95 | 0.81 | 1.6 | 1.1 | 2.22 |

| 80 | 3 | 0.62 | 1.22 | 1.1 | 2.11 | 1.5 | 2.98 |

| 90 | 3-1/2 | 0.7 | 1.36 | 1.52 | 2.55 | 2.09 | 3.65 |

| 100 | 4 | 0.94 | 1.59 | 1.8 | 3.05 | 2.58 | 4.44 |

| 125 | 5 | 1.3 | 2.8 | 2.25 | 5.42 | 3.6 | 7.86 |

| 150 | 6 | 1.75 | 3.3 | 3.59 | 7.02 | 5.76 | 11.3 |

| 200 | 8 | 2.9 | 4.95 | 5.98 | 10.6 | 9.18 | 16.2 |

| 250 | 10 | 4.79 | 8.5 | 10.2 | 18.4 | 13.7 | 24.9 |

| 300 | 12 | 7.2 | 10.9 | 14.9 | 22.8 | 19.5 | 30.2 |

| 350 | 14 | 7.95 | 15 | 15.8 | 28.7 | 21.6 | 38.6 |

| 400 | 16 | 9.5 | 17.3 | 18.9 | 33.1 | 25.2 | 44.5 |

| 450 | 18 | 11.1 | 19.8 | 22 | 38 | 29.3 | 51.1 |

| 500 | 20 | 14.1 | 25.9 | 24.3 | 42.3 | 32.6 | 56.8 |

| 550 | 22 | 16.5 | 28.2 | – | – | – | – |

| 600 | 24 | 19.8 | 35 | 29.6 | 51.2 | 39.7 | 68.8 |

Features and Advantages

Convenient Connection

Good Sealing Performance

Strong Adaptability

Application and Precaution

ASME B16.9 stainless steel stub end is widely used in pipeline systems in industries such as petroleum, chemical, and natural gas. Especially in situations that require frequent disassembly and maintenance, such as oil refineries, chemical plants, and natural gas transmission pipelines.

Choose the Appropriate Material

Pay Attention to Size Matching

Adhere to Manufacturing Standards

ASME B16.9 stainless steel stub end is an important type of pipeline connector, widely used in industries. Understanding its definition, classification, materials, specifications, manufacturing standards, and application precautions is of great significance for ensuring the safe operation of pipeline systems.