Carbon Steel 90 Degree Elbow

Carbon steel 90 degree elbow is a common type of pipe fittings, and common connection methods include butt welding, thread, and socket weld. We manufacture according to ASME B16.9 and B16.11 standards. ASTM A234 WPB elbow is a commonly used elbow in the petroleum and natural gas industry.

We have supplied our butt weld fittings to major customers which business in Oil & Gas, Chemical & Petrochemical, Water treatment, Nuclear & Power Plant, Offshore platform & Shipbuilding. Our products are applicable for any kinds of severe operating condition such as high pressure and high temperature or cryogenic condition.

ASTM A105 90 Degree Elbow

ASTM A105 is mainly made of carbon steel material grade, and they are used for making forged pipe fittings. Carbon Steel 90 degree elbow is used to change the direction of pipeline flow.Forged 90 degree elbow is used for pipes with smaller diameters, and they are ideal to be used in a high-temperature application in a pressure system. We manufacture ASTM A105 elbow, which is very easy to use and needs low maintenance. It is one of the main reasons behind its popularity in various industries.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

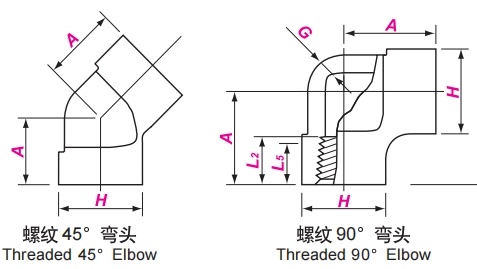

Dimension of Threaded Elbow

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||

| DN | NPS | A | H | Gmin | L 5 min | L 2 min | |||||

| 90°Elbows | 45°Elbows | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

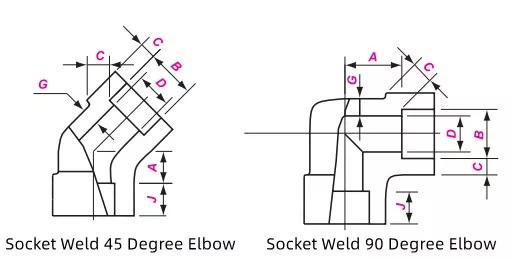

Dimension of Socket Weld Elbow

| DN | NPS | B | G | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| ave | min | ave | min | ave | min | ||||||

| 6 | 1/8 | 10.9 | 2.41 | 3.15 | 一 | 3.18 | 3.18 | 3.96 | 3.43 | 一 | 一 |

| 8 | 1/4 | 14.3 | 3.02 | 3.68 | 一 | 3.78 | 3.30 | 4.60 | 4.01 | 一 | 一 |

| 10 | 3/8 | 17.7 | 3.20 | 4.01 | 一 | 4.01 | 3.50 | 5.03 | 4.37 | 一 | 一 |

| 15 | 1/2 | 21.9 | 3.73 | 4.78 | 7.47 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 3.91 | 5.56 | 7.82 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 4.55 | 6.35 | 9.09 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 4.85 | 6.35 | 9.70 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 5.08 | 7.14 | 10.15 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 |

| 50 | 2 | 61.2 | 5.54 | 8.74 | 11.07 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 7.01 | 一 | 8.16 | 7.62 | 一 | 一 | |||

| 80 | 3 | 89.9 | 7.62 | 一 | 9.52 | 8.30 | 一 | 一 | |||

| 100 | 4 | 115.5 | 8.56 | 一 | 10.69 | 9.35 | 一 | ||||

ASTM A234 Carbon Steel 90 Degree Elbow

ASTM A234 is standard specification for wrought carbon steel & alloy steel pipe fittings which covers seamless and welded types.

The specification for the carbon steel 90 degree elbow, covers steel pipe fittings such as the carbon steel elbow A234 WPB which are primarily used in applications for the pressure piping systems. Generally these Elbow A234 Wpc fittings are designed to be used in moderate and high temperature applications . The A234 SR elbow is the standard of pipe fittings material, which indicates the materials properties of different kinds of carbon steel and alloy steel. One such steel grade in this standard is the WPB . In the term WPB, W means weldable, P stands for pressure, while B is grade b. B refers to the minimum yield strength, such as the ASTM A106/A53 Gr.B or API 5L Gr.B. A234 WPB, which is the most common material used in the manufacture of carbon steel pipe fittings.

W = WELDABLE / wrought

P = RELATED TO P NUMBER OF ALLOY MATERIAL

B = REFER TO MINIMUM YIELD OF MATERIAL

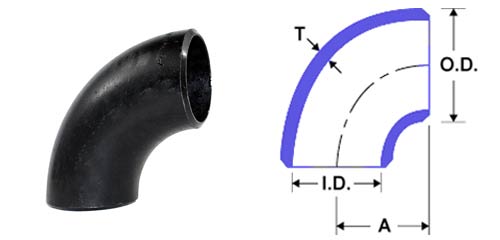

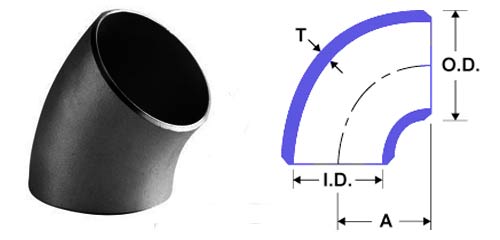

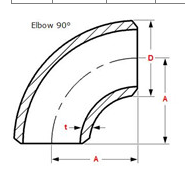

Long Radius & Short Radius Elbow

There are two main types of 90 degree elbows long radius (LR) and short radius (SR) elbows. Long-radius elbows have a longer center line radius than the pipe diameter, making them less abrupt in the change of direction. They are mainly used in low-pressure and low-velocity systems.

Long Radius Carbon Steel 90 Degree Elbow

Fittings that change direction in a piping system are called elbows which available in 90 degree long radius elbow. Both of them has the center line at 1.5 x NPS from elbow end.

Short Radius Carbon Steel 90 Degree Elbow

Short radius elbow almost same as above long radius, The difference is center line to end is 1 x NPS and available in 90 degree only.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

| ASTM A234 WPB | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A234 WPB | 415 min | 240 min | 22 min | 30 min | 197 max |

Dimension of Butt Weld Elbow

| DN | NPS | OD(MM) | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1-1/4 | 42.2 | 48 | 32 |

| 40 | 1-1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2-1/2 | 73 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3-1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559 | 838 | 559 |

| 600 | 24 | 610 | 914 | 610 |

| 650 | 26 | 660 | 991 | 660 |

| 700 | 28 | 711 | 1067 | 711 |

| 750 | 30 | 762 | 1143 | 762 |

| 800 | 32 | 813 | 1219 | 813 |

| 850 | 34 | 864 | 1295 | 864 |

| 900 | 36 | 914 | 1372 | 914 |

| 950 | 38 | 965 | 1447 | 965 |

| 1000 | 40 | 1016 | 1524 | 1016 |

| 1050 | 42 | 1067 | 1600 | 1067 |

| 1100 | 44 | 1118 | 1676 | 1118 |

| 1150 | 46 | 1168 | 1753 | 1168 |

| 1200 | 48 | 1219 | 1829 | 1219 |

| 1300 | 52 | 1321 | 1981 | 1321 |

| 1400 | 56 | 1422 | 2134 | 1422 |

| 1500 | 60 | 1524 | 2286 | 1524 |

| 1600 | 64 | 1626 | 2438 | 1626 |

Carbon steel butt weld fittings use seamless or welded pipe as starting material and process to the shape of elbows, tees & reducers by hot and cold forming.

China manufacturer supplies various of carbon steel butt weld fittings, they are 90 degree elbow, straight and reducing tee, concentric and eccentric reducer, cap, stub end. Why more and more people choose butt welding even if the operation is difficult?

Leak proof and Strong

Good Strength

Corrosion Resistance

Low Cost

Universal and Economical

Large Output

Wild Application