Blind flange is a special type of flange,it has not central hole. Stainless steel blind flange common used to seal the ports of pipelines or equipment. When it is necessary to isolate a certain section of pipeline, install the blind flange on the end of the pipeline, and tightly connect the blind flange with the pipeline flange through fasteners to achieve a sealing effect. Stainless steel blind flange has advantages such as corrosion resistance, high temperature resistance, shock resistance, and pressure resistance. It can effectively protect the normal operation of equipment and pipelines.

Function of Blind Flange

Pipeline Sealing

Equipment Maintenance

Segmented Sealing of Pipelines

Prevent Media Mixing

Stainless steel blind flange have the advantages of convenient use, economic practicality, and good sealing effect. Meanwhile, it can also be classified according to different pressure levels to meet the needs of different fluid media.

Specification of Stainless Steel Blind Flange

Stainless steel blind flange specification include American standard ASME B16.5 ASME B16.47、MSS SP-44. European standard EN1092, etc. Size range from 1/2″ to 60″ .The pressure range: Class 150 to 2500; PN6, 10, 16, 25, etc.

| Standards | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ to 48″ |

| Designation | A 182 / A 240, SA 182 / SA 240 |

| Class | 150#, 300#, 400#, 600#, 900#, 1500# & 2500#. |

| Grade | ASTM A182 F304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L ETC. |

ASME B16.5 Stainless Steel Blind Flange

ASME B16.5 is a standard for pipe flanges and flanged fittings, developed by the American Society of Mechanical Engineers (ASME). This standard specifies in detail the design, dimensions, material selection, manufacturing process, inspection methods, and marking requirements.

Feature

Material selection: Blind flanges can be made of carbon steel, stainless steel, alloy steel, etc.

Dimensions: The dimensions of blind flanges can be customized according to the needs of the pipeline system to ensure compatibility with pipes and other flange accessories.

Sealing performance: The sealing surface types of blind flange are diverse, such as raised face (RF), flat face (FF), concave convex face (MFM), etc., to meet different sealing requirements. Blind flange can achieve reliable sealing effect through bolt connection and gasket compression.

Detachability: Compared to welded heads or pipe caps, blind flanges have the ability to be disassembled, making it convenient for pipeline maintenance, expansion, or cleaning when needed.

Application : ASME B16.5 blind flange is widely used in the fields of petrochemical, natural gas industry, chemical industry, etc.

ASME B16.47 Blind Flange

ASME B16.47 is a standard for large pipe flanges and flange fittings, developed by the American Society of Mechanical Engineers. This standard in detail the requirements for the size, pressure rating, material, testing, etc. Large pipe flanges and is applicable to the connection of large pipelines in industries such as petrochemicals, power.

Feature

Size and pressure rating: Stainless steel blind flange have a wide range of sizes and pressure ratings. According to ASME B16.47 standard the range of sizes from 26″ to 60″(DN 650 to DN 1500) or larger. In ASME B16.47 standard, the pressure rating of blind flange is divided into A series and B series. A series: includes 5 levels including Class 150, 300, 400, 600, 900, etc. B-series: includes 6 levels including Class 75, 150, 300, 400, 600, 900, etc. These pressure levels represent the pressure that the flange can withstand.

Materials: Blind flanges can be made of various materials, such as carbon steel, stainless steel, alloy steel, etc. The selection of specific materials depends on the application environment, medium requirements, and design conditions.

Sealing performance: The sealing surface types of blind flange are diverse, such as raised face (RF), raised face (MFM), etc. Blind flange can achieve reliable sealing effect through bolt connection and gasket compression.

Detachability: Stainless steel blind flanges are usually connected by bolts and nuts for easy disassembly and reinstallation. This allows for easy maintenance, expansion, or cleaning of pipelines when needed.

Application : ASME B16.47 blind flange is used in the fields of petrochemical, natural gas industry, power engineering, chemical industry, etc.

ASTM A182 F304 Stainless Steel Blind Flange

ASTM A182 F304 blind flange is made of ASTM A182 F304 standard material. This type of flange does not have a central hole and is mainly used to close the end of the pipeline or to isolate a certain part of the pipeline.

ASTM A182 F304 stainless steel is a low-carbon austenitic stainless steel with excellent corrosion resistance and mechanical properties. It contains approximately 18% chromium and 8% nickel, allowing it to maintain good stability in various corrosive media.

The design and manufacturing of ASTM A182 F304 stainless steel blind flange comply with relevant standards and specifications, ensuring reliable sealing and strength under various working conditions. It has a variety of sealing surface types, such as raised face (RF), flat face (FF), concave convex face (MFM), etc., and suitable sealing surface types can be selected according to specific application requirements.

ASTM A182 F304 blind flange is widely used in the fields of petrochemicals, natural gas industry, power, chemical industry, etc., for sealing large pipeline systems or isolating certain parts of pipelines. Its detachable nature allows for easy maintenance, expansion, or cleaning of pipelines when needed.

It should be noted that when selecting and using ASTM A182 F304 blind flange, reasonable selection and design should be made based on specific application environments and requirements, and relevant installation and maintenance standards should be followed to ensure its reliability and safety.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | N |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 |

| T.S (MPA) | 515 min |

| Y.S (MPA) | 205 min |

| EL % | 30 min |

| R/A % | 50 min |

ASME B16.5 Stianless Steel Blind Flange Dimension and Weight

CLASS 150 Dimension and Weight List

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

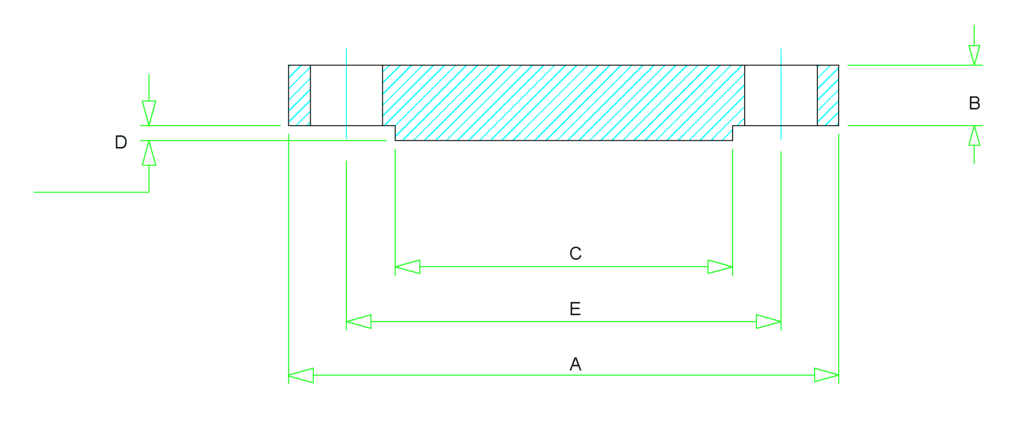

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

CLASS 300 Dimension and Weight List

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 95 | 12.7 | 34.9 | 2 | 66.7 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.4 |

| 3/4 | 20 | 115 | 14.3 | 42.9 | 2 | 82.6 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 50.8 | 2 | 88.9 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 63.5 | 2 | 98.4 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 73 | 2 | 114.3 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 92.1 | 2 | 127 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 2 1/2 | 65 | 190 | 23.9 | 104.8 | 2 | 149.2 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 5.5 |

| 3 | 80 | 210 | 27 | 127 | 2 | 168.3 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 7.3 |

| 3 1/2 | 90 | 230 | 28.6 | 139.7 | 2 | 184.2 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 9.6 |

| 4 | 100 | 255 | 30.2 | 157.2 | 2 | 200 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 12.3 |

| 5 | 125 | 280 | 33.4 | 185.7 | 2 | 235 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 15.9 |

| 6 | 150 | 320 | 35 | 215.9 | 2 | 269.9 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 22.7 |

| 8 | 200 | 380 | 39.7 | 269.9 | 2 | 330.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 36 |

| 10 | 250 | 445 | 46.1 | 323.8 | 2 | 387.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 57 |

| 12 | 300 | 520 | 49.3 | 381 | 2 | 450.8 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 84 |

| 14 | 350 | 585 | 52.4 | 412.8 | 2 | 514.4 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 113 |

| 16 | 400 | 650 | 55.6 | 469.9 | 2 | 571.5 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 134 |

| 18 | 450 | 710 | 58.8 | 533.4 | 2 | 628.6 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 181 |

| 20 | 500 | 775 | 62 | 584.2 | 2 | 685.8 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 230 |

| 24 | 600 | 915 | 68.3 | 692.2 | 2 | 812.8 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 359 |