We received a new inquiry about ASTM A182 F12 socket weld fittings and flanges.The client is from Nigeria.

The socket weld fittings are our major products.Our prices are competitive although the alloy forged steel fittings are uncommon.

One month later, the client place the order. It is a good start for the first cooperation for both of us.

Purchase Order List

| NO | Description | Name | Size | Quantity (EA) |

| 1 | A182-F12 3000 SW | 90ELBOW | 1” | 188 |

| 2 | A182-F12 600 WN XS RF (SM) | FLANGE | 3/4” | 150 |

| 5 | A182-F12 FULL 3000 SW | COUPLING | 3/4” | 11 |

| 6 | A182-F12 3000 SW | TEE | 1” X 1” | 35 |

| 7 | A182-F12 3000 SW | TEE | 3/4” X 3/4” | 20 |

Socket Weld Fittings Specification and Types

Socket weld fittings are a type of pipe attachment ,commonly used on smaller diameter high-pressure pipelines. Socket weld fittings are attached by inserting the pipe into the socket end and applying fillet weld around the top. This produces a smooth bore and better fluid or gas flow within the pipe.

Socket weld fittings are using seal welding process as they are usually in small dimensions below 4 inch. Manufacturing standards complied to ASME B16.11/MSS SP-79/MSS SP-97/MSS SP-83. Material also in carbon, alloy and stainless steel.

Types of Socket Weld Fittings

Similar to butt weld fittings, socket weld fittings are available in various material types, including stainless steel, carbon steel, and alloy steel. These fittings are used in a wide range of applications and include socket weld elbows,tees,reducing tees, couplings, boss,caps,inserts,unions,outlets,etc.

| Size: | 1/4″ to 4″ ( DN6 to DN100) |

| Pressure Rating: | Class 3000, 6000, 9000 LBS |

| Standard: | ASME B16.11, BS3799, MSS SP-79 / 83 / 85 / 97 |

| Type: | socket weld elbow, tee, cross, cap, coupling, boss, lateral, reducer insert and union. |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L |

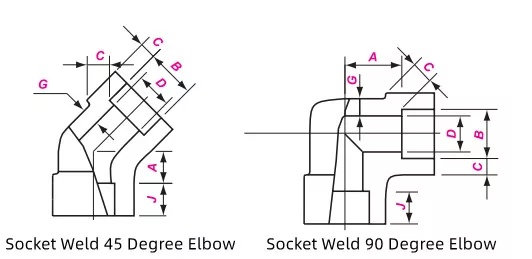

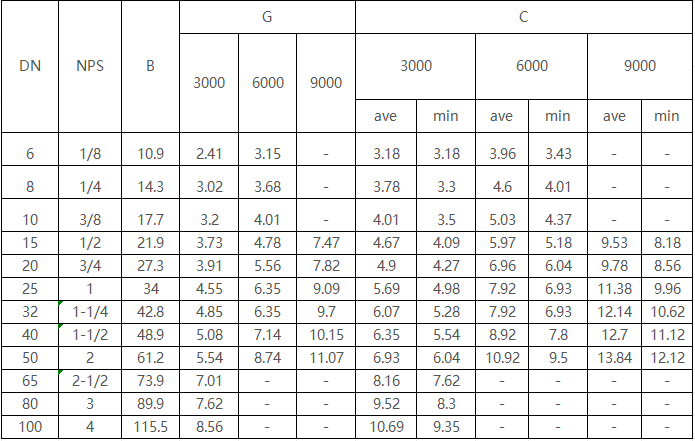

Dimension and Weight of Socket Weld 90 Degree Elbow

ASME B16.11 forged socket weld elbow is available in 90 degree and 45 degree that used to connect the ASME pipe to fittings or valves by fillet seal welding. The weight is light due to small size dimensions. And has varieties of features such as reliability, durability and dimensional precision. There are 3 pressure ratings that Class 3000, 6000 and 9000.

Class 3000 Elbow: for using with Sch 80 steel pipe.

Class 6000 Elbow: for matching with Sch 160 steel pipe.

Class 9000 Elbow: for connecting with Sch XXS steel pipe

ASME B16.11 Socket Weld Elbow Fittings Dimensions

1) The even thickness around the socket bore shall not be less than the average value, the thickness at partial areas can be the min. one.

2) Considering the tolerance of outside diameter of pipe, the diameters of some socket bore can be a little larger than the ones specified in B16.11.

3) When the sizes of the connecting pipes are not conformed to the ones specified in this catalog, the sizes of the connecting pipes shall be provided in the purchase specification.

4) When the fittings are reducing,the structure sizes shall be same as the ones of the straight fittings and B J D shall be machined per the according reducing ends.

5) Fitting can also be manufactured as the mixed connectings of SW and THRD.

Weight Chart in KG

| NOMINAL SIZE | SW 90 DEGREE ELBOW | SW 45 DEGREE ELBOW | |||||

| DN | NPS | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.09 | 0.15 | – | 0.08 | 0.16 | – |

| 8 | 1/4 | 0.09 | 0.15 | – | 0.08 | 0.16 | – |

| 10 | 3/8 | 0.12 | 0.32 | – | 0.12 | 0.28 | |

| 15 | 1/2 | 0.26 | 0.4 | 0.85 | 0.22 | 0.3 | 0.78 |

| 20 | 3/4 | 0.35 | 0.65 | 1.48 | 0.28 | 0.72 | 1.25 |

| 25 | 1 | 0.52 | 1.25 | 2.2 | 0.55 | 0.9 | 1.85 |

| 32 | 1-1/4 | 0.85 | 1.4 | 2.9 | 0.71 | 1.15 | 2.62 |

| 40 | 1-1/2 | 1.05 | 2.35 | 3.5 | 0.89 | 1.9 | 3.45 |

| 50 | 2 | 1.75 | 2.96 | 4.35 | 1.3 | 2.95 | 5.8 |

| 65 | 2-1/2 | 2.8 | – | – | 2.68 | – | – |

| 80 | 3 | 4.6 | – | – | 4.9 | – | – |

| 100 | 4 | 9.6 | – | – | 8.8 | – | – |

Package of Socket Weld Fittings

Pack all SW elbows in cartons.

Stick label on all cartons.

Put cartons into wooden box.

Make shipping mark on wooden box.