ASTM A312 is a standard developed by the American Society for Testing and Materials for austenitic seamless and welded steel pipes. Suitable for various types of pipelines, and regulations have been made for the manufacturing, performance, and temperature of materials.

This standard including austenitic stainless steel, duplex stainless steel, and martensitic stainless steel. These stainless steel materials have good corrosion resistance and strength.

Characteristics Of Stainless Steel Pipes

The characteristics of ASTM A312 stainless steel pipes are mainly reflected in chemical composition, mechanical properties, and manufacturing process.

The corrosion resistance of stainless steel pipes are mainly attributed to their alloy composition. For example, ASTM A312 TP304/316 contain alloying elements such as chromium and nickel, which can improve the corrosion resistance of steel pipes.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A312 TP304L | MIN | 8.00 | 18.00 | \ | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | \ | \ | |

| ASTM A312 TP316L | MIN | 10.00 | 16.00 | 2.00 | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | \ | |

| ASTM A312 TP317L | MIN | 11.00 | 18.00 | 3.00 | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 15.00 | 20.00 | 4.00 | \ | |

| ASTM A312 TP321 | MIN | 9.00 | 17.00 | \ | \ | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 | \ | 0.10 | |

| ASTM A312 TP347 | MIN | 9.00 | 17.00 | \ | \ | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 19.00 | \ | \ |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A312 TP304L | 485 min | 170 min | 35 min |

| ASTM A312 TP316L | 485 min | 170 min | 35 min |

| ASTM A312 TP317L | 515 min | 205 min | 35 min |

| ASTM A312 TP321 | 515 min | 205 min | 35 min |

| ASTM A312 TP347 | 515 min | 205 min | 35 min |

In manufacturing process, the standard specifies the manufacturing methods for seamless steel pipes and welded steel pipes. Seamless steel pipes are manufactured through cold or hot processing.Welded steel pipes are manufactured through methods such as automatic welding, manual welding, or combination welding.

In addition, there are various types and specifications of ASTM A312 stainless steel pipes.It can meet the needs of different industries.

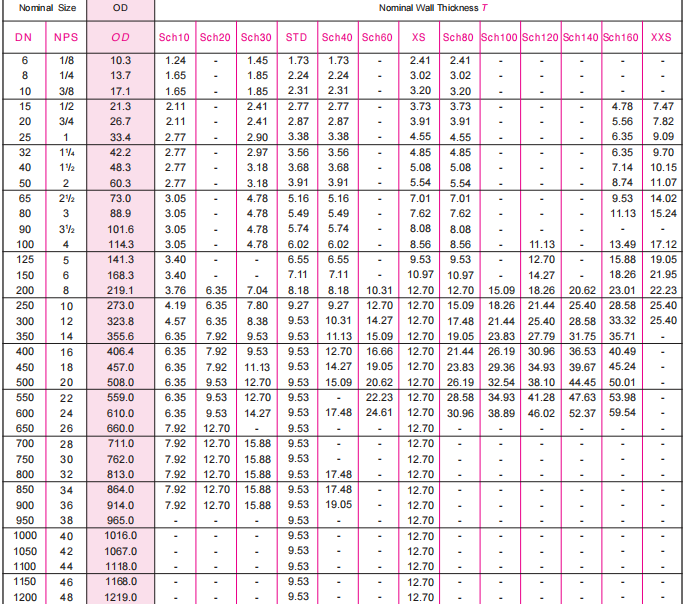

Dimension Of Stainless Steel Pipes

Stainless steel pipes commonly used outer diameter ranges from 1/8 inch to 48 inches.The wall thickness includes SCH10S, SCH40S, SCH80S, etc. The production standards for ASTM A312 stainless steel pipes are in accordance with American standards ASME B36.10M and ASME B36.19M.Its strict manufacturing process and quality control also ensure its stability and reliability during use.

ASTM A312 stainless steel pipes are widely used in the chemical industry, petroleum and natural gas industry, food and pharmaceutical industry, and other fields.