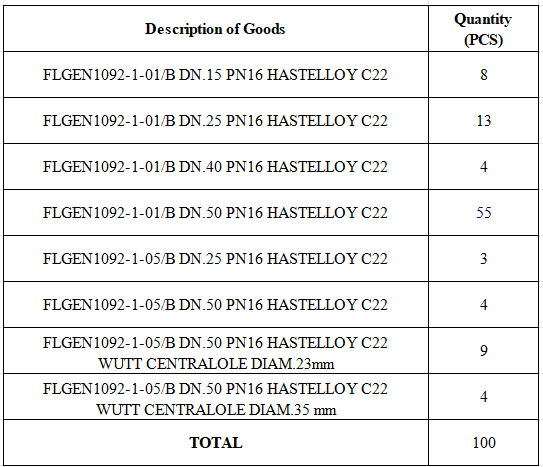

Last week, we just completed an order for Hastelloy C22(UNS N06022) alloy flange. This order come from regular customer from Italy,he has a pleasant cooperative with us. This customer trusts us very much,so we have successfully obtained this important order.We did not disappoint the customer’s trust and quickly completed the delivery of the order.

Purchase Order List

Hastelloy C22 Materials

Hastelloy C22 is a high-end nickel based alloy primarily based on nickel, chromium, and molybdenum, and contains tungsten and small amounts of iron. Its main chemical components include nickel (50% -60%), chromium (20.0% -22.5%), molybdenum (12.5% -14.5%), iron (2% -6%), and tungsten (2.5% -3.5%). This unique chemical ratio endows Hastelloy C22 with some special performance advantages, such as strong acid corrosion resistance, excellent resistance to wet chlorine and chlorine oxidation environments, as well as excellent stability in atmospheric and cold reduced desalination acids and acidified salts.

Chemical Composition

| Ni | Fe | Mn | C | Si | S | Cr | Mo | P | W | Co | V | |

| MIN | Balance | 2.00 | 20.00 | 12.50 | 2.50 | |||||||

| MAX | 6.00 | 0.50 | 0.02 | 0.08 | 0.02 | 22.50 | 14.50 | 0.02 | 3.50 | 2.50 | 0.35 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| Hastelloy C22 | 690 min | 310 min | 45 min |

Hastelloy C22 Flange

Hastelloy C22 corresponds to the American standard material grade ASTM B564 UNS N06022. As a high mechanical properties and highly corrosion-resistant material. It has excellent oxidation resistance, acid and alkali resistance, corrosion resistance, high temperature performance, and good mechanical properties. The flange is forged using Hastelloy C22 as the raw material, which has extremely strong corrosion resistance and can resist the erosion of various strong acidic solutions such as acid, hydrochloric acid, and hydrofluoric acid. It has extremely high corrosion resistance to various acidic environments. Hastelloy C22 flange has excellent heat resistance. Can be used for a long time in high-temperature environments, and has excellent mechanical properties, high hardness, high compressive strength, and wear resistance. Therefore, it is widely used in various fields such as petrochemicals, chemicals, and electricity.

| Material | Hastelloy C22 / ASTM B564 UNS N06022 |

| Technique Use In Forging | Forged, Heat treated,& machined |

| Flanges Types | Plate Flange&Blind Flange |

| Size | DN10-DN1200 |

| Pressure Ratings | PN6 PN10 PN16 PN25 PN40 PN60 PN100 PN160 PN250 |

| Standards | EN1092-1 |

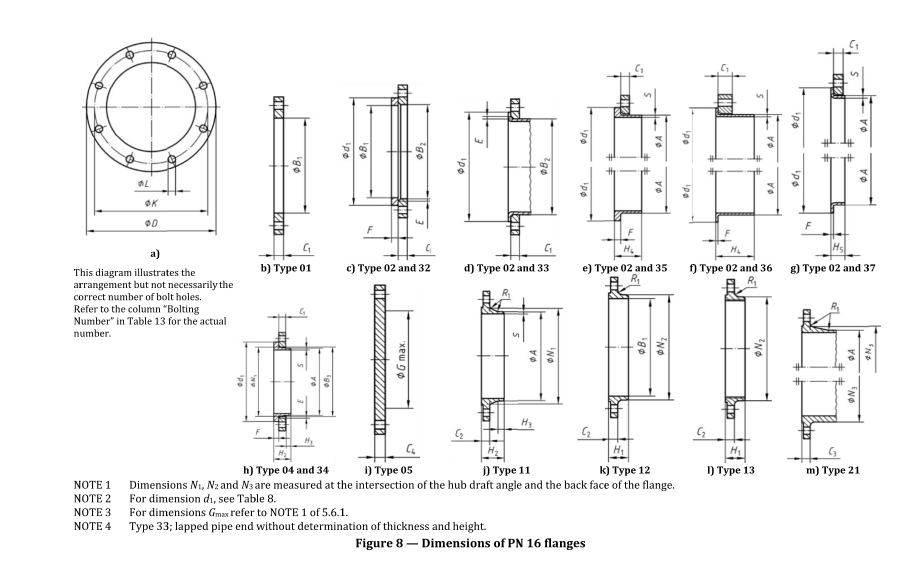

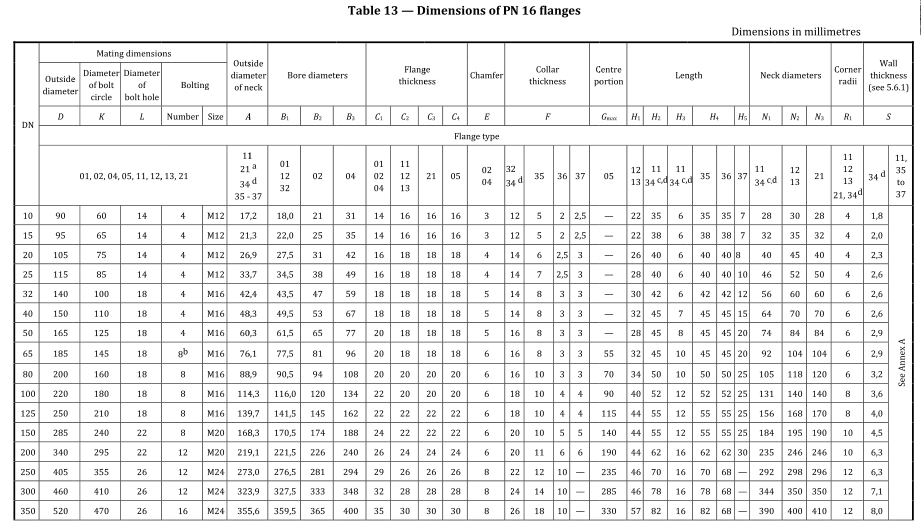

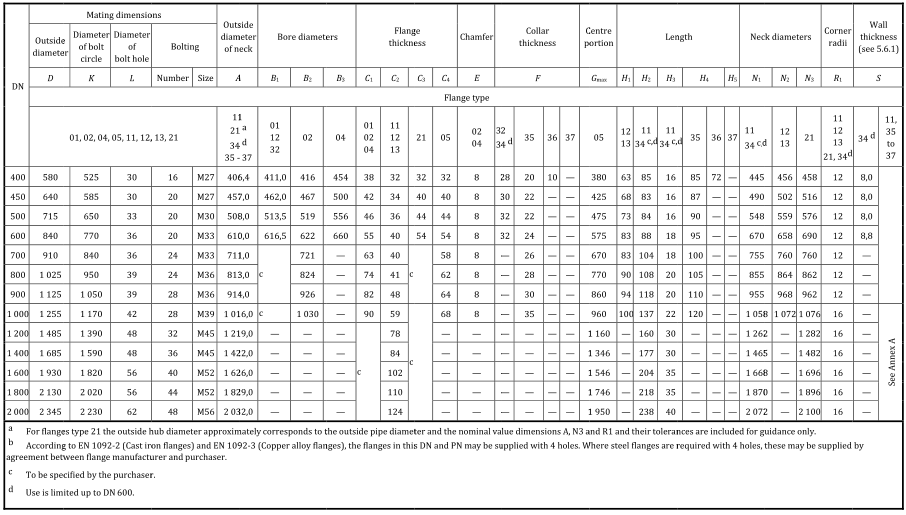

Dimension Of Hastelloy C22 Flange

This batch of Hastelloy C22 flange orders requires the customer to produce according to the production standard EN1092-1. EN1092-1 is a production standard for flanges, which defines the requirements for flange size, shape, surface treatment, pressure rating, and flange type, and specifies the structure, material, and static calculation method of flanges to meet the needs of different application scenarios.

After the order was completed, we conducted a factory inspection on this batch of flanges to ensure that the Hastelloy C22 flanges received by the customer meet the parameter requirements of EN1092-1 standard.

Dimension Of EN1029-1 PN16 Flange