Canada shipyard customer purchased Alu 6061 T6 Flange ,90 Degree Elbow, Equal Tee, Concentric Reducer Pipe Fittings from Zizi Engineering.Since we have cooperated on pipe, fittings & flanges in both stainless steel and carbon steel before, so this order is placed to us smoothly,

Purchase Order Details

| No | Description | Material |

| 1 | Tee 4 inch Sch 40 Butt Weld ASME 16.9 | ALUMINUM 6061-T6 |

| 2 | 4 inch Sch 40 90 Degree Elbow LR Butt Weld ASME 16.9 | ALUMINUM 6061-T6 |

| 3 | Concentric Reducer 3 inch to 2 inch Sch 40 ASME 16.9 | ALUMINUM 6061-T6 |

| 4 | 4” #150 Slip-on Flange ASME 16.5 | ALUMINUM 6061-T6 |

| 5 | 5” #150 Slip-on Flange ASME 16.5 | ALUMINUM 6061-T6 |

| 6 | 5” Sch 40 180 Degree Elbow LR Butt Weld ASME 16.9 | ALUMINUM 6061-T6 |

Standard Specification for Aluminum-Alloy 6061-T6

ASTM B308/B308M specification covers extruded 6061-T6 aluminum-alloy standard structural profiles that are limited to I-beams H-beams, channels, angles, tees and zees. They are sensitive to high temperatures, when reach about 200-250°C, they will lose some of their strength. However, their strength can be increased at subzero temperatures. They have good corrosion resistance feature as stainless steel.

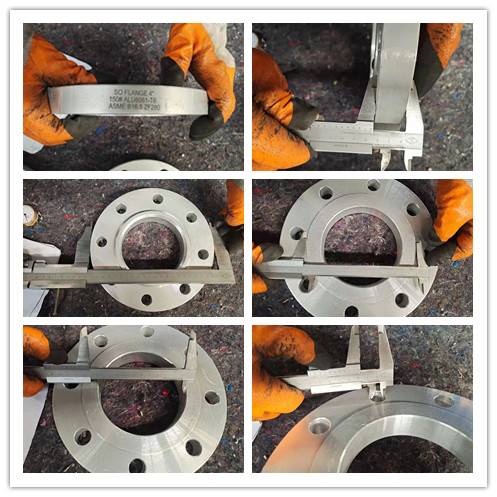

Inspection of Alu 6061 T6 Flanges and Fittings

For the Slip-on flanges. we inspected the outside diameter, iameter at bease of Hub, OD of raised face, bore and thickness and length thru hub.

For butt weld fittings, we measured the outside diameter and thickness, also the degree for elbows, height of tees and concentric reducers.

Chemical Composition Limits

| Alloy 6061 | Composition % |

| Silicon | 0.4 – 0.8 |

| Iron | 0.7 |

| Copper | 0.15 – 0.4 |

| Manganese | 0.15 |

| Magnesium | 0.8 – 1.2 |

| Chromium | 0.04 – 0.35 |

| Zinc | 0.25 |

| Titanium | 0.15 |

| Other elements each | 0.05 |

| Total E | 0.15 |

| Aluminum | Remainder |

Tensile Property Limits

| 6061 T6 | Data |

| Tensile Strength min ( MPa) | 260 |

| Yield Strength min ( MPa) | 240 |

| Elongation min % | 10 |