- Home

- Blog Custom Layout

- Forged Steel Flanges

- Weld Neck Flange

Weld Neck Flange

Weld neck flange provides a long tapered hub for welding to pipes , it is used in high pressure systems and suitable for both cold and hot temperatures. Generally machined by forging method, these flanges are typically butt welded to the pipe,when you are going to buy weld neck flange, it is important to specify the pipe thickness schedule. Because the flange inside diameter will match the inside diameter of pipe. The rim has a series of drilled holes that permit the flange to be affixed to another flange with bolts.

Forged Steel Flange Standard

- ASME B16.5

- ASME B16.47A

- ASME B16.47B

- JIS B2220

- KS B1503

- DIN 2573

- DIN 2527

- DIN 2631

- BS 4504

- API 6A

Pressure Rating for Weld Neck Flange

ANSI FLANGES

Class 150, 300, 600, 900, 1500, 2500

JIS FLANGES

5K, 10K, 16K, 20K, 30K

DIN FLANGES

PN6, PN10, PN16, PN25, PN40, PN64, PN100

API FLANGES

2000PSI, 3000PSI, 5000PSI, 10000PSI, 15000PSI, 20000PSI

Material for Steel Pipe Flange

Stainless Steel Flange

ASTM/ASME A/SA182 F304, F304L, F316, F316L, F321, F904L, F310S,DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409

Carbon Steel Flange

ASTM/ASME A/SA105 A/SA105N, DIN 1.0402, DIN 1.0460, DIN 1.0619,ASTM A350 LF2 / LF3, ASTM A694 / A694 F52 / F56 / F60 / F65 / F70 / F80

Alloy Steel Flange

ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91

Nickel Weld Neck Flange

ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205

Hastelloy Flange

ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3

Duplex Steel Flange

S31803 / S32205 / S32750 / S32760 ASTM A182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61

Aluminium Flange

5052 /6061/ 6063 / 2017 / 7075

Weld Neck Flange Advantages

- Durable connection.

- Leakage prevention.

- Ease of installation.

- Testing of the pipe and joints are easier.

- The flange face is kept away from heat affected area.

- Suitable for high pressure and high heat applications.

- Facilitates easy access for radiography testing to check the integrity of welding.

- The weld connection does not interfere with flow of the fluid and reduces turbulence.

ASME B16.5 Weld Neck Flanges Dimensions

ASME B16.5 standard weld neck flanges are availbale in 1/2 ” to 24” nominal sizes and in pressure of Class 150#, 300#, 600#, 900#, 1500#, and 2500# . There are many seal facing as Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) , Tongue-and-Groove (T&G) and Male-and-Female (M&F).

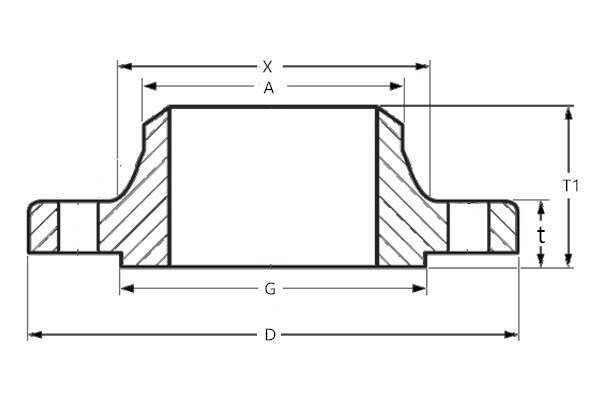

ASME B16.5 Weld Neck Flange Drawing

| Weld Neck Flanges Class 150 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 89 | 15.7 | 4 | 11.2 | 47.8 | 30.2 | 21.3 | 35.1 | 0.5 |

| 3/4″ | 99 | 20.8 | 4 | 12.7 | 52.3 | 38.1 | 26.7 | 42.9 | 0.9 |

| 1″ | 108 | 26.7 | 4 | 14.2 | 55.6 | 49.3 | 33.5 | 50.8 | 1.1 |

| 1-1/4″ | 117 | 35.1 | 4 | 15.7 | 57.2 | 58.7 | 42.2 | 63.5 | 1.4 |

| 1-1/2″ | 127 | 40.9 | 4 | 17.5 | 62 | 65 | 48.3 | 73.2 | 1.8 |

| 2″ | 152 | 52.6 | 4 | 19.1 | 63.5 | 77.7 | 60.5 | 91.9 | 2.8 |

| 2-1/2″ | 178 | 62.7 | 4 | 22.4 | 69.9 | 90.4 | 73.2 | 104.6 | 4.3 |

| 3″ | 191 | 78 | 4 | 23.9 | 69.9 | 108 | 88.9 | 127 | 5.2 |

| 3-1/2″ | 216 | 90.2 | 8 | 23.9 | 71.4 | 122.2 | 101.6 | 139.7 | 5.5 |

| 4″ | 229 | 102.4 | 8 | 23.9 | 76.2 | 134.9 | 114.3 | 157.2 | 7.3 |

| 5″ | 254 | 128.3 | 8 | 23.9 | 88.9 | 163.6 | 141.2 | 185.7 | 8.9 |

| 6″ | 279 | 154.2 | 8 | 25.4 | 88.9 | 192 | 168.4 | 215.9 | 11.3 |

| 8″ | 343 | 202.7 | 8 | 28.4 | 101.6 | 246.1 | 219.2 | 269.7 | 18.1 |

| 10″ | 406 | 254.5 | 12 | 30.2 | 101.6 | 304.8 | 273.1 | 323.9 | 25.0 |

| 12?” | 483 | 304.8 | 12 | 31.8 | 114.3 | 365.3 | 323.9 | 381 | 39.0 |

| 14″ | 533 | 336.6 | 12 | 35.1 | 127 | 400.1 | 355.6 | 412.8 | 51.7 |

| 16″ | 597 | 387.4 | 16 | 36.6 | 127 | 457.2 | 406.4 | 469.9 | 64.5 |

| 18″ | 635 | 438.2 | 16 | 39.6 | 139.7 | 505 | 457.2 | 533.4 | 75.0 |

| 20″ | 699 | 489.0 | 20 | 42.9 | 144.5 | 558.8 | 508 | 584.2 | 89.5 |

| 24″ | 813 | 590.6 | 20 | 47.8 | 152.4 | 663.4 | 609.6 | 692.2 | 120 |

| Weld Neck Flanges Class 300 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 95 | 15.7 | 4 | 14.2 | 52.3 | 38.1 | 21.3 | 35.1 | 0.8 |

| 3/4″ | 117 | 20.8 | 4 | 15.7 | 57.2 | 47.8 | 26.7 | 42.9 | 1.4 |

| 1″ | 124 | 26.7 | 4 | 17.5 | 62 | 53.8 | 33.5 | 50.8 | 1.6 |

| 1-1/4″ | 133 | 35.1 | 4 | 19.1 | 65 | 63.5 | 42.2 | 63.5 | 2.1 |

| 1-1/2″ | 155 | 40.9 | 4 | 20.6 | 68.3 | 69.9 | 48.3 | 73.2 | 3.1 |

| 2″ | 165 | 52.6 | 8 | 22.1 | 69.9 | 84.1 | 60.5 | 91.9 | 3.5 |

| 2-1/2″ | 191 | 62.7 | 8 | 25.4 | 76.2 | 100.1 | 73.2 | 104.6 | 5.3 |

| 3″ | 210 | 78 | 8 | 28.4 | 79.2 | 117.3 | 88.9 | 127 | 7.3 |

| 3-1/2″ | 229 | 90.2 | 8 | 30.2 | 81 | 133.4 | 101.6 | 139.7 | 8.2 |

| 4″ | 254 | 102.4 | 8 | 31.8 | 85.9 | 146.1 | 114.3 | 157.2 | 11.3 |

| 5″ | 279 | 128.3 | 8 | 35.1 | 98.6 | 177.8 | 141.2 | 185.7 | 15.1 |

| 6″ | 318 | 154.2 | 12 | 36.6 | 98.6 | 206.2 | 168.4 | 215.9 | 20.0 |

| 8″ | 381 | 202.7 | 12 | 41.1 | 1 | 260.4 | 219.2 | 269.7 | 30.5 |

| 11.3 | |||||||||

| 10″ | 445 | 254.5 | 16 | 47.8 | 117.3 | 320.5 | 273.1 | 323.9 | 4.8 |

| 12″ | 521 | 303.2 | 16 | 50.8 | 130 | 374.7 | 323.9 | 381 | 64.5 |

| 14″ | 584 | 333.3 | 20 | 53.8 | 142.7 | 425.5 | 355.6 | 412.8 | 88.3 |

| 16″ | 648 | 381 | 20 | 57.2 | 146.1 | 482.6 | 406.4 | 469.9 | 115.0 |

| 18″ | 711 | 428.7 | 24 | 60.5 | 158.8 | 533.4 | 457.2 | 533.4 | 143.0 |

| 20″ | 775 | 477.8 | 24 | 63.5 | 162.1 | 587.2 | 508 | 584.2 | 175.0 |

| 24″ | 914 | 575 | 24 | 69.9 | 168.1 | 701.5 | 609.6 | 692.2 | 260.0 |

| Weld Neck Flanges Class 600 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 95 | 15.7 | 4 | 14.2 | 52.3 | 38.1 | 21.3 | 35.1 | 1.0 |

| 3/4″ | 117 | 20.8 | 4 | 15.7 | 57.2 | 47.8 | 26.7 | 42.9 | 1.6 |

| 1″ | 124 | 26.7 | 4 | 17.5 | 62 | 53.8 | 33.5 | 50.8 | 2.2 |

| 1-1/4″ | 133 | 35.1 | 4 | 20.6 | 66.5 | 63.5 | 42.2 | 63.5 | 2.8 |

| 1-1/2″ | 155 | 40.9 | 4 | 22.4 | 69.9 | 69.9 | 48.3 | 73.2 | 3.8 |

| 2″ | 165 | 52.6 | 8 | 25.4 | 73.2 | 84.1 | 60.5 | 91.9 | 4.5 |

| 2-1/2″ | 191 | 62.7 | 8 | 28.4 | 79.2 | 100.1 | 73.2 | 104.6 | 8.2 |

| 3″ | 210 | 78 | 8 | 31.8 | 82.6 | 117.3 | 88.9 | 127 | 8.8 |

| 3-1/2″ | 229 | 90.2 | 8 | 35.1 | 85.9 | 133.4 | 101.6 | 139.7 | 12.0 |

| 4″ | 273 | 102.4 | 8 | 38.1 | 101.6 | 152.4 | 114.3 | 157.2 | 17.0 |

| 5″ | 330 | 128.3 | 8 | 44.5 | 114.3 | 189 | 141.2 | 185.7 | 31.0 |

| 6″ | 356 | 154.2 | 12 | 47.8 | 117.3 | 222.3 | 168.4 | 215.9 | 37.0 |

| 8″ | 419 | 202.7 | 12 | 55.6 | 133.4 | 273.1 | 219.2 | 269.7 | 55.0 |

| 10″ | 508 | 254.5 | 16 | 63.5 | 152.4 | 342.9 | 273.1 | 323.9 | 90.0 |

| 12″ | 559 | 303.2 | 20 | 66.5 | 155.4 | 400.1 | 323.9 | 381 | 110.0 |

| 14″ | 603 | 333.3 | 20 | 69.9 | 165.1 | 431.8 | 355.6 | 412.8 | 127.0 |

| 16″ | 686 | 381 | 20 | 76.2 | 177.8 | 495.3 | 406.4 | 469.9 | 177.1 |

| 18″ | 743 | 428.4 | 20 | 82.6 | 184.2 | 546.1 | 457.2 | 533.4 | 215.65 |

| 20″ | 813 | 477.8 | 24 | 88.9 | 190.5 | 609.6 | 508 | 584.2 | 267.9 |

| 24″ | 940 | 575 | 24 | 101.6 | 203.2 | 717.6 | 609.6 | 692.2 | 372.0 |

| Weld Neck Flanges Class 900 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 121 | 15.7 | 4 | 22.4 | 60.5 | 38.1 | 21.3 | 34.9 | 1.9 |

| 3/4″ | 130 | 20.8 | 4 | 25.4 | 69.9 | 44.5 | 26.7 | 42.9 | 2.6 |

| 1″ | 149 | 26.7 | 4 | 28.4 | 73.2 | 52.3 | 33.5 | 50.8 | 3.8 |

| 1-1/4″ | 159 | 35.1 | 4 | 28.4 | 73.2 | 63.5 | 42.2 | 63.5 | 4.3 |

| 1-1/2″ | 178 | 40.9 | 4 | 31.8 | 82.6 | 69.9 | 48.3 | 73 | 6.0 |

| 2″ | 216 | 52.6 | 8 | 38.1 | 101.6 | 104.6 | 60.5 | 92.1 | 10.8 |

| 2-1/2″ | 244 | 62.7 | 8 | 41.1 | 104.6 | 124 | 73.2 | 104.8 | 15.0 |

| 3″ | 241 | 78 | 8 | 38.1 | 101.6 | 127 | 88.9 | 127 | 13.7 |

| 4″ | 292 | 102.4 | 8 | 44.5 | 114.3 | 158.8 | 114.3 | 157.2 | 22.5 |

| 5″ | 349 | 128.3 | 8 | 50.8 | 127 | 190.5 | 141.2 | 185.7 | 37.4 |

| 6″ | 381 | 154.2 | 12 | 55.6 | 139.7 | 235 | 168.4 | 215.9 | 47.7 |

| 8″ | 470 | 202.7 | 12 | 63.5 | 162.1 | 298.5 | 219.2 | 269.9 | 81.3 |

| 10″ | 546 | 254.5 | 16 | 69.9 | 184.2 | 368.3 | 273.1 | 323.8 | 119.0 |

| 12″ | 610 | 304.8 | 20 | 79.2 | 200.2 | 419.1 | 323.9 | 381 | 157.0 |

| 14″ | 641 | 336.6 | 20 | 85.9 | 212.9 | 450.9 | 355.6 | 412.8 | 180.0 |

| 16″ | 705 | 387.1 | 20 | 88.9 | 215.9 | 508 | 406.4 | 469.9 | 217.0 |

| 18″ | 787 | 438.2 | 20 | 101.6 | 228.6 | 565.2 | 457.2 | 533.4 | 292.0 |

| 20″ | 857 | 489 | 20 | 108 | 247.7 | 622.3 | 508 | 584.2 | 362.0 |

| 24″ | 1041 | 590.6 | 20 | 139.7 | 292.1 | 749.3 | 609.6 | 692.2 | 665.0 |

| Weld Neck Flanges Class 1500 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 121 | 15.7 | 4 | 22.4 | 60.5 | 38.1 | 21.3 | 34.9 | 1.9 |

| 3/4″ | 130 | 20.8 | 4 | 25.4 | 69.9 | 44.5 | 26.7 | 42.9 | 2.6 |

| 1″ | 149 | 26.7 | 4 | 28.4 | 73.2 | 52.3 | 33.5 | 50.8 | 3.8 |

| 1-1/4″ | 159 | 35.1 | 4 | 28.4 | 73.2 | 63.5 | 42.2 | 63.5 | 4.3 |

| 1-1/2″ | 178 | 40.9 | 4 | 31.3 | 82.6 | 69.9 | 48.3 | 73 | 6.0 |

| 2″ | 216 | 52.6 | 8 | 38.1 | 101.6 | 104.6 | 60.5 | 92.1 | 10.8 |

| 2-1/2″ | 244 | 62.7 | 8 | 41.1 | 104.6 | 124 | 73.2 | 104.3 | 150.0 |

| 3″ | 267 | 78 | 8 | 47.3 | 117.3 | 133.4 | 88.9 | 127 | 20.0 |

| 4″ | 311 | 102.4 | 8 | 53.8 | 124 | 162.1 | 114.3 | 157.2 | 30.0 |

| 5″ | 375 | 128.3 | 8 | 73.2 | 155.4 | 196.9 | 141.2 | 185.7 | 55.5 |

| 6″ | 394 | 154.2 | 12 | 82.6 | 171.5 | 228.6 | 168.4 | 215.9 | 68.5 |

| 8″ | 483 | 202.7 | 12 | 91.9 | 212.9 | 292.1 | 219.2 | 269.9 | 117.0 |

| 10″ | 584 | 254.5 | 12 | 108 | 254 | 368.3 | 273.1 | 323.8 | 194.0 |

| 12″ | 673 | 304.8 | 16 | 124 | 282.4 | 450.9 | 323.9 | 381 | 288.0 |

| 14″ | 749 | 336.6 | 16 | 133.4 | 298.5 | 495.3 | 355.6 | 412.8 | 380.0 |

| 16″ | 826 | 387.1 | 16 | 146.1 | 311.2 | 552.5 | 406.4 | 469.9 | 485.0 |

| 18″ | 914 | 438.2 | 16 | 162.1 | 327.2 | 596.9 | 457.2 | 533.4 | 644.0 |

| 20″ | 984 | 489 | 16 | 177.8 | 355.6 | 641.4 | 508 | 584.2 | 775.0 |

| 24″ | 1168 | 590.6 | 16 | 203.2 | 406.4 | 762 | 609.6 | 692.2 | 1232.0 |

| Weld Neck Flanges Class 2500 LBS Dimensions | |||||||||

| NPS | A | B1 | Holes | T1 | D | X | A | G | Weight |

| 1/2″ | 121 | 15.7 | 4 | 22.4 | 60.5 | 38.1 | 21.3 | 34.9 | 3.1 |

| 3/4″ | 130 | 20.8 | 4 | 25.4 | 69.9 | 44.5 | 26.7 | 42.9 | 3.7 |

| 1″ | 149 | 26.7 | 4 | 28.4 | 73.2 | 52.3 | 33.5 | 50.8 | 5.3 |

| 1-1/4″ | 159 | 35.1 | 4 | 28.4 | 73.2 | 63.5 | 42.2 | 63.5 | 7.8 |

| 1-1/2″ | 178 | 40.9 | 4 | 31.3 | 82.6 | 69.9 | 48.3 | 73 | 10.9 |

| 2″ | 216 | 52.6 | 8 | 38.1 | 101.6 | 104.6 | 60.5 | 92.1 | 16.2 |

| 2-1/2″ | 244 | 62.7 | 8 | 41.1 | 104.6 | 124 | 73.2 | 104.3 | 23.7 |

| 3″ | 267 | 78 | 8 | 47.3 | 117.3 | 133.4 | 88.9 | 127 | 36.2 |

| 4″ | 311 | 102.4 | 8 | 53.8 | 124 | 162.1 | 114.3 | 157.2 | 55.3 |

| 5″ | 375 | 128.3 | 8 | 73.2 | 155.4 | 196.9 | 141.2 | 185.7 | 92.5 |

| 6″ | 394 | 154.2 | 12 | 82.6 | 171.5 | 228.6 | 168.4 | 215.9 | 143.0 |

| 8″ | 483 | 202.7 | 12 | 91.9 | 212.9 | 292.1 | 219.2 | 269.9 | 215.0 |

| 10″ | 584 | 254.5 | 12 | 108 | 254 | 368.3 | 273.1 | 323.8 | 406.0 |

| 12″ | 673 | 304.8 | 16 | 124 | 282.4 | 450.9 | 323.9 | 381 | 572.0 |