- Home

- Blog Custom Layout

- Stainless Steel Pipe Fittings

- Stainless Steel BSP Fittings

Stainless Steel BSP Fittings

USD52 USD50

316 and 304 Stainless Steel BSP Threaded Fittings Class 3000 & 6000

- General Details

- Chemical Properties

- Dimension Tolerance

- Related Products

5 Characteristics for Stainless Steel BSP Fittings

Corrosion Resistance

The most well-known advantage of stainless pipes fittings & flanges is their ability to hold up against corrosion, endure extreme temperatures. It is best choices to use them in corrosive environments.

Appearance

Exposed stainless steel threaded fittings are an excellent choice for commercial establishments as the material has a naturally shiny and elegant look.

Easy Installation

No need to do beveling preparation. Just screw the pipes into fittings sine they are light. But make sure the threads are same, otherwise, that may leak up the gas.

Low Cost

When you use stainless steel pipe fittings, it will last your business for many years. It is cheap because the size is small which below 4 inch. And low-maintenance due to its corrosion-resistant properties. You may no need to replace them for decades.

High Strength

Compared with mild steel, stainless steel have higher tensile strength. The duplex stainless steel have higher tensile strength than austenitic steel.

There are some many benefits for stainless steel BSP fittings, so please come to buy from us!

BSP Threaded Fittings Types

45 Degree Elbow

BSPP Threaded Cap

BSPP vs BSPT

BSPP thread is also British standard. It is a parallel thread fitting that uses a bonded seal ring to do the sealing. For historical reasons, BSPP has other different names at the same time. Such as BSPF ( British standard pipe fitting), BSPM(British Standard Pipe Mechanical) and PS (British Standard Pipe Straight) and so on.

BSPT thread is similar to NPT except for one important difference. The angle across the flanks of threads is 55 degrees instead of 60 degree as it is for NPT thread. Thus an NPT male thread could fit into BSPT female thread, but couldn’t sealing. That may make it dangerous while using.

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| ASTM A182 F304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 8.0-11.0 | 18.0-20.0 | |

| ASTM A182 F304H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 8.0-11.0 | 18.0-20.0 | |

| ASTM A182 F304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 8.0-13.0 | 18.0-20.0 | |

| ASTM A182 F309H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 12.0-15.0 | 22.0-24.0 | |

| ASTM A182 F310 | 0.25 | 2 | 0.045 | 0.03 | 1 | 19.0-22.0 | 24.0-26.0 | |

| ASTM A182 F310H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 19.0-22.0 | 24.0-26.0 | |

| ASTM A182 F316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F316H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F317 | 0.08 | 2 | 0.045 | 0.03 | 1 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 |

| ASTM A182 F317L | 0.03 | 2 | 0.045 | 0.03 | 1 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 |

| ASTM A182 F321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-12.0 | 17.0-19.0 | |

| ASTM A182 F321H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-12.0 | 17.0-19.0 | |

| ASTM A182 F347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F347H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F348 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F348H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 |

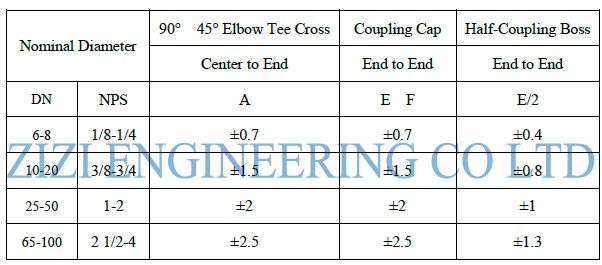

Dimension Tolerance for Threaded Pipe Fittings

Class 3000 Socket Weld Fittings

Socket Weld Fittings 1" Class 3000 Elbow ASTM A182 F316 ASME B16.11

USD16 USD15

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7