- Home

- Blog Custom Layout

- Steel Pipe Tees

- Stainless Steel Tee

Stainless Steel Tee

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Stainless steel tee is widely used in the piping system as well as steel pipe elbow, both of them can change the fluid direction of the pipeline.

We manufacture stainless steel pipe fittings in the common grade of SUS304 and SS316. And offer the best prices for the customer. Our pipe tees are available in a variety of connection types, sizes and package quantities.

Stainless Steel Tee Fitting Type

Shape Type:

Shape Types

Stainless Steel Equal Tee which means three branches have same diameters.

Stainless Steel Reducing Tee that means branch diameter is smaller than run pipe diameter.

Connection Type:

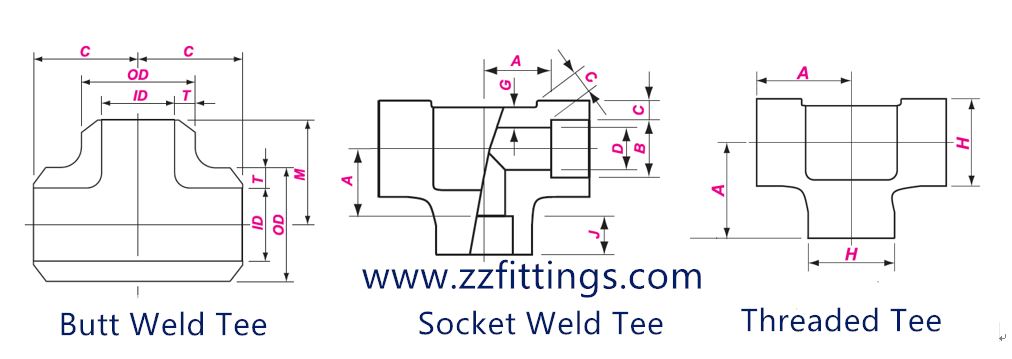

Butt Weld VS Socket Weld VS Threaded Tee

Socket Weld Tee is same as other socket weld fittings that the pipe is inserted and weld. Generally used in small diameter systems.

Threaded Pipe Tee is almost same as socket weld tee, but connecting with the pipe by screw.

Butt Weld Tee has plain or bevel end which used for easy weld on the pipe or other fittings.

ASME B16.9 & B16.11 Equal Tee Weight

The following weight chart are covering three types of equal tee, such as socket weld, butt weld and threaded.

| Nominal Size | Socket Weld Equal Tee | Threaded Equal Tee | Butt Weld Equal Tee | |||||||

| DN | NPS | 3000 LB | 6000 LB | 9000 LB | 2000 LB | 3000 LB | 6000 LB | SCH40S | SCH80S | SCH160 |

| 6 | 1/8 | 0.13 | 0.22 | 0.13 | 0.22 | 0.35 | ||||

| 8 | 1/4 | 0.13 | 0.22 | 0.13 | 0.22 | 0.57 | ||||

| 10 | 3/8 | 0.16 | 0.45 | 0.16 | 0.4 | 0.66 | ||||

| 15 | 1/2 | 0.35 | 0.55 | 1.15 | 0.35 | 0.58 | 1.15 | 0.2 | 0.2 | |

| 20 | 3/4 | 0.4 | 0.9 | 1.8 | 0.45 | 0.9 | 1.8 | 0.2 | 0.3 | |

| 25 | 1 | 0.66 | 1.46 | 2.25 | 0.66 | 1.46 | 2.25 | 0.3 | 0.5 | |

| 32 | 1 1/4 | 1 | 1.9 | 3.95 | 1 | 1.9 | 3.95 | 0.6 | 0.7 | |

| 40 | 1 1/2 | 1.4 | 3.4 | 4.87 | 1.4 | 3.4 | 4.87 | 0.9 | 1.3 | 1.5 |

| 50 | 2 | 2.2 | 3.7 | 8.89 | 2.2 | 3.8 | 8.89 | 1.5 | 2.2 | 2.7 |

| 65 | 2 1/2 | 4 | 7.2 | 4.2 | 7.2 | 12.8 | 2.7 | 3 | 3.1 | |

| 80 | 3 | 6.15 | 10.7 | 6.15 | 10.7 | 21.8 | 3.8 | 4.3 | 5.5 | |

| 100 | 4 | 14.3 | 14.7 | 17.9 | 29.5 | 4.6 | 6 | |||

Material & Grades for Stainless Steel Pipe Tee

ASTM A403 WP304/304L/304H, WP316/316L, WP310, WP317, WP321, WP309, WP347

ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321, F309, F347

Supply Range of Stainless Steel Pipe Fittings

Stainless Steel Butt Weld Fittings

| Standard | ASME B16.9 & B36.19 |

| Size Range | 1/2″, 1″, 2″, 3″, 4″, 6″, 8″, 10″, 12″, 16″, 20″, 24″ to 48″. |

| Thickness | SCH 10, SCH 40S, SCH 80S, SCH 160, XXS |

| Surface Coatings | Epoxy Coated, PE Coated |

| Product | 90 Degree Elbow, 45 Degree Elbow, Equal and Reducing Tee, Concentric & Eccentric Reducer, Pipe Cap and Stub End. |

Stainless Steel Forged Fittings

| Standard | ASME B16.11 & BS3799 |

| Size Range | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/2″, 2″, 2 1/2″, 3″, 4″. |

| Thickness | 2000LB, 3000LB, 6000LB, 9000LB |

| Surface Coatings | Anti-rust Oil. |

| Product | Stainless Steel Tee, Elbow, Cap, Coupling, Bushing, Nipple and Plug. |

316 Stainless Steel Properties

Chemical Composition

| GRADE | C | MN | SI | P | S | CR | MO | NI | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | – | – | – | 0 | – | 16 | 2 | 10 | – |

| Max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316L | Min | – | – | – | – | – | 16 | 2 | 10 | – |

| Max | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16 | 2 | 10 | – |

| max | 0.1 | 0.1 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | – |

Mechanical Properties

| GRADE | TENSILE STRENGTH | YIELD STRENGTH | ELONGATION | HARDNESS | |

|---|---|---|---|---|---|

| (MPA) MIN | (MPA) MIN | (% IN 50MM) MIN | (HR B) MAX | (HB) MAX | |

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

Stainless Steel Pipe Tee Drawing

Stainless Steel Pipe Tee Drawing

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

|---|---|---|---|---|

| DN | NPS | OD | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 48 | 48 |

| 40 | 1 1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2 1/2 | 73 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457 | 343 | 343 |

| 500 | 20 | 508 | 381 | 381 |

| 550 | 22 | 559 | 419 | 419 |

| 600 | 24 | 610 | 432 | 432 |

| 650 | 26 | 660 | 495 | 495 |

| 700 | 28 | 711 | 521 | 521 |

| 750 | 30 | 762 | 559 | 559 |

| 800 | 32 | 813 | 597 | 597 |

| 850 | 34 | 864 | 635 | 635 |

| 900 | 36 | 914 | 673 | 673 |

| 950 | 38 | 965 | 711 | 711 |

| 1000 | 40 | 1016 | 749 | 749 |

| 1050 | 42 | 1067 | 762 | 711 |

| 1100 | 44 | 1118 | 813 | 762 |

| 1150 | 46 | 1168 | 851 | 800 |

| 1200 | 48 | 1219 | 889 | 838 |

| 1300 | 52 | 1321 | 965 | 914 |

| 1400 | 56 | 1422 | 1041 | 965 |

| 1500 | 60 | 1524 | 1118 | 1016 |

| 1600 | 64 | 1626 | 1194 | 1092 |

| 1700 | 68 | 1727 | 1270 | 1168 |

| 1800 | 72 | 1829 | 1320 | 1245 |

| 1900 | 76 | 1930 | 1422 | 1320 |

| 2000 | 80 | 2032 | 1499 | 1397 |

Carbon Steel Eccentric Reducer

8” x 6” Sch 80 Eccentric Reducer BW ASTM A860 WPHY60 ASME B16.9

USD39 USD37

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55