- Home

- Blog Custom Layout

- Stub Ends

- Short Pattern Stub End

Short Pattern Stub End

USD7 USD6

Stub End Short Pattern 6“ Sch 40 ASTM A234 WPB BW MSS SP-43

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Stub end are available in long and short pattern with standard of MSS SP-43, the normal size is 4″, 6″ and 8″ Sch 40 which are butt weld connection type.

It is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same size, material and wall thickness. Stub end is one of buttweld fittings, the others are 45 degree elbow, 90 degree elbow, 180 degree elbow, straight and reducing tee, concentric and eccentric reducer, pipe caps.

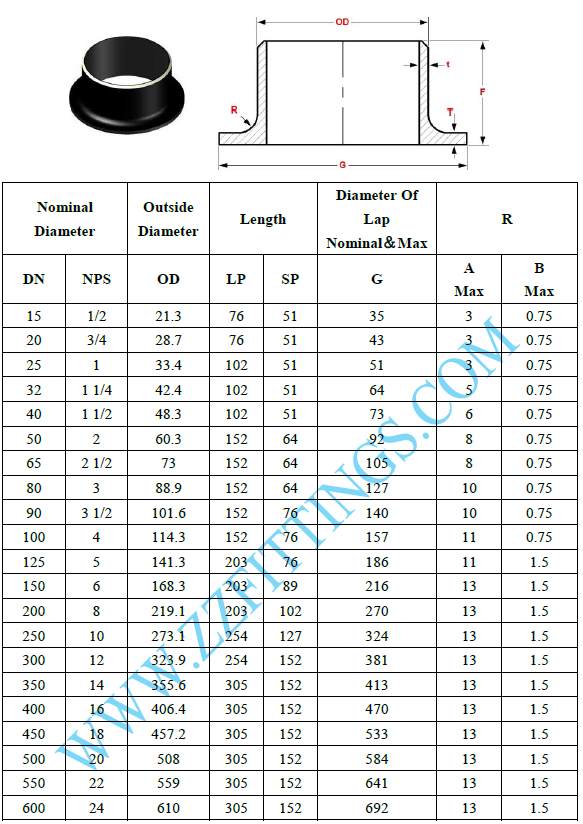

Short Pattern Stub End Dimensions

Standard: MSS SP-43, ASME B16.9

Size: NPS 1/2 to 24 / DN 15 to 600

Thickness: Sch 10S, 20, STD, 40, XS, 80, 100, 160, XXS

Short Pattern Stub End Dimensions

Material & Grades for Lap Joint Stub End

Stainless Steel Lap Joint Stub End

ASTM A403 WP304/304L/304H, WP316/316L, WP 309, WP310, WP317, WP321, WP347

Carbon Steel Stub End

ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, A420 WPL 3 / 6 / 9.

Alloy Steel Stub End Type A

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex Stainless Steel Short Stub End

ASTM A815 UNS S 31803, 32205, 32550, 32750, 32760

Package of Carbon Steel Buttweld Fittings

- Blasting and Painting.

- Wrapping plastic foam.

- Packing pipe fittings into wooden cases.

- Stick shipping mark on the package.

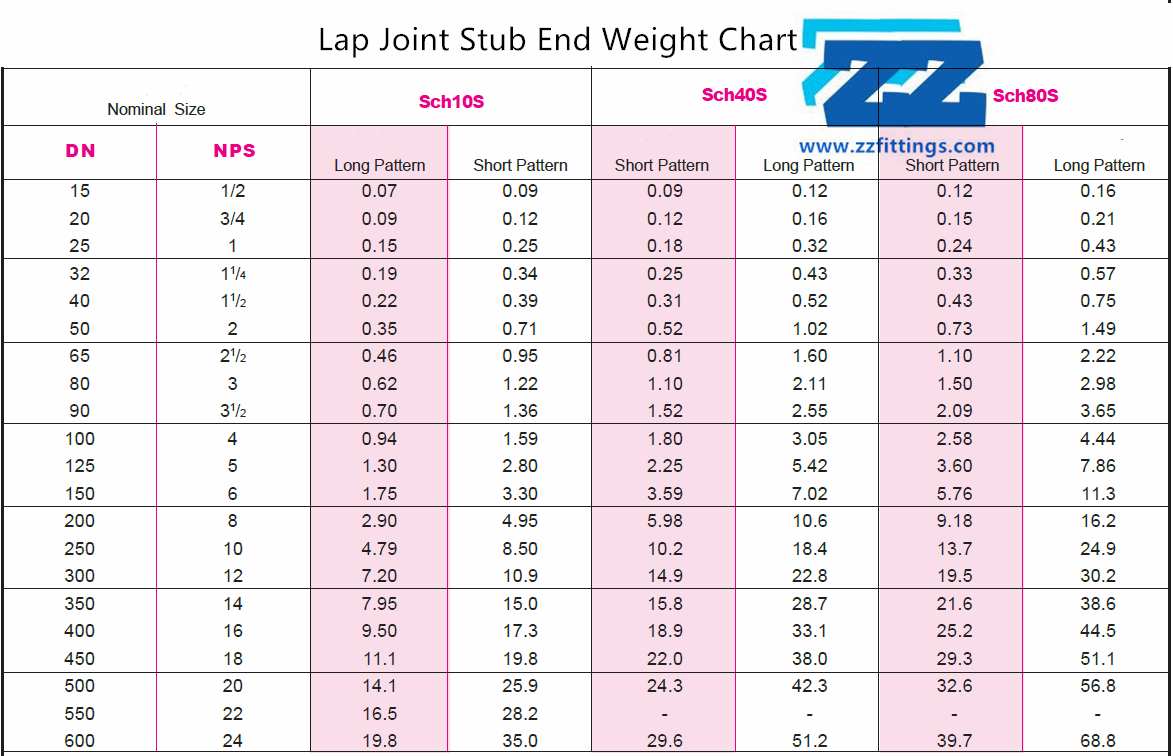

Lap Joint Stub End Weights

Lap Joint Stub End Weight Chart

Advantages of Stub Ends

- Reduce the total cost of flanged joints for piping systems in high material grades.

- Speed up the installation process, as the lap joint flange can be rotated to facilitate the alignment of the bolt holes.

Inspection of Carbon Steel Pipe Fittings

Check the marking. Such as name, size, schedule, grade, standard and Heat No.

Measure the dimensions. Such as outside diameter, thickness, height or length.

Ends of Short Type Stub End

- Beveled Ends

- Squared Ends

- Flanged Ends

- Grooved Ends

- Threaded Ends

Chemical Properties of ASTM A234 WPB & WPC

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

- For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

- The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

- The sum of Cr and Mo shall not exceed 0.32%.

- The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Mechanical Properties of ASTM A234 WPB / C

| Tensile Strength | Yield Strength | Elongation |

| 415 – 585 (Mpa) | 240 (Mpa) | 30 (%) |

- Longitudinal E=48t+15.00

- Transverse E=32t+10.00

- E = elongation in 2in [50mm], %

- t = actual thickness of specimen, in [mm]

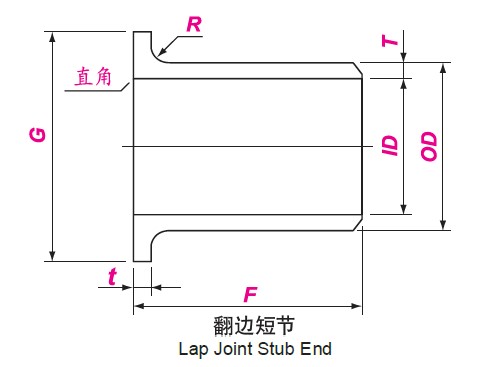

Drawing & Specification for Lap Joint Stub End

Lap Joint Stub End Drawing

- When the short type is used on the large flanges with PN 50 and PN 110(300 and 600LB)and on flanges

with PN 150(900LB)and above,or the long type is used on the larger flange with PN260 and PN420(1500 and 2500LB),the length of the cylinder may be added to be added to be feasible the welding,the adding length shall be negotiated by manufacturer and purchaser. - The thickness of joint shall be added if the TG and MFM contact surface of flange are used, and the adding thickness shall increase (not be included in)the base length F.

- The radius of fillet R(type A)shall conform to the ones of loose flanges according to GB/T 9118.1~9118.2 or ASME B16.5.The radius of fillet R(type B)is only applied for the standards of MSS SP-43 with short length F.

- The lap joint diameter G shall conform to the standard machined face indicated in ASME B16.5,and the back of joint shall be machined to conform to the surface of installation.When RJ used,the size K specified in ASME B 16.5 Shall apply.

- The minimum lap joint thickness t shall not be less than the nominal pipe wall thickness.

| Nominal Size | OD of Cylinder | Length | Radius of Fillet | Diameter of Lap | ||||

|---|---|---|---|---|---|---|---|---|

| DN | NPS | OD | F | R | ||||

| Max. | Min. | Long | Short | A | B | G | ||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 |

| 32 | 1 1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 |

| 40 | 1 1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 |

| 65 | 2 1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 |

| 90 | 3 1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 |

| 250 | 10 | 227.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 64 |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 |

8″ Equal Tee ASTM A860 WPHY 65

8" SCH XXS EQUAL TEE SEAMLESS BW ASTM A860 WPHY 65 ASME B16.9

USD190 USD185

Stainless Steel Bushings

3/4 x 1/2 NPT Stainless Steel 304L Flush Bushing Reducer ASME B16.11

USD6 USD5

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55