- Home

- Blog Custom Layout

- Steel Pipe Nipples

- Threaded Pipe Nipples

Threaded Pipe Nipples

USD2.5 USD2

Nipple 1/2" Sch 80 BSPP TBE L=100MM Galvanized API 5LB ASME B16.11

- General Details

- Technical Info

- Documents

- Related Products

Carbon Steel Threaded Fittings

1/2″ Threaded Pipe Nipples are manufactured by high quality carbon steels with a galvanized finish, also available in extensive range of dimensions.

Pipe Nipples are a short piece of pipe with external threaded end, it is commonly used in small diameter pipeline within 4 inch to connect pipes.

The threads at two ends can be same or different types, such as NPT thread to BSP thread nipples are also exist.

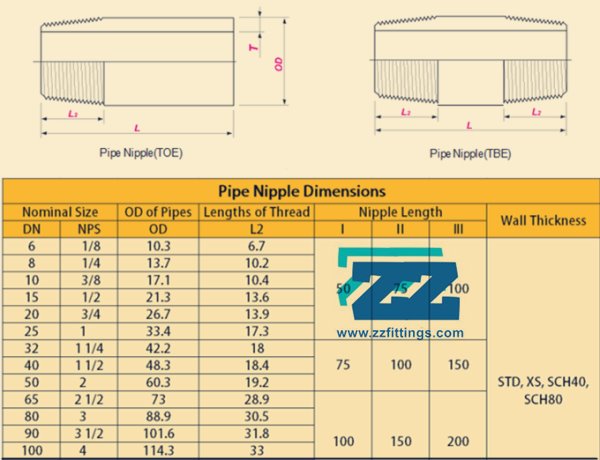

Threaded Pipe Nipples Dimensions

Threaded Pipe Nipples Dimensions

Standard: ASME B16.11, BS 3799

Diameter: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Rating: STD/SCH40, XS/Sch 80.

End Type: TBE, TOE, Male, Female

Thread Type: NPT, BSPP, BSPT, PF, PT

Surface: Anti-rust Oil, Galvanized or PE Coated.

Material Grades of BSP Threaded Nipple

Stainless Steel: ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321

Alloy Steel: ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel: ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760

Carbon Steel: ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Pipe Nipple Weight Chart

TOE or TBE Pipe Nipple are usually with BSPP and NPT threads. The thickness is usually used in Schedule 80 and 160, and common length are 100mm, 150mm or customized.

| Nominal Size | Weight/kg | ||

|---|---|---|---|

| DN | NPS | SCH80/ L=100 | SCH160 / L= 100 |

| 6 | 1/8 | 0.05 | – |

| 8 | 1/4 | 0.08 | – |

| 10 | 3/8 | 0.11 | – |

| 15 | 1/2 | 0.16 | 0.2 |

| 20 | 3/4 | 0.22 | 0.3 |

| 25 | 1 | 0.33 | 0.5 |

| 32 | 1 1/4 | 0.45 | 0.6 |

| 40 | 1 1/2 | 0.55 | 0.75 |

| 50 | 2 | 0.76 | 1.1 |

| 65 | 2 1/2 | 1.15 | 1.5 |

| 80 | 3 | 1.55 | 2.2 |

| 100 | 4 | 2.25 | 3.5 |

Galvanized Pipe Fittings

Package

We marked all Pipe Nipple with Grade, Lot No, Size, Standard and Pressure. The workers surfaced all Galvanized Pipe Nipples with anti-rust oil, then sleeved forged steel threaded fittings into plastic bag individually, packed them in carton and wooden cases, finally bundled packages with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

Inspection

- Visual check the surface of carbon steel nipples. Such as dents, die marks, porosity, undercuts.

- Check the marking. Such as size, material code, material grade, thickness, heat No.

- Measure the dimensions. Such as outside diameter, thickness, length of thread.

- Test the thread of thread nipple with go/no go gauge.

- Test the galvanized thickness of forged fittings.

Advantages

- Good Quality

- Fast Delivery

- Safe Package

- Abundant Stock

- Reasonable Price

- Reliable Shipment

API 5L B SPECIFICATION

API 5L B SPECIFICATION

Swage Nipple A106

3 x 2 Inch Sch 40 Eccentric Swage Nipple NPTM x NPTF ASTM A106 B MSS-SP-95

USD26 USD25