On 23, April, we received an inquiry from Bolivia. This client sought for 400 pieces carbon steel 180 degree elbow in carbon steel with simple drawing attached.

180 Degree elbow is our products. Thus we offered our competitive quotation based on the drawing. Two months later, the customer showed us more accurate drawing, together with many photos showing the details of the elbow that they wanted. We inspected all the information offered updated quotation fulfilling customer’s requirements.

After reviewing our quotation, the client placed the order. And after reviewing our sample, we manufactured in quantity.

We took very detailed photos of the sample to make sure that’s what our client want.

What is 180 Degree Elbow

180 Degree elbow is a pipe fitting that bends the pipeline by 180 degrees. It is used when a large directional change is needed or when a pipeline needs to be reversed without creating back flow.

According to the bending radius, 180 degree elbow will be divided two types, which are long radius (LR) and short radius (SR). As the weld type, there are seamless are welded elbow. Usually, seamless butt weld elbow is more expensive than welded due to the good property.

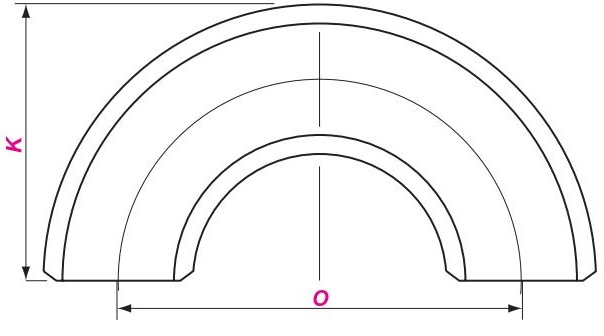

Dimension of ASME B16.9 180 Degree Elbow

ASME B 16.9 is set by the American Society of Mechanical Engineers. This standard governs scope, pressure ratings, size, marking, material, fitting dimensions, surface contours, end preparation, design proof tests, production tests, and tolerances.

180 Degree elbow produced according to ASME B16.9 have a wide range of sizes ranging 1/2 to 24. Common wall thickness pressure levels include Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, etc. Among them, the most commonly used are STD and XS.

| Size Range | 1/2″ – 24″ / DN15 – 600 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9 |

| Nominal Size | Outside Diameter at Bevel | Center to Center | Back to Face | |||

| 180 DEG Returns | ||||||

| DN | NPS | OD | O | K | ||

| LR | SR | LR | SR | |||

| 15 | 1/2 | 21.3 | 76 | – | 48 | – |

| 20 | 3/4 | 26.7 | 76 | – | 51 | – |

| 25 | 1 | 33.4 | 76 | 51 | 56 | 41 |

| 32 | 1-1/4 | 42.2 | 95 | 64 | 70 | 52 |

| 40 | 1-1/2 | 48.3 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 152 | 102 | 106 | 81 |

| 65 | 2-1/2 | 73 | 190 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 229 | 152 | 159 | 121 |

| 90 | 3-1/2 | 101.6 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 305 | 203 | 210 | 159 |

| 125 | 5 | 141.3 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.8 | 914 | 609 | 619 | 467 |

| 350 | 14 | 355.6 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | 1676 | 1118 | 1118 | 838 |

| 600 | 24 | 610 | 1829 | 1219 | 1219 | 914 |

Material

180 Degree elbow is made of different materials,stainless steel, carbon steel and alloy steel, depending on the application and the environmental factors.

Carbon Steel 180 Degree Elbow

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | Cb | V |

| ASTM A234 WPB | MIN | 0.29 | 0.10 | |||||||||

| MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | / | 0.08 |

Stainless Steel Grades

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | |||

| ASTM A403 WP904L | MIN | 23.00 | 19.00 | 4.00 | 1.00 | ||||||

| MAX | 0.02 | 2.00 | 0.045 | 0.035 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 | |

| ASTM A403 WP31254 | MIN | 17.50 | 19.50 | 6.00 | 0.18 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 0.25 | 1.0 | |

| ASTM A403 WP321 | MIN | 9.00 | 17.00 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 |

Duplex Stainless Steel Grades

| CHEMICAL | C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu |

| ASTM A815 UNS 32750 | 0.03 max | 1.2 max | 0.035 max | 0.020 max | 0.8 max | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 0.5 max |

Application

Petrochemical Industry

Thermal Power Generation Industry

The Pharmaceutical Industry

Food Processing Industry

Shipbuilding Industry

Chemical Industry

Nuclear Industry